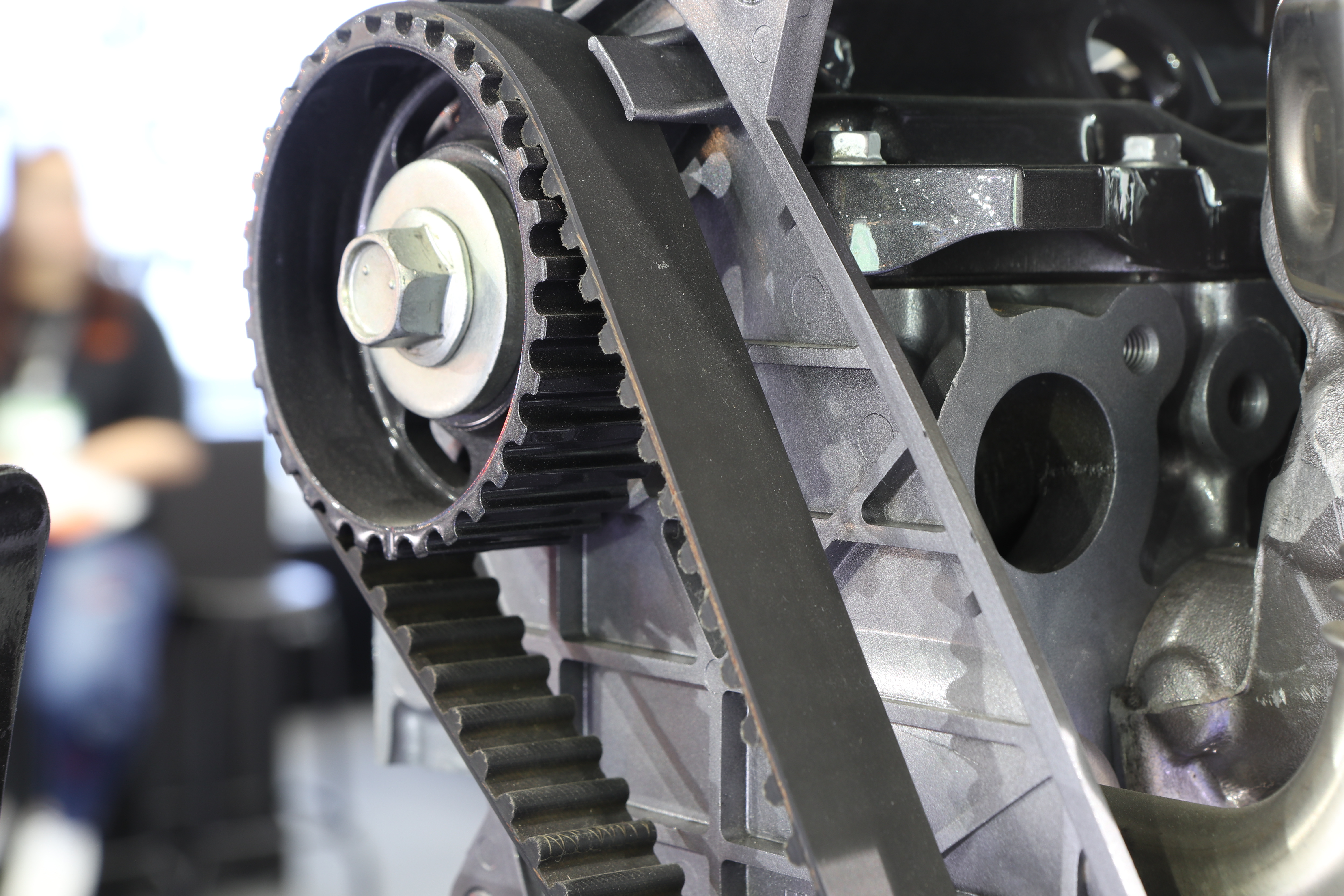

Product Description

Company Information

Founded in 1984, CZPT covers 45,

Company Name: HangZhou CZPT synchronous belt co., ltd

Add: Xihu (West Lake) Dis.n Town CIci City HangZhou ZHangZhoug China(Mainland)

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Heat-Resistant, Skid-Resistance, Wear-Resistant, High Temperature-Resistance |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the various mounting options and installations for V-belt tensioners in different settings?

Mounting options and installations for V-belt tensioners can vary depending on the specific application and setting. Different configurations are available to accommodate diverse space constraints, accessibility requirements, and tensioning force adjustments. Here’s a detailed description of the various mounting options and installations for V-belt tensioners:

- Fixed Mounting:

- Adjustable Mounting:

- Spring-Loaded Mounting:

- Separate Tensioner Assembly:

- Multi-Tensioner Systems:

In a fixed mounting configuration, the tensioner is permanently attached to a fixed point, such as a machine frame or structure. This type of installation is commonly used in applications where the belt tension is set at a specific value and does not require frequent adjustment. Fixed mounting provides stability and ensures that the tensioner remains in a fixed position, maintaining consistent tension over time. It is suitable for applications where space is limited and where the tensioning force does not need to be frequently modified.

Adjustable mounting configurations allow for easy tension adjustment of the V-belt. These tensioners feature a mechanism that enables the adjustment of the tensioning force by changing the position of the tensioner relative to the belt and pulleys. Common adjustable tensioners include those with slotted mounting holes or adjustable arms. This type of installation is suitable for applications where the tensioning force needs to be periodically adjusted to maintain optimal belt performance. Adjustable mounting provides flexibility and allows for fine-tuning the tension based on changing operating conditions or belt wear.

Spring-loaded tensioners incorporate a spring mechanism to automatically maintain the desired tension in the V-belt system. These tensioners feature a spring that applies a constant force on the belt, compensating for belt elongation and maintaining proper tension. Spring-loaded tensioners are commonly used in applications where there are fluctuations in load or thermal expansion/contraction of the belt. The spring mechanism ensures continuous tension adjustment, reducing the need for manual intervention and providing consistent tension across varying operating conditions.

In some cases, a separate tensioner assembly is used instead of mounting the tensioner directly to the machine frame or structure. A separate tensioner assembly consists of a bracket or support arm that is attached to the machine or structure, and the tensioner itself is mounted on the bracket or arm. This configuration allows for flexibility in positioning the tensioner and provides ease of installation and maintenance. It is particularly useful in applications where space constraints or accessibility limitations make direct mounting challenging.

In certain applications, multiple tensioners may be used within a V-belt system to ensure proper tension distribution and alignment. Multi-tensioner systems utilize a combination of tensioner types and mounting configurations to achieve optimal belt tensioning across multiple belts and pulleys. This configuration is commonly employed in complex drive systems with multiple belts or long-span belt setups. By using multiple tensioners strategically positioned along the belt path, consistent tension can be maintained, minimizing belt slippage, and maximizing power transmission efficiency.

When selecting the appropriate mounting option and installation for a V-belt tensioner, it’s important to consider factors such as space constraints, tensioning force requirements, accessibility for maintenance, and the specific needs of the application. Manufacturers typically provide guidelines and recommendations for the suitable mounting options and installations for their tensioner products. Following these guidelines, along with considering the specific requirements of the V-belt system, will help ensure the proper integration and effective operation of the tensioner within the application.

What is the impact of proper tensioning on the lifespan and reliability of V-belts?

Proper tensioning plays a crucial role in the lifespan and reliability of V-belts. Maintaining the correct tension level in V-belts is essential for their optimal performance and longevity. Here’s a detailed explanation of the impact of proper tensioning on V-belts:

- Preventing Slippage:

- Reducing Wear and Stretching:

- Preventing Belt Misalignment:

- Enhancing Load-Carrying Capacity:

- Improving System Efficiency:

Proper tensioning ensures that V-belts have sufficient grip on the pulleys. When V-belts are under-tensioned, they can slip on the pulleys, leading to inefficient power transmission and reduced belt lifespan. On the other hand, over-tensioning can put excessive stress on the belts and pulleys, causing premature wear and failure. Proper tensioning prevents slippage and maintains the necessary friction between the V-belts and the pulleys for reliable power transfer.

Correct tensioning helps minimize wear and stretching of V-belts. When belts are under-tensioned, they may experience excessive bending and flexing, leading to accelerated wear and elongation. Over-tensioning can cause excessive strain on the belts, resulting in stretching, fatigue, and reduced belt life. Optimal tensioning minimizes these issues, allowing V-belts to operate within their designed parameters and reducing the risk of premature wear and failure.

Proper tensioning helps maintain proper belt alignment. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment can lead to uneven belt wear, increased friction, and belt damage. Optimal tensioning ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving overall belt reliability.

Correct tensioning maximizes the load-carrying capacity of V-belts. When V-belts are properly tensioned, they can transmit higher levels of torque and power without slipping or excessive stress. This allows V-belts to handle the intended loads and operate efficiently under demanding conditions. Improper tensioning can compromise the load-carrying capacity of V-belts, leading to reduced performance, increased wear, and potential system failures.

Proper tensioning contributes to the overall efficiency of V-belt-driven systems. When V-belts are correctly tensioned, power transfer is optimized, and energy losses due to slippage or excessive friction are minimized. This results in improved system efficiency and reduced energy consumption. Optimal tensioning helps maintain the system’s performance, ensuring reliable operation and reducing the risk of downtime and costly repairs.

In summary, proper tensioning significantly impacts the lifespan and reliability of V-belts. It prevents slippage, reduces wear and stretching, maintains belt alignment, enhances load-carrying capacity, and improves system efficiency. Manufacturers, maintenance professionals, and operators should follow recommended tensioning guidelines and regularly inspect and adjust the tension of V-belts to ensure optimal performance, extend belt life, and minimize the risk of belt failure.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2023-11-30