Product Description

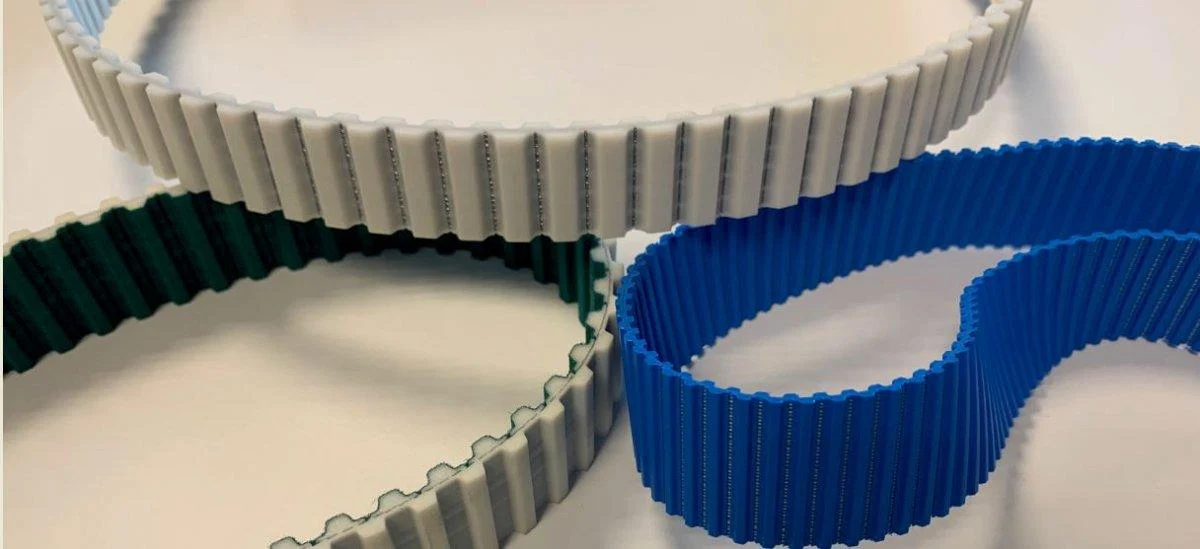

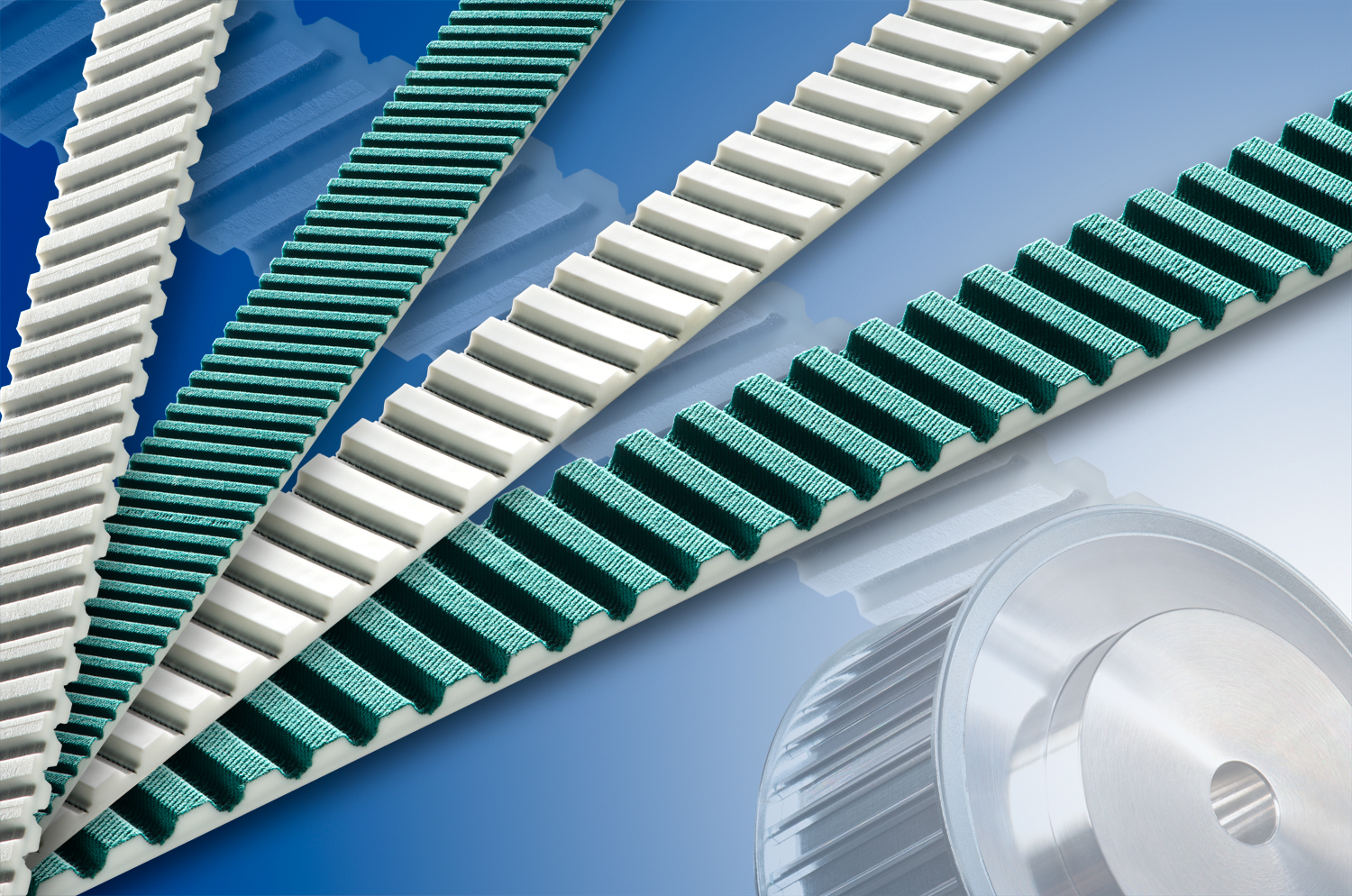

L XL MXL Timing Belt

1. LOW noises, NO slippage

2. HIGH transmission power

3. Wear Out Resistance

Industrial Rubber Timing Belt

MXL, XL, L, H, XH, XXH, HTD, T2.5, T5, T10, T20, AT5, AT10, AT20, 2M, 3M, 5M, 8M, 14M, 20M, S2M, S3M, S4.5M, S5M, S8M, S14M, RP2M, RP3M, RP5M, RP8M, RP14M

Open Belts

1. Open Ended Timing belt—-infinite long or joined endless type.

2. Strengthen cord is stainless steel, and Kevlar for your reference.

3. Adding green fabric on tooth for all sizes

4. All sizes can be jointed into endless belt.

Mechanism Property

– Stable Dimension

– Low Pull Force

– Small Noise

– Wear Out Resistance

– No need to maintain

– Excellent Elasticity

– Precise Line

– Max linear Speed can reach 80M/sec.

Chemical Property

– Anti Aging

– Anti Hydrolyze

– Anti UVA,

– Anti-Ozone

– Operating Temperature: -30° C~+80° C The Max. Degree within short time can up to +110° C

– Anti-oil and anti-ester

– Anti acid, alkaline resistance

– Combined with other thermoplastic materials

Our timing belts are composed of closed round rubber, with teeth and attached belt or pulley. When working, teeth and trough are in harmony and 1 movement will cause transmission of teeth, chain, and belt. We can produce most Korean and Japanese car timing belts, as well as European timing belts. We use high quality raw materials including Neoprene rubber, glass fiber cord, nylon cloth imported from the UK and Japan.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | PU Rubber |

|---|---|

| Transport Package: | Standard Sea Worthy Package |

| Specification: | iso |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications?

V-belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of V-belts in various applications. By maintaining proper belt tension, mitigating belt slippage, reducing wear, and minimizing the risk of belt failure, tensioners contribute to improved efficiency and extended belt life. Here’s a detailed explanation of how V-belt tensioners enhance the overall efficiency and lifespan of V-belts:

- Optimal Belt Tension:

- Reduced Belt Slippage:

- Wear Reduction:

- Vibration and Noise Damping:

- Prevention of Belt Failure:

V-belts operate most efficiently when they are running at the correct tension. Over-tensioned or under-tensioned belts can lead to problems such as excessive heat generation, increased wear, and reduced power transmission. V-belt tensioners ensure that the belts are properly tensioned by applying the right amount of force to maintain the desired tension level. This optimizes the power transfer efficiency and minimizes energy losses, resulting in improved overall system efficiency.

Proper tensioning provided by V-belt tensioners helps to minimize belt slippage, which is a common issue in V-belt drive systems. Belt slippage occurs when the belt slips on the pulleys, leading to a loss of power transmission efficiency. Tensioners maintain the necessary tension in the belt, ensuring a positive grip between the belt and the pulleys. By reducing slippage, tensioners help maximize power transfer, improve system efficiency, and prevent premature belt wear due to excessive slipping.

V-belt tensioners help reduce wear on the belts by ensuring proper alignment and tension. Misaligned or poorly tensioned belts can experience increased wear, resulting in premature belt failure. Tensioners keep the belts aligned and tensioned correctly, minimizing lateral movement and excessive belt wear. By reducing wear, tensioners contribute to the extended lifespan of the belts and reduce the need for frequent belt replacements, resulting in cost savings for the application.

V-belt tensioners can also help dampen vibrations and reduce noise in V-belt drive systems. Vibration and noise can occur due to belt oscillation or irregular belt-pulley contact. Tensioners stabilize the belt tension, reducing belt vibrations and associated noise. This not only improves the overall system performance but also enhances the working environment by reducing noise levels.

By maintaining optimal tension and reducing wear, V-belt tensioners help prevent belt failure. Belt failure can result in unexpected downtime, increased maintenance costs, and productivity losses. Tensioners ensure that the belts are properly tensioned and aligned, reducing the risk of belt fatigue, cracking, or premature breakage. This enhances the overall reliability and longevity of the belts, allowing for uninterrupted operation and improved application performance.

In summary, V-belt tensioners enhance the overall efficiency and lifespan of V-belts in various applications by maintaining optimal tension, reducing belt slippage, minimizing wear, damping vibrations and noise, and preventing belt failure. These benefits result in improved power transmission efficiency, extended belt life, reduced maintenance requirements, and enhanced system reliability. By incorporating well-designed and properly adjusted tensioners, applications can optimize the performance and longevity of V-belts, leading to increased productivity and cost savings.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

Can you provide examples of products or machinery that rely on V-belt tensioners for efficient operation?

V-belt tensioners play a critical role in ensuring efficient operation in various products and machinery across different industries. Here are some examples of products and machinery that rely on V-belt tensioners:

- Automotive Engines:

- Industrial Machinery:

- HVAC Systems:

- Power Generation Equipment:

- Agricultural Machinery:

- Woodworking Machinery:

In automotive engines, V-belt tensioners are essential for the proper functioning of various components. Examples include the alternator, water pump, power steering pump, air conditioning compressor, and superchargers. V-belt tensioners ensure optimal tension in the belts, preventing slippage and ensuring efficient power transfer to these components.

A wide range of industrial machinery relies on V-belt tensioners for efficient operation. This includes conveyor systems, pumps, compressors, fans, blowers, and generators used in manufacturing plants, mining operations, construction sites, and material handling facilities. V-belt tensioners help maintain proper tension, preventing belt slippage and ensuring reliable power transmission.

Heating, ventilation, and air conditioning (HVAC) systems commonly incorporate V-belt tensioners. These tensioners are used in HVAC fans, blowers, and pumps, which are critical components of climate control systems in buildings and industrial facilities. Proper tensioning of V-belts with tensioners ensures efficient operation and optimal performance of the HVAC equipment.

V-belt tensioners are vital in power generation equipment such as generators and turbines. These tensioners help maintain the proper tension in the belts, ensuring efficient power transfer from the prime mover to the generator or turbine. Reliable tensioning is crucial for the optimal performance and operation of power generation systems.

Agricultural machinery heavily relies on V-belt tensioners. Tractors, combines, and various agricultural implements use V-belts to transfer power to components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners ensure proper tensioning, preventing slippage and ensuring efficient operation in demanding agricultural environments.

Woodworking machinery, such as saws, planers, and sanders, often utilize V-belt tensioners. These tensioners help maintain the proper tension in the V-belts that drive the cutting tools and other components of the woodworking equipment. Efficient tensioning ensures precise and reliable operation in woodworking applications.

These are just a few examples of the wide range of products and machinery that rely on V-belt tensioners for efficient operation. V-belt tensioners are utilized in various other industries and applications, including marine propulsion systems, construction equipment, mining machinery, and more. The specific use of V-belt tensioners depends on the requirements of the application, ensuring reliable power transmission, extended belt life, and optimal performance.

editor by CX 2023-12-27