Product Description

Basic Info.

| Product Description | ||||||

| Name: | PK BELT | |||||

| Feature | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance | |||||

| Quality | OE Quality /A+ | |||||

| Suitable for | Automotive/Motorcycle, Machinery, Marine, Mining Equipment, Agricultural Machinery, Car | |||||

| Samples time: | within 7days | |||||

| Imported material | ||||||

| Material | Rubber/CR/EPDM… | |||||

| Packing | Color box+ Cartons+Nylon bags | |||||

| Rang | 550-12000mm | |||||

| HS code | 457131000 | |||||

| Logo | Customized logo and package | |||||

| capacity | >300000pcs/mouth | |||||

| Size | from 3pk-12pk | |||||

| Compay profile | ||||||

| ZheJiang Spetop Industrial Co., Ltd. focusing on Automotive spare parts /material handling/ power transmission and industry application.

Our company was founded in 2571,has nearly 15 years in Automotive area. more than 70 employees, Main products including Automotive rubber belt, Timing Belt, PK belt, Fan Belt, Cogged V-Belts, wrapped V-Belt, Industrial belts etc. Used in automotive and industrial machine or Agriculture area……

|

||||||

| Our Advantages | ||||||

| ▄ Near HangZhou/HangZhou /HangZhou port | ||||||

| ▄ 12 production line for PK belt | ||||||

| ▄ 1000+ belt mold | ||||||

| ▄ Strong production capacity | ||||||

| ▄15 years on automotive belt area. profeesional and experiece | ||||||

| ▄ > 10 year exprot experience more than 25 countries exported | ||||||

| ▄ Professional QC and R&D system | ||||||

| ▄ OE quality control and fast delivery |

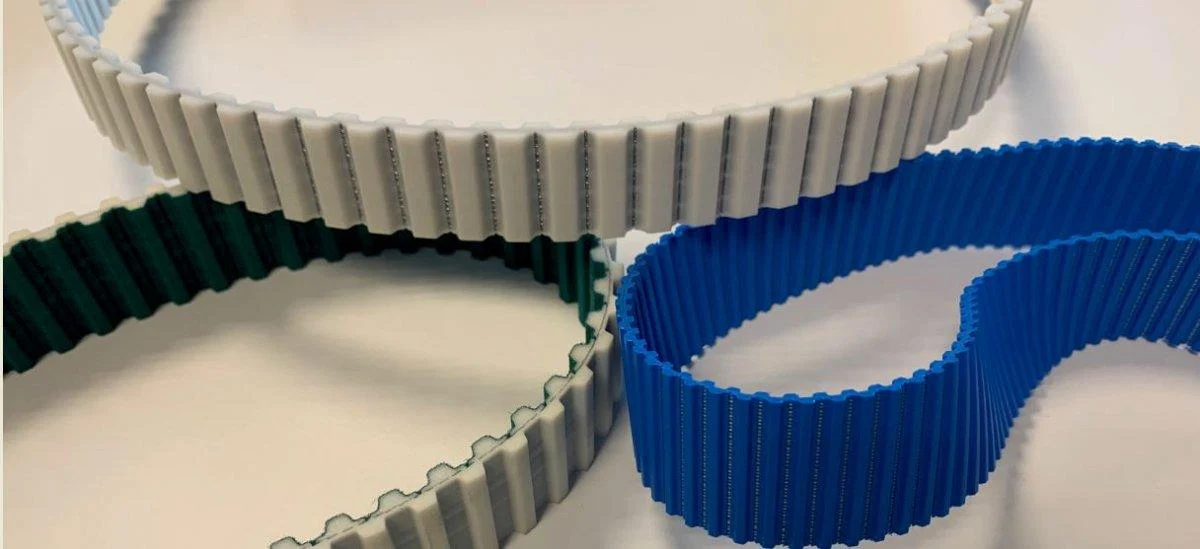

Detailed Photos

High-Quality Rubber Timing Belt for Auto Spare Parts

Introducing our high-quality rubber timing belt, designed to provide excellent flexibility and high power transmission efficiency. This advanced auto spare part is perfect for enhancing the performance of your engine.

One of the standout features of this timing belt is its reduced noise, ensuring a calm and soothing driving experience. The multiple longitudinal CZPT of the belt allow for efficient power transmission, while the larger contact surface area provides superior performance compared to V belts or flat belts.

Manufactured by ZheJiang Spetop Industrial Co., Ltd., a reliable supplier of rubber belts, this timing belt is made from EPDM rubber, known for its durability and reliability. It is the perfect choice for automotive timing belts and engine parts.

Upgrade your car’s engine with our high-quality rubber timing belt. Experience the benefits of improved power transmission, reduced noise, and enhanced flexibility. Trust in the expertise of ZheJiang Spetop Industrial Co., Ltd., a leading supplier of rubber belts for auto parts.

High-Quality Rubber Timing Belt for Auto Spare Parts

Introducing our high-quality rubber timing belt, designed to provide excellent flexibility and high power transmission efficiency. Made from a high-grade engineered rubber, this timing belt offers a longer service life and reduced noise, ensuring a smooth and quiet operation.

With a temperature range from -40ºC to +120ºC, this timing belt is suitable for various environments. It is oil, heat, ozone, and abrasion resistant, making it a reliable choice for your automotive needs.

Whether you’re looking for a timing belt for your car engine or auto spare parts, our rubber timing belt is the perfect solution. It is a reliable and high-quality option that meets the demands of the automotive industry.

Trust ZheJiang Spetop Industrial Co., Ltd., a reputable rubber belt supplier, to provide you with the best timing belt for your engine. Our advanced auto parts, including this timing belt, are designed to enhance the performance and efficiency of your vehicle.

Upgrade your engine with our high-quality rubber timing belt. Order now and experience the benefits of a smooth and efficient power transmission.

Specification

| Profile | Pb | h | a° |

| H | 1.6 | 3 | 40 |

| J | 2.34 | 4 | 40 |

| K | 3.56 | 6 | 40 |

| L | 4.7 | 10 | 40 |

| M | 9.4 | 17 | 40 |

| Factory workshop Show |

Packaging & Shipping

Product Name: High-Quality Rubber Timing Belt for Auto Spare Parts

Company Name: ZheJiang Spetop Industrial Co., Ltd.

Keywords: Rubber Timing Belt, Auto Spare Parts, High-Quality, Advance Auto Parts, Engine Parts, Pk Belt, Rubber Belts, EPDM Rubber Belt, Rubber Belt Supplier, Reliable Pk Belt, Timing Belt for Car, Car Engine Belt, Automotive Timing Belt, Pk Belt Supplier, Rubber Engine Belt, Auto Timing Belt, Engine Timing Belt, Advancement Auto Parts, Pk Rubber Belt, Auto Engine Belt, Rubber Belt for Auto Parts

Discover our high-quality rubber timing belt, designed for auto spare parts. Made by ZheJiang Spetop Industrial Co., Ltd., a reliable supplier of rubber belts. Perfect for engine parts and compatible with various car models. Trust in our advanced technology and choose the best for your automotive needs.

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | Yes |

| Type: | Cooling System |

| Material: | Rubber |

| Muffler Type: | Without Noise |

| Deck: | Double |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications?

V-belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of V-belts in various applications. By maintaining proper belt tension, mitigating belt slippage, reducing wear, and minimizing the risk of belt failure, tensioners contribute to improved efficiency and extended belt life. Here’s a detailed explanation of how V-belt tensioners enhance the overall efficiency and lifespan of V-belts:

- Optimal Belt Tension:

- Reduced Belt Slippage:

- Wear Reduction:

- Vibration and Noise Damping:

- Prevention of Belt Failure:

V-belts operate most efficiently when they are running at the correct tension. Over-tensioned or under-tensioned belts can lead to problems such as excessive heat generation, increased wear, and reduced power transmission. V-belt tensioners ensure that the belts are properly tensioned by applying the right amount of force to maintain the desired tension level. This optimizes the power transfer efficiency and minimizes energy losses, resulting in improved overall system efficiency.

Proper tensioning provided by V-belt tensioners helps to minimize belt slippage, which is a common issue in V-belt drive systems. Belt slippage occurs when the belt slips on the pulleys, leading to a loss of power transmission efficiency. Tensioners maintain the necessary tension in the belt, ensuring a positive grip between the belt and the pulleys. By reducing slippage, tensioners help maximize power transfer, improve system efficiency, and prevent premature belt wear due to excessive slipping.

V-belt tensioners help reduce wear on the belts by ensuring proper alignment and tension. Misaligned or poorly tensioned belts can experience increased wear, resulting in premature belt failure. Tensioners keep the belts aligned and tensioned correctly, minimizing lateral movement and excessive belt wear. By reducing wear, tensioners contribute to the extended lifespan of the belts and reduce the need for frequent belt replacements, resulting in cost savings for the application.

V-belt tensioners can also help dampen vibrations and reduce noise in V-belt drive systems. Vibration and noise can occur due to belt oscillation or irregular belt-pulley contact. Tensioners stabilize the belt tension, reducing belt vibrations and associated noise. This not only improves the overall system performance but also enhances the working environment by reducing noise levels.

By maintaining optimal tension and reducing wear, V-belt tensioners help prevent belt failure. Belt failure can result in unexpected downtime, increased maintenance costs, and productivity losses. Tensioners ensure that the belts are properly tensioned and aligned, reducing the risk of belt fatigue, cracking, or premature breakage. This enhances the overall reliability and longevity of the belts, allowing for uninterrupted operation and improved application performance.

In summary, V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications by maintaining optimal tension, reducing belt slippage, minimizing wear, damping vibrations and noise, and preventing belt failure. These benefits result in improved power transmission efficiency, extended belt life, reduced maintenance requirements, and enhanced system reliability. By incorporating well-designed and properly adjusted tensioners, applications can optimize the performance and longevity of V-belts, leading to increased productivity and cost savings.

How do innovations and advancements in V-belt tensioner technology impact their use?

Innovations and advancements in V-belt tensioner technology have a significant impact on their use, leading to improved performance, increased reliability, and enhanced efficiency in various applications. Here’s a detailed explanation of how innovations and advancements in V-belt tensioner technology impact their use:

- Enhanced Tensioning Mechanisms:

- Increased Durability and Reliability:

- Reduced Friction and Energy Losses:

- Integration of Diagnostic and Monitoring Features:

- Application-Specific Customization:

New technologies and design innovations have led to the development of enhanced tensioning mechanisms in V-belt tensioners. These mechanisms offer improved accuracy and consistency in applying the desired tension force to the belts. Advanced tensioner designs may incorporate features such as self-adjusting mechanisms, automatic tension control, or adaptive tensioning systems. These advancements simplify the tensioning process, reduce manual adjustments, and ensure optimal tension levels, leading to improved system performance and reduced maintenance requirements.

Advancements in materials, manufacturing processes, and engineering techniques have resulted in V-belt tensioners with increased durability and reliability. New materials with improved strength and wear resistance, such as advanced polymers or specialized alloys, are being utilized in tensioner construction. Additionally, innovative manufacturing methods allow for tighter tolerances, precise assembly, and better overall quality control. These advancements result in tensioners that can withstand higher loads, resist wear and fatigue, and operate reliably even in demanding environments, enhancing the longevity and reliability of V-belt systems.

New technologies and advancements in V-belt tensioner design have focused on reducing friction and energy losses during power transmission. Friction-reducing coatings, specialized bearing systems, and optimized contact surfaces are employed to minimize energy losses due to belt-pulley interaction. These advancements result in improved power transmission efficiency, reduced heat generation, and lower energy consumption. By reducing friction and energy losses, innovative tensioner technologies contribute to energy savings, lower operating costs, and improved overall system efficiency.

Advancements in V-belt tensioner technology include the integration of diagnostic and monitoring features. Tensioners may incorporate sensors or indicators that provide real-time data on tension levels, belt wear, or system performance. This allows users to monitor the condition of the tensioner and the entire power transmission system, enabling proactive maintenance and preventing unexpected failures. Diagnostic and monitoring capabilities enhance system reliability, optimize maintenance schedules, and reduce downtime, leading to improved operational efficiency.

Advancements in V-belt tensioner technology have facilitated application-specific customization. Manufacturers can now design tensioners to meet the unique requirements of different industries and applications. Customizable features include tensioning force, size, mounting options, and specialized coatings. This flexibility allows for better integration into specific systems, addressing space constraints, load demands, and environmental conditions. Application-specific customization improves overall system performance, reliability, and compatibility.

In summary, innovations and advancements in V-belt tensioner technology have a profound impact on their use. Enhanced tensioning mechanisms, increased durability and reliability, reduced friction and energy losses, integration of diagnostic and monitoring features, and application-specific customization all contribute to improved performance, reliability, efficiency, and compatibility. These advancements enable more efficient power transmission, longer service life, reduced maintenance requirements, and enhanced overall performance of V-belt systems in various industrial and automotive applications.

Can you explain the significance of proper tensioning in V-belt-driven machinery and equipment?

Proper tensioning plays a significant role in V-belt-driven machinery and equipment. It is crucial for ensuring efficient power transmission, preventing slippage, and maximizing the performance and reliability of the V-belt system. Here’s a detailed explanation of the significance of proper tensioning in V-belt-driven machinery and equipment:

- Efficient Power Transmission:

- Preventing Slippage:

- Extending Belt Life:

- Reducing Maintenance and Downtime:

- Enhancing System Reliability:

Proper tensioning is essential for efficient power transmission in V-belt-driven systems. When the V-belt is properly tensioned, it maintains a firm grip on the pulleys, allowing for effective transfer of rotational energy from the driving pulley to the driven components. The correct tension ensures that power is transmitted without slippage, minimizing energy losses and maximizing the system’s efficiency. By maintaining proper tension, V-belt-driven machinery and equipment can achieve optimal power transfer and operate at their intended speeds and performance levels.

One of the primary purposes of proper tensioning is to prevent slippage between the V-belt and the pulleys. Slippage can occur when the tension in the V-belt is inadequate or when the belt is subjected to excessive loads. Insufficient tension or overloading can cause the belt to lose traction with the pulleys, resulting in reduced power transmission, decreased efficiency, and potential damage to the belt and other system components. Proper tensioning ensures that the V-belt remains tightly engaged with the pulleys, preventing slippage and maintaining reliable power transmission.

Proper tensioning is essential for extending the life of the V-belt. When a V-belt is under excessive tension, it can experience accelerated wear and premature failure due to increased stress on the belt and the pulleys. On the other hand, insufficient tension can lead to belt vibration, excessive flexing, and localized wear, reducing the belt’s lifespan. By maintaining the correct tension, V-belt-driven machinery and equipment can minimize wear, distribute the load evenly across the belt and pulleys, and promote optimal belt life. Proper tensioning contributes to reducing maintenance costs and downtime associated with belt replacement.

Proper tensioning helps reduce maintenance requirements and downtime in V-belt-driven systems. When the V-belt is under the correct tension, it operates smoothly without slippage or excessive wear. This minimizes the need for frequent adjustments, re-tensioning, and belt replacements. By maintaining the proper tension, V-belt-driven machinery and equipment can operate reliably, with reduced risks of unexpected belt failures or performance issues. Proper tensioning contributes to increased system uptime, improved productivity, and reduced maintenance costs.

Proper tensioning enhances the overall reliability of V-belt-driven machinery and equipment. When the V-belt is correctly tensioned, it operates within its designed parameters, ensuring that the system components are subjected to the appropriate forces and loads. This reduces the risk of belt slippage, excessive wear, and premature component failure. By promoting reliable power transmission, minimizing the potential for system malfunctions, and extending the lifespan of the V-belt and other system components, proper tensioning contributes to the overall reliability and longevity of V-belt-driven machinery and equipment.

In summary, proper tensioning is of significant importance in V-belt-driven machinery and equipment. It ensures efficient power transmission, prevents slippage, extends the life of the V-belt, reduces maintenance requirements and downtime, and enhances the overall reliability of the system. By maintaining the correct tension, V-belt-driven machinery and equipment can achieve optimal performance, maximize energy efficiency, and minimize the risks of belt failure or system malfunctions.

editor by CX 2024-03-07