Product Description

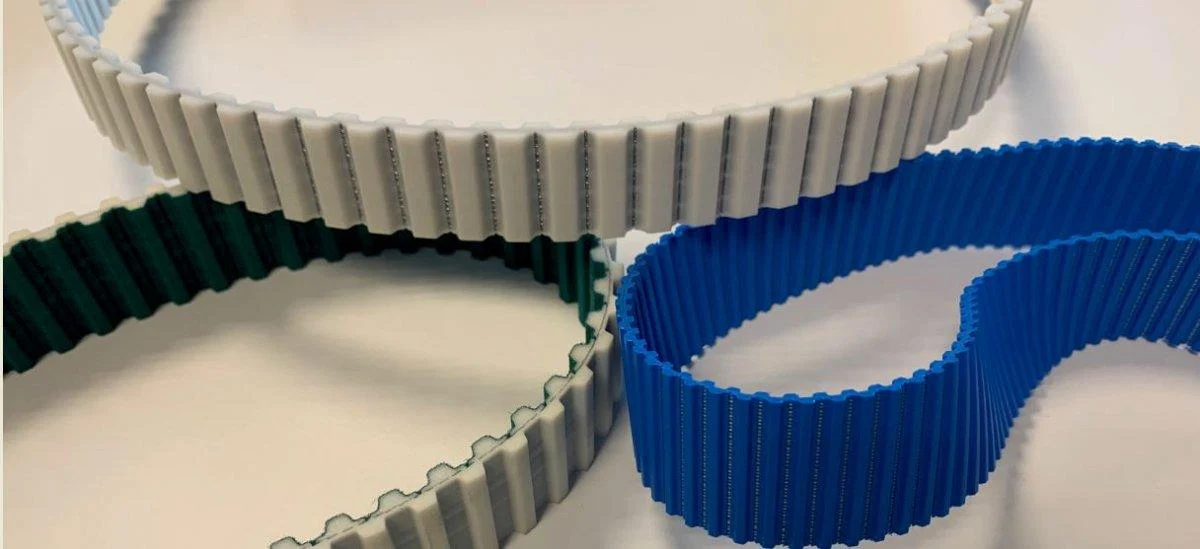

Banded V Belts

Banded cog belt is consist of several cog-belt joined together which is high stability and smooth running on the toughest drives.

Production Features

Banded cog belt is designed for automotive application used, and also available for industrial use. such as, bus and truck. Agriculture Machinery also available.

Features:

- Large intensity, high flexbility, good durability

- Special bottom rubber used, small elongation and long service life

- Excellent heat-resistance, oil-proof, and wearing resistance

Advantages:

- Suitable for band pulley with minor diameter

- Safe performance can be guaranteed during high-speed oepration

- strict and scientic management team

Product specification of Carbon Belts

- Header

- Separator

- Launder

- Peeling

- Underpin Driver

- Driving Power System

- Main Clutch

- Hydraulic Pump

- Reverse Box

-

Variable Speed Gearing

MACHINES

- Combine Harvesters

- Front-End Equipment

- Cane Harvesters

- Cotton Harvesters

- Self-Propelled Forage Harvesters

- Hay and Forage Heads

- Balers

- Mowers

Factory

ZHangZhoug Sanxing Rubber Belt Co., Ltd. was established in 1989. 350 workers, 8500 square metre non-dust workshops, 34 years experience, We got ISO/TS16949:2002(renamed as IATF16949:2016)and ISO9001:2015, all products pass RoHS test by TUV so as to effectively control the quality, and provide customers with guaranteed high-quality products

Sanxing company possesses a complete set of advanced production and testing equipments. We specializes in designing and producing Raw Edge Cogged V-Belt, Poly V-Belt, Roll Mill Belt, Timing Belt, Polychain Carbon Timing Belts, Agricultural belts, and Industrial Belts and other related rubber products. These products are widely used in the area of automotive, scooter, industrial and agricultural machinery, household appliances, etc. We have high reputations among our domestic and overseas customers.

Environmental &Quality Certificate

Exhibition

Delivery,Shipping and Service

What about the delivery time?

2-3 days for sample, 45 working days for mass production. Depends on qty/sizes

The payment term

TT / LC /west union / PayPal / cash.

Payment=1000USD, 50% T/T in advance ,balance before shipment.

Package

Standard export cartons, box dimension: 470x400x460mm

Shipping

Sea/ Air/ UPS/DHL/TNT/FedEx

After Service

We will replace the belts if customer receives the defective belts.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 10 to 20 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Electronic Security Devices |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Harvester |

| Material: | Aluminum |

| Power Source: | Diesel |

| Weight: | 5lbs |

| After-sales Service: | 24 Hours |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

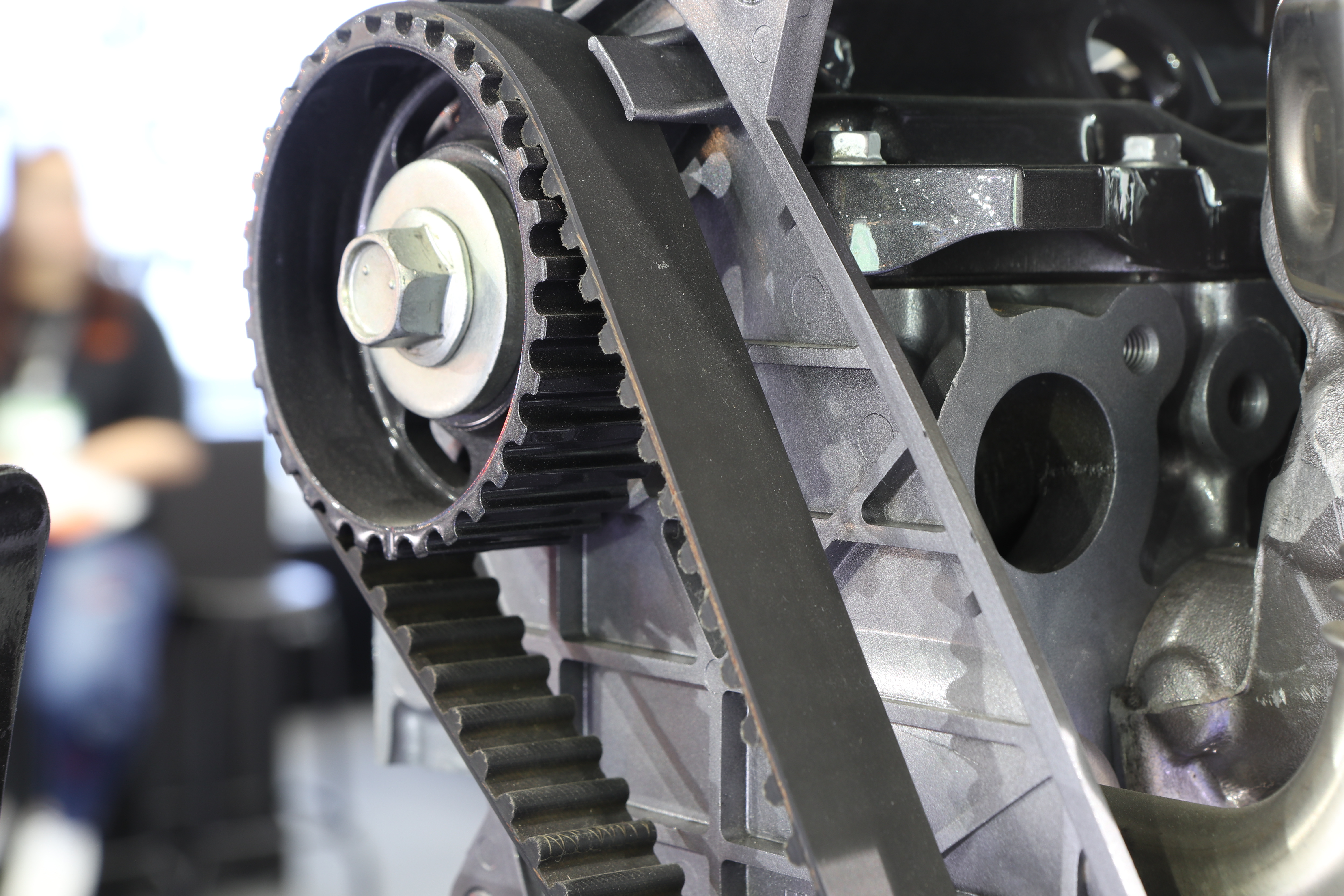

Can you explain the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery?

Using V-belt tensioners in machinery offers several benefits in preventing slippage and optimizing power transmission. By maintaining proper belt tension, minimizing belt slippage, and ensuring consistent power transfer, tensioners contribute to improved efficiency, reduced energy losses, and enhanced overall performance. Here’s a detailed explanation of the benefits of using V-belt tensioners:

- Prevention of Belt Slippage:

- Optimized Power Transmission:

- Improved Efficiency:

- Reduced Wear and Maintenance:

- Enhanced System Reliability:

V-belt tensioners play a critical role in preventing belt slippage in machinery. Belt slippage occurs when the belt slips on the pulleys, resulting in a loss of power transmission efficiency and decreased performance. Tensioners apply the appropriate tension to the V-belt, ensuring a positive grip between the belt and the pulleys. This minimizes or eliminates slippage, allowing for efficient power transfer from the driving pulley to the driven pulley.

Proper tensioning provided by V-belt tensioners optimizes power transmission in machinery. When the V-belt is properly tensioned, it maintains a consistent contact area with the pulleys, maximizing the frictional grip. This efficient power transfer ensures that the input power from the driving pulley is effectively transmitted to the driven pulley, minimizing energy losses and maximizing the overall system efficiency.

By preventing slippage and ensuring optimal power transmission, V-belt tensioners contribute to improved efficiency in machinery. Slippage leads to energy losses, as power is wasted in overcoming the slipping motion instead of being transferred to the driven components. Tensioners maintain the necessary tension in the V-belt, reducing slippage and maximizing power transfer efficiency. This results in improved overall system efficiency, reduced energy consumption, and cost savings over time.

V-belt tensioners help reduce wear on the V-belts and associated components, leading to reduced maintenance requirements. Proper tensioning minimizes belt movement and excessive wear, extending the lifespan of the belts. By preventing slippage, tensioners also reduce the risk of belt damage, such as excessive heat generation or premature wear due to friction. This results in longer belt life, fewer replacements, and reduced maintenance costs for the machinery.

Using V-belt tensioners enhances the reliability of machinery by ensuring consistent power transmission. When the V-belts are properly tensioned, the risk of unexpected belt slippage or failure is significantly reduced. Reliable power transmission minimizes downtime, production interruptions, and the associated costs. Tensioners play a crucial role in maintaining the required tension in the belts, contributing to the overall reliability and uninterrupted operation of the machinery.

In summary, the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery include the prevention of belt slippage, optimized power transfer efficiency, improved overall system efficiency, reduced wear and maintenance, and enhanced system reliability. By properly tensioning the V-belts, tensioners ensure efficient power transmission, reduce energy losses, and extend the lifespan of the belts, resulting in improved performance and cost savings for machinery applications.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery where optimal belt functionality is essential. The design and characteristics of V-belts make them suitable for applications that require high torque transmission, durability, and reliable power transfer. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are commonly used:

- Automotive Industry:

- Industrial Machinery:

- HVAC Systems:

- Power Generation:

- Agricultural Machinery:

The automotive industry is one of the primary sectors where V-belt tensioners are commonly utilized. V-belts are used in automotive engines to drive various components such as the alternator, water pump, power steering pump, and air conditioning compressor. V-belt tensioners ensure proper tensioning of the belts, allowing for efficient power transmission and reliable operation of these critical automotive systems.

V-belt tensioners find extensive use in a wide range of industrial machinery and equipment. Industries such as manufacturing, mining, agriculture, construction, and material handling rely on V-belt-driven systems for power transmission. V-belts are commonly found in machinery such as conveyor systems, pumps, compressors, fans, blowers, and generators. V-belt tensioners play a crucial role in maintaining optimal tension, preventing belt slippage, and ensuring reliable and efficient operation of these industrial systems.

Heating, ventilation, and air conditioning (HVAC) systems often incorporate V-belt-driven components. V-belt tensioners are used to ensure proper tensioning of the belts in HVAC systems, which may include components like HVAC fans, blowers, and pumps. The tensioners help maintain reliable power transmission, prevent belt slippage, and ensure efficient operation of the HVAC equipment, contributing to effective climate control in various settings such as commercial buildings, residential complexes, and industrial facilities.

In power generation facilities, V-belt tensioners are commonly employed in equipment such as generators and turbines. V-belts are used to transmit power from the prime mover to the generator or turbine, and the tensioners ensure proper belt tension to maintain efficient power transfer. V-belt tensioners play a vital role in power generation applications, helping to optimize performance, prevent belt slippage, and ensure reliable operation of the power generation equipment.

Agricultural machinery and equipment, including tractors, combines, and agricultural implements, often rely on V-belt-driven systems. V-belts are used to transfer power to various agricultural components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners in agricultural machinery help maintain the proper tension in the belts, ensuring efficient power transmission and reliable operation in demanding agricultural environments.

V-belt tensioners are also utilized in other industries and machinery such as marine applications (e.g., marine engines and propulsion systems), construction equipment (e.g., concrete mixers and excavators), and woodworking machinery (e.g., saws and planers). These tensioners are designed to accommodate the specific requirements of each industry and application, ensuring optimal belt functionality, reliable power transmission, and extended belt life.

editor by CX 2024-03-08