Product Description

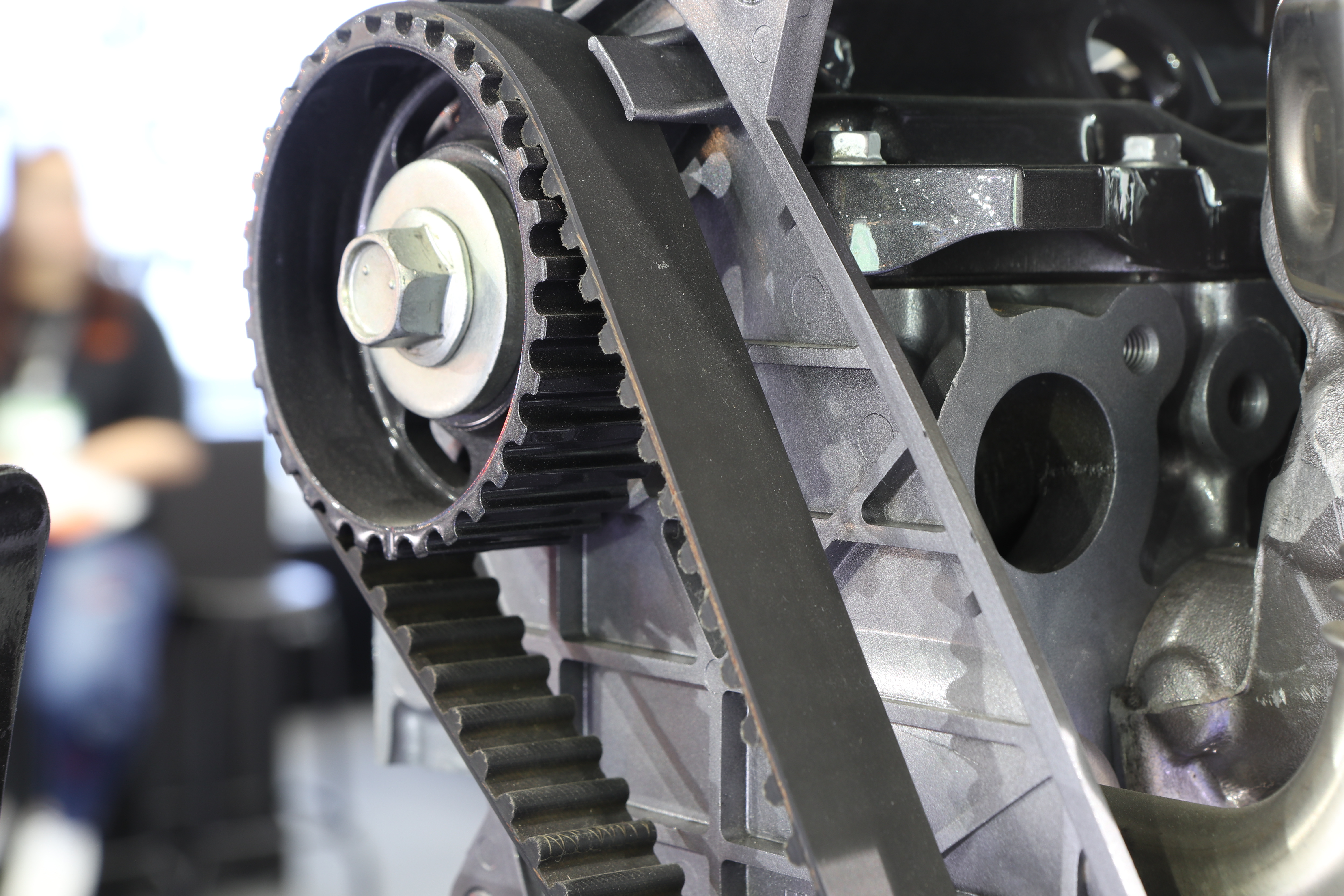

Banded V Belts

Banded cog belt is consist of several cog-belt joined together which is high stability and smooth running on the toughest drives.

Production Features

Banded cog belt is designed for automotive application used, and also available for industrial use. such as, bus and truck. Agriculture Machinery also available.

Features:

- Large intensity, high flexbility, good durability

- Special bottom rubber used, small elongation and long service life

- Excellent heat-resistance, oil-proof, and wearing resistance

Advantages:

- Suitable for band pulley with minor diameter

- Safe performance can be guaranteed during high-speed oepration

- strict and scientic management team

Product specification of Carbon Belts

- Header

- Separator

- Launder

- Peeling

- Underpin Driver

- Driving Power System

- Main Clutch

- Hydraulic Pump

- Reverse Box

-

Variable Speed Gearing

MACHINES

- Combine Harvesters

- Front-End Equipment

- Cane Harvesters

- Cotton Harvesters

- Self-Propelled Forage Harvesters

- Hay and Forage Heads

- Balers

- Mowers

Factory

ZHangZhoug Sanxing Rubber Belt Co., Ltd. was established in 1989. 350 workers, 8500 square metre non-dust workshops, 34 years experience, We got ISO/TS16949:2002(renamed as IATF16949:2016)and ISO9001:2015, all products pass RoHS test by TUV so as to effectively control the quality, and provide customers with guaranteed high-quality products

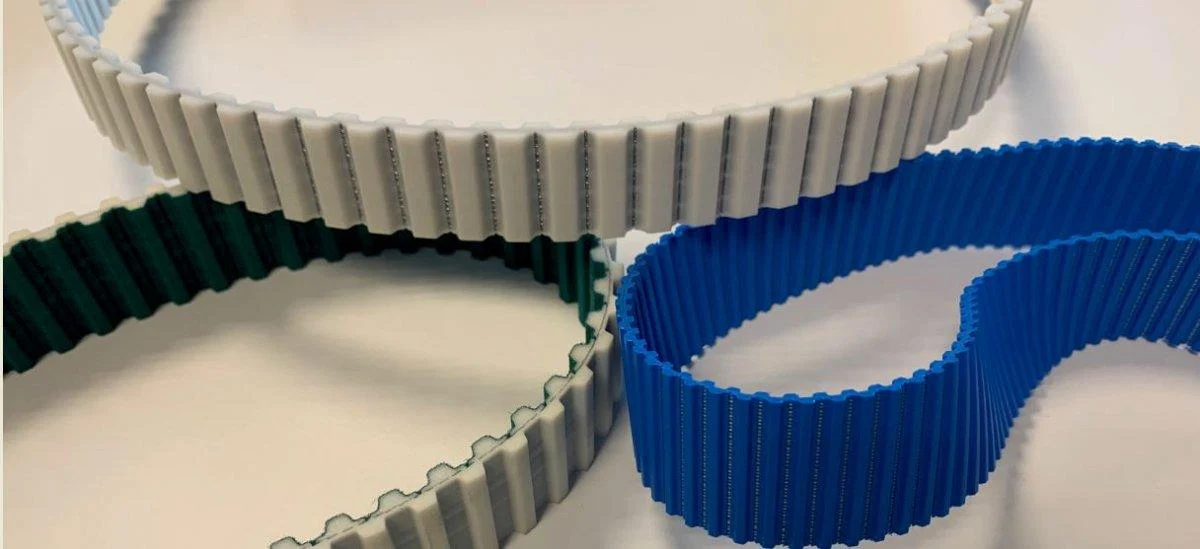

Sanxing company possesses a complete set of advanced production and testing equipments. We specializes in designing and producing Raw Edge Cogged V-Belt, Poly V-Belt, Roll Mill Belt, Timing Belt, Polychain Carbon Timing Belts, Agricultural belts, and Industrial Belts and other related rubber products. These products are widely used in the area of automotive, scooter, industrial and agricultural machinery, household appliances, etc. We have high reputations among our domestic and overseas customers.

Environmental &Quality Certificate

Exhibition

Delivery,Shipping and Service

What about the delivery time?

2-3 days for sample, 45 working days for mass production. Depends on qty/sizes

The payment term

TT / LC /west union / PayPal / cash.

Payment=1000USD, 50% T/T in advance ,balance before shipment.

Package

Standard export cartons, box dimension: 470x400x460mm

Shipping

Sea/ Air/ UPS/DHL/TNT/FedEx

After Service

We will replace the belts if customer receives the defective belts.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 10 to 20 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Electronic Security Devices |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Harvester |

| Material: | Aluminum |

| Power Source: | Diesel |

| Weight: | 5lbs |

| After-sales Service: | 24 Hours |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery?

Using V-belt tensioners in machinery offers several benefits in preventing slippage and optimizing power transmission. By maintaining proper belt tension, minimizing belt slippage, and ensuring consistent power transfer, tensioners contribute to improved efficiency, reduced energy losses, and enhanced overall performance. Here’s a detailed explanation of the benefits of using V-belt tensioners:

- Prevention of Belt Slippage:

- Optimized Power Transmission:

- Improved Efficiency:

- Reduced Wear and Maintenance:

- Enhanced System Reliability:

V-belt tensioners play a critical role in preventing belt slippage in machinery. Belt slippage occurs when the belt slips on the pulleys, resulting in a loss of power transmission efficiency and decreased performance. Tensioners apply the appropriate tension to the V-belt, ensuring a positive grip between the belt and the pulleys. This minimizes or eliminates slippage, allowing for efficient power transfer from the driving pulley to the driven pulley.

Proper tensioning provided by V-belt tensioners optimizes power transmission in machinery. When the V-belt is properly tensioned, it maintains a consistent contact area with the pulleys, maximizing the frictional grip. This efficient power transfer ensures that the input power from the driving pulley is effectively transmitted to the driven pulley, minimizing energy losses and maximizing the overall system efficiency.

By preventing slippage and ensuring optimal power transmission, V-belt tensioners contribute to improved efficiency in machinery. Slippage leads to energy losses, as power is wasted in overcoming the slipping motion instead of being transferred to the driven components. Tensioners maintain the necessary tension in the V-belt, reducing slippage and maximizing power transfer efficiency. This results in improved overall system efficiency, reduced energy consumption, and cost savings over time.

V-belt tensioners help reduce wear on the V-belts and associated components, leading to reduced maintenance requirements. Proper tensioning minimizes belt movement and excessive wear, extending the lifespan of the belts. By preventing slippage, tensioners also reduce the risk of belt damage, such as excessive heat generation or premature wear due to friction. This results in longer belt life, fewer replacements, and reduced maintenance costs for the machinery.

Using V-belt tensioners enhances the reliability of machinery by ensuring consistent power transmission. When the V-belts are properly tensioned, the risk of unexpected belt slippage or failure is significantly reduced. Reliable power transmission minimizes downtime, production interruptions, and the associated costs. Tensioners play a crucial role in maintaining the required tension in the belts, contributing to the overall reliability and uninterrupted operation of the machinery.

In summary, the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery include the prevention of belt slippage, optimized power transfer efficiency, improved overall system efficiency, reduced wear and maintenance, and enhanced system reliability. By properly tensioning the V-belts, tensioners ensure efficient power transmission, reduce energy losses, and extend the lifespan of the belts, resulting in improved performance and cost savings for machinery applications.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery where optimal belt functionality is essential. The design and characteristics of V-belts make them suitable for applications that require high torque transmission, durability, and reliable power transfer. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are commonly used:

- Automotive Industry:

- Industrial Machinery:

- HVAC Systems:

- Power Generation:

- Agricultural Machinery:

The automotive industry is one of the primary sectors where V-belt tensioners are commonly utilized. V-belts are used in automotive engines to drive various components such as the alternator, water pump, power steering pump, and air conditioning compressor. V-belt tensioners ensure proper tensioning of the belts, allowing for efficient power transmission and reliable operation of these critical automotive systems.

V-belt tensioners find extensive use in a wide range of industrial machinery and equipment. Industries such as manufacturing, mining, agriculture, construction, and material handling rely on V-belt-driven systems for power transmission. V-belts are commonly found in machinery such as conveyor systems, pumps, compressors, fans, blowers, and generators. V-belt tensioners play a crucial role in maintaining optimal tension, preventing belt slippage, and ensuring reliable and efficient operation of these industrial systems.

Heating, ventilation, and air conditioning (HVAC) systems often incorporate V-belt-driven components. V-belt tensioners are used to ensure proper tensioning of the belts in HVAC systems, which may include components like HVAC fans, blowers, and pumps. The tensioners help maintain reliable power transmission, prevent belt slippage, and ensure efficient operation of the HVAC equipment, contributing to effective climate control in various settings such as commercial buildings, residential complexes, and industrial facilities.

In power generation facilities, V-belt tensioners are commonly employed in equipment such as generators and turbines. V-belts are used to transmit power from the prime mover to the generator or turbine, and the tensioners ensure proper belt tension to maintain efficient power transfer. V-belt tensioners play a vital role in power generation applications, helping to optimize performance, prevent belt slippage, and ensure reliable operation of the power generation equipment.

Agricultural machinery and equipment, including tractors, combines, and agricultural implements, often rely on V-belt-driven systems. V-belts are used to transfer power to various agricultural components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners in agricultural machinery help maintain the proper tension in the belts, ensuring efficient power transmission and reliable operation in demanding agricultural environments.

V-belt tensioners are also utilized in other industries and machinery such as marine applications (e.g., marine engines and propulsion systems), construction equipment (e.g., concrete mixers and excavators), and woodworking machinery (e.g., saws and planers). These tensioners are designed to accommodate the specific requirements of each industry and application, ensuring optimal belt functionality, reliable power transmission, and extended belt life.

editor by CX 2024-03-08

China Annilte 15t Timing Belt Drive Pulley Gear Hdt 5m Bore 5 Pitch 5mm Wide 16mm Htd Belts and Pulleys V Belt Pulley Chemical Industry with Good quality

Merchandise Description

|

Merchandise Identify |

Steel Timing Pulley |

|

Guarantee |

1 calendar year |

|

Certification |

ISO |

|

Relevant Industries |

Production Plant, Equipment Repair Outlets, Farms, Building operates , Other, Textile Equipment |

|

Customized assist |

OEM, ODM |

|

Area of Origin |

China |

|

Brand Title |

Annilte |

|

Item name |

Timing Belt Pulley |

Gain:

1. Manufacturing facility immediately offer , we can keep on to provide a steady supply

two. Several many years manufacture encounter , prime top quality confirmed by expert personnel, handling method and standing of facilities.

3. Aggressive and sensible price

4. OEM provider, we can do as your drawings or samples

five. High quality Guarantee, 100% examine before shipping and delivery

6. Excellent following-sale provider, Our wokers are all specialist and all can speak English.

seven. Well timed supply, We have many prolonged cooperation provider. source A single-End service

eight. High-tech CNC Equipment

nine. Impartial Engineering Office

ten.Types of surface area therapy—Zinc Plating, Powder Coating, Anodizing, Chrome Plate, RoHs .etc .

FAQ

1.Q:Are you a manufacturer or a buying and selling organization?

A:We are a professional producer with twenty years of business knowledge

two.Q:What about the lead time?

A: 2–3 days for sample 15–thirty times for mass creation. If urgent,we have inexperienced channel.

three.Q:Do you have any MOQ limit for conveyor belt purchase?

A: Reduced MOQ, 1pc for sample checking is accessible

four.Q: What are the positive aspects compared with other suppliers?

A: We have 6 manufacturing lines, a manufacturing base of 10300 square meters, an annual output of 900 million sq. meters, 8900 enterprises believe us, and we are hugely praised

5.Q: Do you have pre-sale support?

A: Of training course, we have 2 engineers at the identical time to serve you, can help you pick the most suited conveyor belt for you, you can also visit our production foundation, we welcome you really significantly

|

US $0.6-1.3 / Piece | |

10 Pieces (Min. Order) |

###

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Stainless Steel |

| Surface Treatment: | Oxygenation |

| Application: | Chemical Industry, Mining Transport, Automation Industry |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

Steel Timing Pulley

|

|

Warranty

|

1 year

|

|

Certification

|

ISO

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Farms, Construction works , Other, Textile Machinery

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

China

|

|

Brand Name

|

Annilte

|

|

Product name

|

Timing Belt Pulley

|

|

US $0.6-1.3 / Piece | |

10 Pieces (Min. Order) |

###

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Stainless Steel |

| Surface Treatment: | Oxygenation |

| Application: | Chemical Industry, Mining Transport, Automation Industry |

###

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

Steel Timing Pulley

|

|

Warranty

|

1 year

|

|

Certification

|

ISO

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Farms, Construction works , Other, Textile Machinery

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

China

|

|

Brand Name

|

Annilte

|

|

Product name

|

Timing Belt Pulley

|

What Is a Pulley?

The pulley is a wheel mounted on a shaft or axle. Its purpose is to support the movement of a cable that is taut. This cable transfers power to a shaft. However, there are certain safety precautions that you should follow when using a pulley. Read on to learn more! Listed below are common uses and their main parts. Listed below are some of the benefits of using a pulley.

Common uses of a pulley

A pulley is a common mechanical device used to increase the force needed to lift a heavy object. Most commonly, these devices are used in construction equipment. These machines use high-tension ropes to transfer heavy objects from one floor to another. Other common uses of a pulley include buckets and flagpoles. These devices are extremely useful in a wide range of applications. To learn more about the common uses of pulleys, keep reading.

A pulley is a wheel with grooves for holding rope. Its purpose is to change the direction and point at which a pulling force acts. It is usually used in sets to reduce the amount of force needed to lift a load, but the work involved is similar. Pulleys are also used in rock climbing devices. For many applications, a pulley is a vital part of construction.

The most common use of a pulley involves hoisting and lowering a flag. Other examples include clotheslines, bird feeders, and escalators. Pulleys are also commonly used on oil derricks. Many other common applications include hoisting and lowering garage doors. Pulley systems are also used in engines and cranes. For more information, check out our interactive pulley diagram!

Pulleys can also be used to lower total work required for a task. In many cases, a pulley will consist of two parts: the pulley hub and the shaft pulley. The hub clamps the shaft pulley, while the pulley itself is connected to the motor or other device. If you’re looking for a pulley, it’s important to learn how it works.

The most common uses for a pulley involve lifting heavy objects, and the mechanism used to lift them is known as a pulley. A pulley is an industrial device that uses two wheels to reduce the force needed to lift a weight. The pulley reduces this force by half by allowing the user to pull on the rope four times as far. The pulley also allows for a smaller lifting distance.

Main parts of a pulley

A pulley consists of the main element of a system. This is typically a cable, rope, belt, or chain. There are two basic types of pulleys – a Driver Pulley and a Follower Pulley. Pulleys are available in small and large sizes. The periphery part of the pulley is called the Face, and the protruding middle part is called the Crown. A pulley’s face can be round, rectangular, or even “V” shaped.

The first pulley was created by the Greek mathematician Archimedes in the third century BCE. These simple machines are made of a rope, an axle, and a wheel. The pulley’s end is attached to a person, object, or motor. These machines can be used in various tasks to lift heavy objects. The pulley is a great mechanical advantage for any lifter.

The ideal mechanical advantage of a pulley is defined by the number of rope segments that pull an object. The higher the number of loops on the rope, the higher the mechanical advantage. The greater the mechanical advantage, the less force is required to move the object. Likewise, the greater the distance the rope traverses, the higher the mechanical advantage of a pulley. There are several different types of pulley, depending on their combination of rope, wheel, and rope.

The basic components of a pulley are the face and hub, and the rope is threaded into the center of the pulley. The pulley is usually made of a rope and can be used to lift heavy weights. It can also be used to apply great force in any direction. Step pulleys have multiple faces, which are fixed in sequence. They can also increase the speed of the driven pulley.

A pulley is a simple machine consisting of a wheel, rope, or chain. These parts are crucial for making moving and lifting easier. Because they change the direction and magnitude of force, they can be a useful tool. Some pulleys even change direction. You can learn more about the pulley by downloading this resource today. The resources are designed to support the new 9-1 GCSEs in Design & Technology and Engineering.

Mechanical advantage

Pulleys have been used to move heavy objects for centuries. When two rope sections are used, the weight of a 100kg mass can be moved with only 500 newtons of force. Adding an extra pulley increases the mechanical advantage. If the pulley has two wheels, the distance between the rope sections and the wheel grooves is only half the distance, but the mechanical advantage still applies. Adding another pulley increases the mechanical advantage, but can be risky.

Mechanical advantage is the ratio of force used versus force applied. The calculations are made under the assumption that the ropes and weights do not elongate or lose energy due to friction. If the weights are very light, the mechanical advantage is greater than that in the real world. To calculate the mechanical advantage, the weight of the load to be lifted must be the same as the weight of the person using the pulley.

A single moveable pulley has a mechanical advantage of two. The weight passes around the pulley, and one end of the rope is attached to a fixed point. The pulling force is then applied to the other end of the rope. The distance the weight travels doubles, or halved, depending on the direction of the pulley. Adding a second pulley reduces the distance and the effort required to lift it.

There are several ways to calculate the mechanical advantage of a pulley system. Some methods are specific to certain types of systems, while others work for all systems. The T-Method is a good choice in many applications, as it calculates the units of tension for each rope segment. Once you have determined the input force, you need to determine the maximum force that will be applied to each component. A compound pulley, for example, will require 4 units of tension for each rope segment.

In simple terms, the effort is the amount of force needed to lift the load. This force is measured in newtons (N). A mechanical advantage is often presented without units. If the student does not have this unit, you may need to convert the units to newtons, since one kilogram is equal to 10 newtons. If you can’t figure out the units of effort, you can use the KWL chart provided by the teacher.

Safety precautions

There are a few safety precautions you should take when using a pulley. First, always check the SWL (safe working load) before attaching anything to the pulley. This indicates the maximum weight and angle the pulley can safely handle. Second, make sure that your work area is free from people and debris. Third, wear a hard hat to protect your head from blows and falling objects.

Another important consideration is anchoring. Although the pulley reduces the weight of an object, it is not enough to eliminate the weight. This is especially true if you are hoisting a heavy object, such as a motorcycle or lawnmower. It is important to ensure that the anchoring point can support the entire weight of the load. It is also important to follow proper anchoring procedures when using a pulley to lift a motorcycle or lawnmower.

In addition to the safety latch, you should use a tag line to control the suspended load. Remember that a chain pulley block is necessary for vertical lifting. You should also wear personal protective equipment (PPE) while using a pulley to avoid injuries. If your workplace does not have an PPE policy, you should consider implementing a similar policy. These safety guidelines are a good start.

If you are using a pulley to lift heavy objects, make sure to wear gloves. Those who are not familiar with rope-pulling will have an easier time demonstrating how it works. If you are using a rope-pulley system in a classroom, be sure to follow lab safety guidelines. Wear cloth gloves, clear the area, and do not jerk the rope. In addition, never allow yourself to be pulled into the rope by an unfamiliar person.

Another important safety precaution when using a pulley is to ensure that the anchor point for your system is adequate to support the weight of the object being lifted. Check with the manufacturer of the pulley to find out what its weight limit is, as some types of pulleys are designed to lift much heavier weights than others. It is important to follow all manufacturer’s instructions when using a pulley.

editor by czh 2022-12-20

China Aluminum Replacement Cam Gear Cam Pulleys manufacturer

Solution Description

Aluminum alternative cam equipment cam pulleys

Description:

We a company, primarily make all of the CNC components of bike which was used of superior precision maching equipment. So the goods had large good quality, and the cnc areas can adjust the fashion in accordance to customers’ specifications.

1.CNC Machined.

two.Material:aluminum alloy

three.We also can style as customer’s request or stick to customer’s blueprint to make it.

four.We welcome you to buy, we will give you a concessional rete.

five.We can bundle merchandise in accordance to your request.

Aluminum alternative cam equipment cam pulleys

| Substance | Aluminum, Steel,Zinc,Brass,Plastic. |

| Surface Treatment | Nickel plating, Zinc plating, Chrome plating, Anodizing, black coating, mill |

| Tolerance | +/-.01 mm |

| Inspection | Every single product at least 5 times of inspection processes |

| Package | plastic bag, Bubble bag, box, carton, wooden case, skin packing |

| Equipment | Quantity |

| CNC machining center | fourteen( include 4axis processing center) |

| CNC milling equipment | 2 |

| CNC lathe | 8 |

| slicing equipment | 4 |

| Three -COMERO | 1 |

| Welding device | four |

| Punch | two |

| Blister packaging machine | one |

| vibratory finishing equipment | two |

| Other equipment | twenty |

|

US $28 / Piece | |

20 Pieces (Min. Order) |

###

| Type: | Auto Fasteners |

|---|---|

| Material: | Aluminum |

| Colour: | Blue , Red , Yellow , Grey , Silvery , Black, Gree |

| Cam Pulleys Size: | You Need |

| Surface Treatment: | Anodizing , Zinc Plating , etc. |

| Material Science: | Aluminum , Brass, Copper , Nylon etc. |

###

| Customization: |

Available

|

|---|

###

| Material | Aluminum, Steel,Zinc,Brass,Plastic. |

| Surface Treatment | Nickel plating, Zinc plating, Chrome plating, Anodizing, black coating, mill |

| Tolerance | +/-0.01 mm |

| Inspection | Every single product at least 5 times of inspection processes |

| Package | plastic bag, Bubble bag, box, carton, wooden case, skin packing |

###

| Equipment | Quantity |

| CNC machining center | 14( contain 4axis processing center) |

| CNC milling machine | 2 |

| CNC lathe | 8 |

| cutting machine | 4 |

| Three -COMERO | 1 |

| Welding machine | 4 |

| Punch | 2 |

| Blister packaging machine | 1 |

| vibratory finishing machine | 2 |

| Other machine | 20 |

|

US $28 / Piece | |

20 Pieces (Min. Order) |

###

| Type: | Auto Fasteners |

|---|---|

| Material: | Aluminum |

| Colour: | Blue , Red , Yellow , Grey , Silvery , Black, Gree |

| Cam Pulleys Size: | You Need |

| Surface Treatment: | Anodizing , Zinc Plating , etc. |

| Material Science: | Aluminum , Brass, Copper , Nylon etc. |

###

| Customization: |

Available

|

|---|

###

| Material | Aluminum, Steel,Zinc,Brass,Plastic. |

| Surface Treatment | Nickel plating, Zinc plating, Chrome plating, Anodizing, black coating, mill |

| Tolerance | +/-0.01 mm |

| Inspection | Every single product at least 5 times of inspection processes |

| Package | plastic bag, Bubble bag, box, carton, wooden case, skin packing |

###

| Equipment | Quantity |

| CNC machining center | 14( contain 4axis processing center) |

| CNC milling machine | 2 |

| CNC lathe | 8 |

| cutting machine | 4 |

| Three -COMERO | 1 |

| Welding machine | 4 |

| Punch | 2 |

| Blister packaging machine | 1 |

| vibratory finishing machine | 2 |

| Other machine | 20 |

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations

There are several safety considerations to consider when using pulleys. The first is Secure Workload (SWL). This value is a general guideline for the maximum weight a pulley can safely handle. It varies according to the height and angle of the pulley. Besides SWL, there are some other factors to consider. Consider each one before deciding on the pulley that best suits your needs.

Another safety consideration is the weight of the load. Since the highs of the pulley are higher than the lows, it doubles in weight. The weight of the high point should not exceed 4 kN. The safety factor is calculated by multiplying the strength of the pulley by the weight of the load. Secondary COD has a safety factor of 10:1 and bulletproof primary anchors should be used with pulleys.

If using a chain hoist, you must be trained in the appropriate type of lifting. It is important not to hang on the top hooks of the structure, nor to overload or rig the hooks with multiple slings. You should also avoid corroded or damaged chains, as they can cause the crane to jam or overload. A worn chain can even cause the load to drop.

Components of a pulley system

Proper design of the pulley system can increase the life of the cables and pulleys. Larger diameter cables should be selected as they are more durable than smaller diameter cables. The cables should also be supported in the pulley grooves. The pulley must be designed to be compatible with the cable and its lubrication should be optimal. Proper lubrication of cables and pulleys will ensure maximum durability and longevity.

The first type of pulley is called a fast pulley. These pulleys are used for quick start and stop of the machine. These pulleys are usually mounted in pairs on the countershaft of the machine. One pulley is tightly mounted on the machine shaft, while the other pulley is fitted with a free-spinning mechanism. When the machine is running, the belt is mounted on the tensioner pulley, and when it is stopped, the belt slides on the independent pulley.

Composite pulley sets reduce the overall effort required by reducing the size of the pulley. These are usually attributed to Archimedes. Flat pulleys are often used in flat belt driven transmission systems. These are used in high-speed, low-power applications. Flat pulley idlers are also used on the back of traditional V-belts.

editor by czh 2022-11-29

China manufacturer & factory supplier for scooter in Taibei China, Taiwan Province of China sprocket roller chain sprocket double sprocket chain transmission parts gear With high quality best price & service

We’ve bui”EPG” manufacturer rotocultivator ploughshares in T.S. overall lines made in our manufacturing unit have been analyzed and appraised by the Ministry of Agriculture and have attained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. lt up our item variety to answer to the vastly diverse problems found in diverse industrial environments about the globe. From weighty business to precision producing, we operate with end-users in nearly every single business and have expert solutions which are confirmed to offer a distinctive efficiency advantage for your application.Our technicians and engineers have 23 several years of Experience in the Bearing Business.

Overview

Swift Information

- Relevant Industries:

-

Hotels, Garment Shops, Creating Content Outlets, Manufacturing Plant, Equipment Repair Stores, Meals & Beverage Manufacturing unit, Farms, Cafe, Home Use, Retail, Meals Store, Printing Shops, Vitality & Mining, Foodstuff & Beverage Retailers, Promoting Company, Development operates

- Materials:

-

Stainless Steel

- Normal:

-

ISO

- Location of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Item title:

-

roller chain sprocket

- Software:

-

Transmission Equipment

- Sort:

-

Common Chain Wheel

Provide Capacity

- Source Capability:

- a hundred thousand Piece/Parts for every Month

Packaging & Supply

- Packaging Specifics

- picket scenario

- Port

- Shanghai/ Ningbo Port

-

Guide Time

: -

Quantity(Containers) 1 – one >1 Est. Time(times) 1 To be negotiated

On the web Customization

Customer Assistance EPG is committed to providing world course consumer support, for equally recent and legacy products, putting you, our customer, at the heart of everything we do, we really are with you at every single turn.

Substantial High quality Industrial Chain Sprocket Casting Sprocket Standard Sprocket transimission parts

Product Description

|

Merchandise Name |

Chain Sprocket |

Our sprockets can be solid or fabricated to your needs

Bores are machined to H9 Tolerance, BS 4500 Part 1 (ISO R286).

Keyways are metric, both tapered or parallel to BS 4235 Component 1, 1972 (based mostly on ISO/R773 & R774).

Highlights:

Scenario conveyor chain for food sector, washing machines

Reversible procedure attainable

Special materials offered on ask for (bare minimum get quantities)

Sprockets are keywayed in pairs on centre line of the tooth gap with bosses facing, deep stop of tapered keyway on boss facet.

One setscrews are positioned above the important way. ASFI M100 PTO AdapterAs a precautionary evaluate, it is a good concept to purchase a PTO adapter to ensure compatibility with your certain tractor design.ny 2nd setscrew is positioned at ninety levels to the 1st.

Business Details

Trade Exhibits

Connected Merchandise

other sequence solution

| Precision Planetary gearbox | Robotic RV gearbox pace reducer |

| Custom made created Non-common Gearbox | UDL Collection Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Sequence Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Sequence Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Series Substantial Power Reducer |

| NMRV Series Worm Reducer | BKM Sequence Helical-hypoid Reducer |

| SLRC Collection Helical Reducer | SLSMR Collection Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Series Helical Reducer |

Packaging & Transport

Packing Information : Standard carton/Pallet/Common picket situation

Shipping and delivery Details : 15-thirty functioning times on payment

Get in touch with

China manufacturer & factory supplier for china in Seville Spain supplier Professional Machining Industrial High Precision Steel Spur Gear With high quality best price & service

Roller Chain Parts Every chain is related at the ends to form a full circle or chain loop by a grasp connecting hyperlink. Cotter plates or spring clips preserve the connecting link’s pins from doing work free.Obtaining accumulated valuable encounter in cooperating with overseas clients, a specialized provider of a full range of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

EPG Equipment is situated in XiHu Region HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou global airport.

Overview

Quick Particulars

- Applicable Industries:

-

Constructing Content Stores, Production Plant, Farms, Design works , Energy & Mining, Meals & Beverage Shops

- Certification:

-

ISO9001

Supply Ability

- Offer Capacity:

- 2000000 Piece/Parts per Month

Packaging & Supply

- Packaging Particulars

- 2. Personal Paper Box/Carton/Pallet

3. As the clients’ prerequisite”>1. Industrial Exporting Package deal with anti-tarnish paper/Carton/Pallet

two. Specific Paper Box/Carton/Pallet

3. As the clients’ requirement

- Port

- Qingdao/Shanghai/Tianjin/Guangzhou

On the web Customization

HangZhou At any time-Electrical power transmission Co. Ltd. One particular of department of Ever-Electrical power Team – the most significant China transmisssion supplier. With 1200 employee and precision products, we generate higher quality goods to United states of america and EU and other areas.

Specialist Machining Industrial High Precision Steel Spur Equipment

Product parameter

| Product name | Aluminum gears | |||

| Solution feather | OEM,customer layout | |||

| Merchandise parameters | High manganese metal/ large carbon steel/ alloy metal and so forth., | |||

| Application | Manufacturing, hefty industry, automotive, shipping, design, machinery etc., | |||

Solution present

More Merchandise

Business Data

Started in Could 1979, the calendar year when China began its open plan, we are a mentioned owned extensive organization combining “market & trading, technoloHow Can You Be Secure When Using PTO Shafts? First, make confident the shaft is shielded. This consists of the driveline protect that handles the put into action driveline, and the learn defend which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are typically mounted on bearings, so they require to be managed. always REPLACE the shield when it is broken or missing.Next, hold a secure length from it when in use. Keep other people absent, also. How considerably? A length of twice your peak is a excellent begin.Allow only these who definitely should be in the area to be there. Preserve all children absent!Always pay attention to what is occurring. Most PTO victims ended up caught by shock.If some thing goes improper — end the equipment get the PTO out of gear, quit the engine and established the brake. Place the keys in your pocket just before working on the equipment.When stopping the machinery for any explanation — end of work, lunch, repairs, or conversation — take the PTO out of gear, cease the engine and set the brake.Road planers, dredges, and other products demand energy from some type of motor in purchase to perform their designed perform. Without a electricity get off, it would be essential to incorporate a 2nd engine to provide the electrical power necessary to run hydraulic pumps and other driveline attached equipment.gy & investing”. In 2002, our firm altered from state-owned organization to personal owned firm.Backed up by sturdy financial power, innovative amenities & technologies, and huge production capability of several factories, Xinguang has been establishing swiftly in business since its basis set up long- expression and helpful partnership with many buyers from most regions of the planet.Now, our workers are much more than 60, in which half of them are engineers. Almost certainly what helps make us distinct from other buying and selling firms is that we have a distinctive employees of each busineRV025~RV150 Reliable Shaft Enter RV025~RV150 Characteristics: 1. High quality aluminum alloy equipment box, light-weight fat and not rust 2. 2 optional worm wheel materials: Tin (Stannum) bronze or aluminum bronze alloy 3. Standard components and quite flexible for shaft configurations and motor flange interface 4. Many optional mounting alternatives 5. Lower sound, Higher efficiency in heat dissipationssmen and knowledgeable mechanical engineers, who have been working in the industry for several years. This attribute of us acts an essential part in top quality management, price manage, and services performance.Bearings & electricity transmission parts are our main export goods. Our bearings, chains, sprockets, pulleys, tapered bushings, and shaft collars have been mass -exported to various nations around the world and areas this kind of as North The us, Europe, Africa, South The usa and Southeast Asia.Our high quality merchandise, prompt delivery, and competitive pricing have gained us a lot praise from the buyers. By the difficult perform of our personnel by means of thirty a long time, Xinguang has turn into one particular of the main exporters of bearings& power transmission components in China.

We welcome buyers from the whole globe to cooperate with us.

Speak to us

China supplier made in China – replacement parts – in Ribeirao Preto Brazil Factory CNC Machining Plastic Nylon Gear Rack with top quality

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Company Information&colon

HangZhou Engineering Plastics Industries Co&period&comma Ltd&comma is the professional manufacturer of engineering plastic products&periodWe are a free technical supplier&commawhich have advanced automated production equipment&commaand very familiar with property of all kinds of plastics material&period

White MC Nylon gear with be EPT self-lubrication

Mc nylon&comma means monomer casting nylon&comma is a kind of engineering plastics utilized in extensive industries&comma has been used almo EPT each and every industrial area&time period

The caprolactam monomer is fir EPT melted&comma and extra catalyst&comma then poured it within moulds at atmosphere pressure so as to form in distinct castings&comma this sort of as&colonRod&comma plate&comma tube&periodThe molecule weight of mc nylon can get to 70&comma 000-one hundred&comma 000&solmol&comma 3 occasions than pa6&solpa66&periodIts mechanical properties are considerably higher than EPT nylon components&comma this kind of as&colonPa6&solpa66&periodMc nylon plays a more and much more essential part in the content li EPT advisable by our country&time period

Main Characteristics MC Nylon Gear&colon

one&periodGood wear-resistance

two&periodGood corrosion-resistance

3&periodHigh self-lubrication

four&periodHigh vibration-absorption

five&periodHigh noise-absorption

The property of MC Nylon Equipment &colon

| Property | Merchandise No&interval | Unit | MC Nylon &lparNatural&rpar | Oil Nylon&plusCarbon &lparBlack&rpar | Oil Nylon &lparGreen&rpar | MC90 &lparBlue&rpar | MCNylon&plusMSO2&lparLight Black&rpar | |

| Mechanical Homes | one | Density | g&solcm3 | one&period15 | one&period15 | one&period135 | one&period15 | 1&period16 |

| 2 | Drinking water absorption &lpar23ºCin air&rpar | &percnt | one&period8-2&period0 | one&period8-2&period0 | 2 | two&period3 | 2&period4 | |

| 3 | Tensile energy | MPa | 89 | seventy five&period3 | 70 | 81 | 78 | |

| four | Tensile pressure at crack | &percnt | 29 | 22&period7 | twenty five | 35 | 25 | |

| five | Compressive stress &lparat 2&percntnominal pressure&rpar | MPa | fifty one | fifty one | forty three | forty seven | 49 | |

| six | Charpy effect strength &lparunnotched&rpar | KJ&solm two | No brak | No crack | &geq50 | No BK | No break | |

| 7 | Charpy influence toughness &lparnotched&rpar | KJ&solm 2 | &geq5&period7 | &geq6&period4 | four | three&period5 | three&period5 | |

| eight | Tensile modulus of elasticity | MPa | 3190 | 3130 | 3000 | 3200 | 3300 | |

| 9 | Ball indentation hardness | N&solmm two | 164 | a hundred and fifty | 145 | one hundred sixty | 160 | |

| 10 | Rockwell hardness | – | M88 | M87 | M82 | M85 | M84 | |

Software of MC Nylon Equipment&colon

1&periodChemical Engineering

2&periodElectric&solElectronic industry

3&periodAuto industry

4&periodPacking machine

5&periodEngineering machine

6&periodPharmaceutical&solequipment industry

Our Service&colon

one&period Rich industry experience since 1988&time period

two&period Wide arrange product line&comma including plastics sheet&solrod&solparts&solaccessories&colon MC NYLON&comma OIL NYLON&comma POM&comma UHMW-PE&comma PU&comma PETP&comma PC&comma PTFE&comma PVDF&comma PPS&comma PEEK&comma PAI&comma PI&comma PBI ect&period

3&period Manufacture&comma design and processing service as per your demand&period

Production Flow&colon

Product technology&colon

CNC machine&commaExtrusion&commaInjection&commaect&time period

Processing Equipment &colon

CNC machining center&commaCNC lathes&commaMilling&commaInjection Molding Machine&commaExtruder&commaMoulding press

Packaging &Shipping&colon

Packing in plastics bags&commawooden case&commapallet&commacontainer&commaect&period

Certification&colon

Certification&colonISO&commaSGS&commaFDA&commaRoHS&commaTest report&commaect&interval

FAQ&colon

one&periodA&colon What’s the size of plastics sheet&quest

B&colonNylon sheet&colonThickness&astWidth&astLength&colon20-a hundred&ast1000&ast2000mm

UHMW-PE sheet&colonThickness&astWidth&astLength&colon20-a hundred&ast1000&ast2000mm&semi20-100&ast1250&ast3130mm&semi 20-100&ast1250&ast4250mm

POM sheet&colonWidth&astLength&colon1000&ast2000mm

2&period A&colonCan we purchase a small part of plastics sheet&quest

B&colon Yes&commayou can&comma if we have the size you require in stock&interval

three&period A&colonWhat color of plastics sheet&quest

B&colon Nylon sheet&colon Natural&commablack&commablue&commaor according to client’s requiremnet&interval

UHMW-PE sheet&colon White&commablack&commagreen &commabule&commayellow&commaor according to client’s requirement&period

White&commablack

4&period A&colonCan you manufacture the plastics products as per drawing&quest

B&colon Yes&commawe can&period

five&periodA&colon What the precision of plastic products according to drawing&quest

B&colon Different machine with different precision&commait usually around 0&period05-&period1mm

6&periodA&colon What the technologies in producing plastics parts&quest

B&colon Different products with different technologies&commasuch as CNC machine&commaExtrusion&commaInjection

seven&colon A&colonWhat kinds of processing machine do you have&quest

B&colon CNC machining center&commaCNC lathes&commaMilling&commaInjection Molding Machine&commaExtruder&commaMoulding press

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 distinct branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original products manufacturer’s (OEM) component figures or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our company and the detailed substitute parts contained herein are not sponsored, accepted, or produced by the OEM.

42mm made in China – replacement parts – in Hannover Germany BLDC Gear Reducer Motor with Planetary Gearbox with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 distinct branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product Description

42mm bldc equipment reducer motor with planetary gearbox Specifications:

Note : It’s ju EPT the standard specialized information for you reference, The specification this sort of as voltage, pace, torque, shaft can personalized.

More Information:

Rated Voltage: 24V

No Load Speed: 17-1200rpm

Load Torque: .2-4N.m

Output Energy: 1-20W

Motor Size: 42*42mm

Gearbox Size: 36mm dia.

Shaft Diameter: 8mm

Shaft Type: Carbon Metal Shaft, Accept Customized

Associated Products

Firm Profile

HangZhou Leison Motor Co. Ltd is a manufacturer and exporter of various of motors with in excess of ten years expertise.

Our solution ranges incorporate:

one) DC Brush motor: 6-130mm diameter, .01-1000W output electricity

two) DC Spur Gear Motor: twelve-110mm diameter, .1-300W output power

three) DC Planeary Equipment Motor: ten-82mm diameter, .1-100W output power

4) Brushless DC Motor: 28-110mm, 5-1500W output power

five) Stepper Motor: NEMA 08 to NEMA forty three, Can with gearbox and lead screw

six) Servo Motor: 42mm to 130mm diameter, 50-4000w

7) AC Gear Motor: 49 to 100mm diameter, 6-a hundred and forty output power

Production Tools

Certifications

Consumer Go to and Fair

FAQ

Q: What is actually your main goods?

A:We currently produce Brushed Dc Motors, Brushed Dc gear Motors, Planetary Dc Equipment Motors, Brushless Dc Motors, Stepper motors and Ac Motors etc. You can verify the specs for previously mentioned motors on our web site and you can e mail us to advise needed motors for every your specification way too.

Q:How to pick a suitable motor?

A:If you have motor images or drawings to show us, or you have comprehensive specs like voltage, speed, torque, motor dimension, working manner of the motor, necessary daily life time and noise amount and many others, remember to do not be reluctant to permit us know, then we can advocate appropriate motor for each your reque EPT accordingly.

Q: Do you have customized service for your standard motors?

A:Of course, we can customize per your reque EPT for the voltage, pace, torque and shaft measurement/shape. If you need to have added wires/cables soldered on the terminal or want to add connectors, or capacitors or EMC we can make it too.

Q:Do you have person layout service for motors?

A:Sure, we would like to design motors separately for our clients, but it could require some mould demand and layout charge.

Q:Can I have samples for screening very first?

A:Sure, absolutely you can. After verified the required motor specs, we will estimate and supply a proforma invoice for samples, after we get the payment, we will get a PASS from our account division to commence samples accordingly.

Q:How do you make certain motor top quality?

A:We have our own inspection processes: for incoming supplies, we have signed sample and drawing to make positive certified incoming resources for production approach, we have tour inspection in the approach and closing inspection to make positive qualified merchandise prior to delivery.

Q:What’s your guide time?

A:Generally talking, our standard standard item will want twenty five-30days, a bit for a longer time for personalized products. But we are really flexible on the guide time, it will depends on the particular orders

Q:What’s your payment term?

A:For all our new consumers, we will need to have 40% deposite, sixty% compensated just before shipment.

Q:When will you reply after obtained my inquiries?

A:We will response inside of 24 several hours once get your inquires.

Q:How can I tru EPT you to make positive my income is secure?

A:We are accredited by the third social gathering SGS and we have exported to over eighty five countries up to June.2017. You can check out our reputation with our recent consumers in your place (if our buyers do not brain), or you can order by way of alibaba to get trade assurance from alibaba to make sure your funds is secure.

Q:What is actually the bare minimum order quantity?

A:Our least purchase quantity is dependent on diverse motor models, you should e-mail us to check. Also, we normally do not acknowledge personalized use motor orders.

Q:What is your delivery strategy for motors?

A:For samples and offers considerably less than 100kg, we generally sugge EPT convey delivery For weighty offers, we typically sugge EPT air delivery or sea shipping. But it all relies upon on our customers’ needs.

Q:What certifications do you have?

A:We at present have CE and RO EPT certifications.

Q:Can you send me your price listing?

A:Because we have hundreds of various products, and cost may differ for each distinct specs, we are not able to offer a price checklist. But we can quote inside 24 hrs after got your inquirues to make confident you can get the cost in time.

Q:Can I visit your company?

A:Yes, welcome to check out our firm, but make sure you allow us know at lea EPT two weeks in progress to assist us make positive no EPT conferences during the day you visit us.

Many thanks!

Contact Us

HangZhou Leison Motor Co.,Ltd

Get in touch with Individual: Celia Chen

Tel: +86-571-27835797

Any email or trademanager inquires will be replied inside 24 several hours.

Typical samples can be supply very rapidly(in ten times)

Custom-made services for sort of motor accoring to your need

Specialist Tchnical assist and Right after-sale services

Sourcing motor elements like gears, encoders, cables, connectors and so on

The use of unique equipment manufacturer’s (OEM) component numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our organization and the listed substitution areas contained herein are not sponsored, accredited, or created by the OEM.

China price made in China – replacement parts – in Manchester United Kingdom Manufactory M1 M2 M3 M4 Customized Metal Spur Gear with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For far more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Solution Info

Xihu (We EPT Lake) Dis.g Large Precision Personalized Spur Gear

Gear transmission refers to the gadget that transmits motion and energy from the equipment pair. It is the mo EPT extensively utilized mechanical transmission method in present day equipment. Its transmission is a lot more precise, substantial efficiency, compact structure, dependable operation and long provider lifestyle.Our gears can be heat taken care of, hardened, oil immersed in accordance to buyer requirements.The equipment is broadly utilised in sector, automobile, power equipment, motor, bicycle, electrombile.

We can make customers’ satisfactory products in accordance to the samples or drawings presented by consumers. For the completion of a item, we also need to have to know its substance, warmth treatment method needs and area treatment needs. We are a manufacturing unit with forty several years of producing knowledge, welcome to check with.

The benefit of our gear

1 Vast selection of relevant peripheral speeds and powers.

two The transmission ratio is precise, stable and productive.

three Reputable performance and long support existence.

HangZhou Xihu (We EPT Lake) Dis.g EPT EPT Co., Ltd. is a specialized supplier of a entire variety of motor shafts, gears, Flanges(Couplings), gear racks, sprockets, pulley, machined parts and so on.

Due to our sincerity in offering be EPT services to our consumers, understanding of your requirements and overriding sense of duty toward filling buying demands, we have acquired the tru EPT of consumers globally. Possessing amassed precious expertise in cooperating with international customers, our goods are offering effectively in the American, European, South American and Asian marketplaces.Our items are made by contemporary computerized equipment and equipment. Meanwhile, our merchandise are made in accordance to large top quality requirements, and complying with the worldwide innovative standard conditions.

With a lot of years’ knowledge in this line, we will be trusted by our advantages in competitive cost, one-time delivery, prompt response, on-hand engineering assistance and excellent after-income providers.

Furthermore, we also can design and style and make non-normal merchandise to satisfy customers’ particular requirements. High quality and credit are the bases that make a corporation alive. We will provide be EPT companies and higher quality goods with all sincerity. If you require any information or samples, you should make contact with us and you will have our shortly reply.

FAQ

one)Are you investing business or company?

We are manufacturing unit.

2)How can I customise my products?

Connect your drawing with specifics(surface area treatment method,materials,quantity and unique needs and many others.)

three)How extended can I get the quotation?

We will give you the quotation in forty eight several hours(contemplating the time distinction)

4)How extended will you produce the parts?

Generally it is 5-10 times if the goods are in inventory. Or it is 15-25 times if the goods are not in stock, it’s according to amount.

five)Do you supply samples? Is it free of charge or further?

Indeed, we could provide the sample, the samples and delivery fees require to be borne by the shopper.

6)What is your phrases of payment?

Payment≤1000 USD, one hundred% in advance. Payment≥1000 USD, thirty% T/T in progress, harmony just before shipment. If you have any queries, remember to will not be reluctant to get in touch with us.

7)What if the items we acquired are not very good?

Speak to us with out hesitation, our unique right after-sales services will consider the accountability.

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 various branches. For much more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of authentic equipment manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our company and the outlined substitute areas contained herein are not sponsored, accredited, or produced by the OEM.