Product Description

Product Description

Raw materials

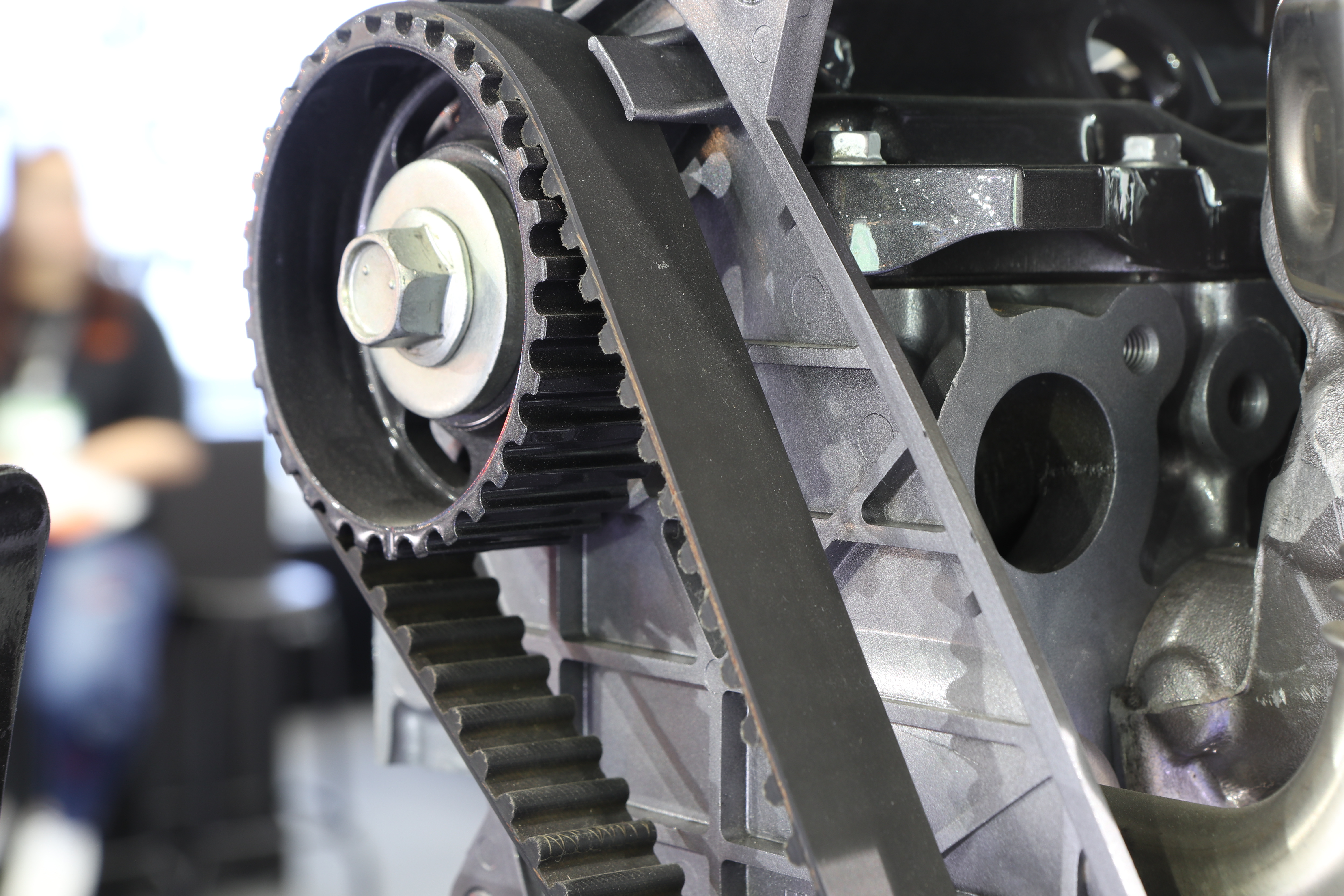

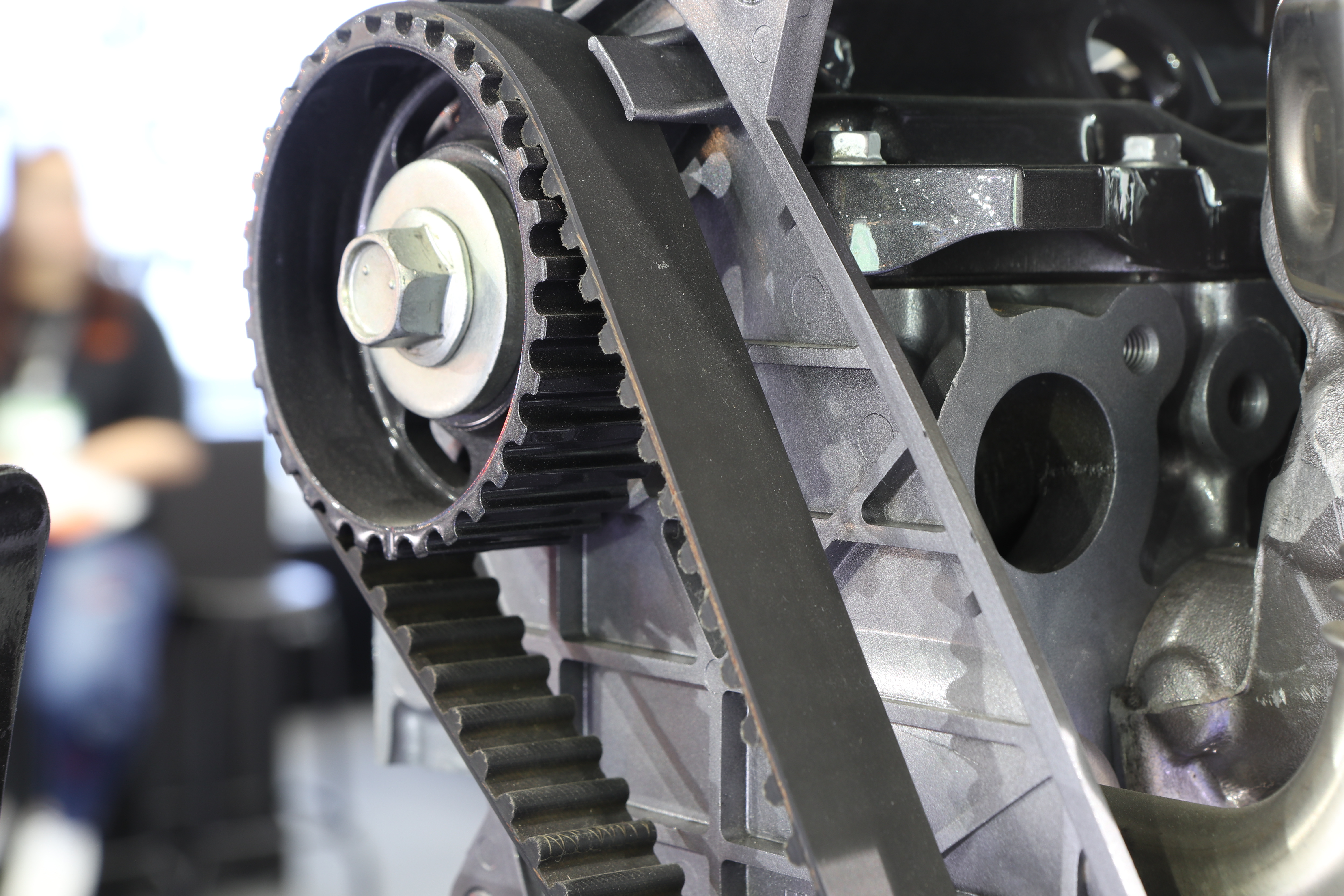

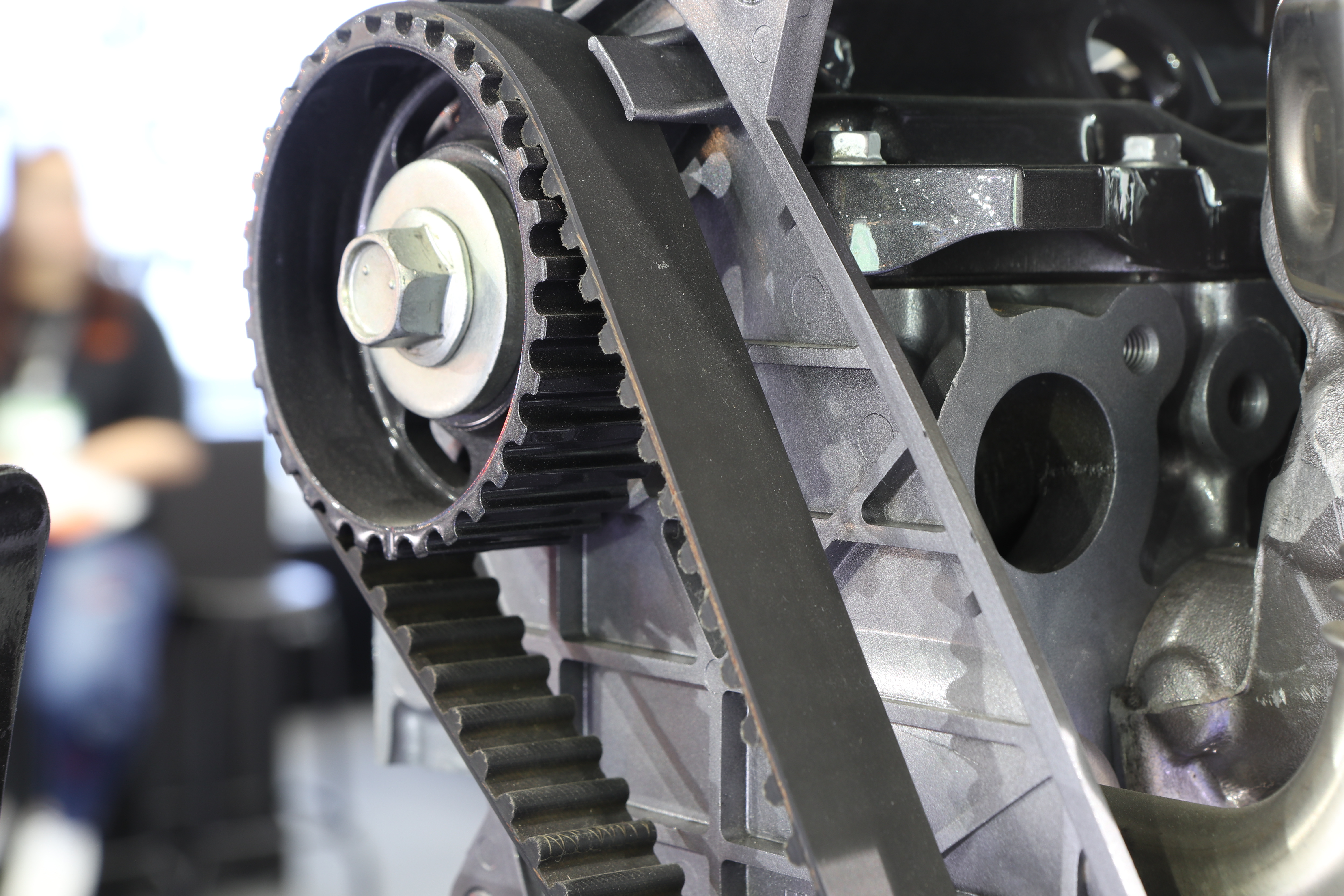

Belt: High-quality neoprene (CR)as the main raw materials( imported from Japan)

Skeleton materials: Glass Fiber(imported from Janpan)

Tooth surface: Nylon 66 high

Characteristics

strange anti-cracking properties,

ozone excellent performance,

anti-aging,

heat resistance,

oil resistance,

abrasion-resistant

Features:

With synchronous belt drive is the use of tooth and tooth meshing with the impetus to pass a new type of transmission mode. With accurate synchronous transmission function, do not need lubrication and no slip, no pollution, less noise, transmission efficiency of 0.98, the speed ratio range up to 1: 10, allowing, wire speed up to 50 m / s, the transmission rate from several hundred watts to the hundreds of kilowatts, suitable for multi-axis drive. Neoprene synchronous belt widely used in the textile, automobile, chemical fiber, tobacco, paper, printing, chemical mechanical equipment; In recent years, mining and metallurgy, iron and steel machinery, medical equipment demand is growing.

| T type Industrial Timing Belt |

||||

| Type | Pitch Pb (mm) |

Tooth height ht (mm) |

Belt thickness hs (mm) |

Angle β ° |

| MXL | 2.032 | 0.51 | 1.14 | 40 |

| XL | 5.080 | 1.27 | 2.30 | 50 |

| L | 9.525 | 1.91 | 3.60 | 40 |

| H | 12.70 | 2.29 | 4.30 | 40 |

| XH | 22.225 | 6.35 | 11.20 | 40 |

| XXH | 31.750 | 9.53 | 15.70 | 40 |

| T2.5 | 2.5 | 0.7 | 1.30 | 40 |

| T5 | 5 | 1.20 | 2.20 | 40 |

| T10 | 10 | 2.50 | 4.50 | 40 |

| T20 | 20 | 5.00 | 8.00 | 40 |

| AT5 | 5 | 1.20 | 2.70 | 50 |

| AT10 | 10 | 2.50 | 5.00 | 50 |

| AT20 | 20 | 5.00 | 8.00 | 50 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Auto Belt |

|---|---|

| Material: | Rubber |

| Certification: | ISO, DIN, JIS |

| Automatic: | Automatic |

| Standard: | Standard |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery?

Using V-belt tensioners in machinery offers several benefits in preventing slippage and optimizing power transmission. By maintaining proper belt tension, minimizing belt slippage, and ensuring consistent power transfer, tensioners contribute to improved efficiency, reduced energy losses, and enhanced overall performance. Here’s a detailed explanation of the benefits of using V-belt tensioners:

- Prevention of Belt Slippage:

- Optimized Power Transmission:

- Improved Efficiency:

- Reduced Wear and Maintenance:

- Enhanced System Reliability:

V-belt tensioners play a critical role in preventing belt slippage in machinery. Belt slippage occurs when the belt slips on the pulleys, resulting in a loss of power transmission efficiency and decreased performance. Tensioners apply the appropriate tension to the V-belt, ensuring a positive grip between the belt and the pulleys. This minimizes or eliminates slippage, allowing for efficient power transfer from the driving pulley to the driven pulley.

Proper tensioning provided by V-belt tensioners optimizes power transmission in machinery. When the V-belt is properly tensioned, it maintains a consistent contact area with the pulleys, maximizing the frictional grip. This efficient power transfer ensures that the input power from the driving pulley is effectively transmitted to the driven pulley, minimizing energy losses and maximizing the overall system efficiency.

By preventing slippage and ensuring optimal power transmission, V-belt tensioners contribute to improved efficiency in machinery. Slippage leads to energy losses, as power is wasted in overcoming the slipping motion instead of being transferred to the driven components. Tensioners maintain the necessary tension in the V-belt, reducing slippage and maximizing power transfer efficiency. This results in improved overall system efficiency, reduced energy consumption, and cost savings over time.

V-belt tensioners help reduce wear on the V-belts and associated components, leading to reduced maintenance requirements. Proper tensioning minimizes belt movement and excessive wear, extending the lifespan of the belts. By preventing slippage, tensioners also reduce the risk of belt damage, such as excessive heat generation or premature wear due to friction. This results in longer belt life, fewer replacements, and reduced maintenance costs for the machinery.

Using V-belt tensioners enhances the reliability of machinery by ensuring consistent power transmission. When the V-belts are properly tensioned, the risk of unexpected belt slippage or failure is significantly reduced. Reliable power transmission minimizes downtime, production interruptions, and the associated costs. Tensioners play a crucial role in maintaining the required tension in the belts, contributing to the overall reliability and uninterrupted operation of the machinery.

In summary, the benefits of using V-belt tensioners in preventing slippage and optimizing power transmission in machinery include the prevention of belt slippage, optimized power transfer efficiency, improved overall system efficiency, reduced wear and maintenance, and enhanced system reliability. By properly tensioning the V-belts, tensioners ensure efficient power transmission, reduce energy losses, and extend the lifespan of the belts, resulting in improved performance and cost savings for machinery applications.

What is the impact of proper tensioning on the lifespan and reliability of V-belts?

Proper tensioning plays a crucial role in the lifespan and reliability of V-belts. Maintaining the correct tension level in V-belts is essential for their optimal performance and longevity. Here’s a detailed explanation of the impact of proper tensioning on V-belts:

- Preventing Slippage:

- Reducing Wear and Stretching:

- Preventing Belt Misalignment:

- Enhancing Load-Carrying Capacity:

- Improving System Efficiency:

Proper tensioning ensures that V-belts have sufficient grip on the pulleys. When V-belts are under-tensioned, they can slip on the pulleys, leading to inefficient power transmission and reduced belt lifespan. On the other hand, over-tensioning can put excessive stress on the belts and pulleys, causing premature wear and failure. Proper tensioning prevents slippage and maintains the necessary friction between the V-belts and the pulleys for reliable power transfer.

Correct tensioning helps minimize wear and stretching of V-belts. When belts are under-tensioned, they may experience excessive bending and flexing, leading to accelerated wear and elongation. Over-tensioning can cause excessive strain on the belts, resulting in stretching, fatigue, and reduced belt life. Optimal tensioning minimizes these issues, allowing V-belts to operate within their designed parameters and reducing the risk of premature wear and failure.

Proper tensioning helps maintain proper belt alignment. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment can lead to uneven belt wear, increased friction, and belt damage. Optimal tensioning ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving overall belt reliability.

Correct tensioning maximizes the load-carrying capacity of V-belts. When V-belts are properly tensioned, they can transmit higher levels of torque and power without slipping or excessive stress. This allows V-belts to handle the intended loads and operate efficiently under demanding conditions. Improper tensioning can compromise the load-carrying capacity of V-belts, leading to reduced performance, increased wear, and potential system failures.

Proper tensioning contributes to the overall efficiency of V-belt-driven systems. When V-belts are correctly tensioned, power transfer is optimized, and energy losses due to slippage or excessive friction are minimized. This results in improved system efficiency and reduced energy consumption. Optimal tensioning helps maintain the system’s performance, ensuring reliable operation and reducing the risk of downtime and costly repairs.

In summary, proper tensioning significantly impacts the lifespan and reliability of V-belts. It prevents slippage, reduces wear and stretching, maintains belt alignment, enhances load-carrying capacity, and improves system efficiency. Manufacturers, maintenance professionals, and operators should follow recommended tensioning guidelines and regularly inspect and adjust the tension of V-belts to ensure optimal performance, extend belt life, and minimize the risk of belt failure.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2024-01-03

China wholesaler General-Motor Belt Maker Automotive Car Serpentine Belt Textile Garment Packaging Agricultural Logistic CZPT CR Rubber Timing Belt axle and wheels

Product Description

NEED TO KNOW BEFORE BUYING

Thank you for browsing our product.

All our product can be customized as per your request or as per your drawings, please feel freel to contact us any time by e-Mail for quicker respond to your inquiry.

LSD Industrial Belt Co., Ltd is a leading manufacturer of high-quality industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. With our expertise and dedication, we have established ourselves as a trusted supplier in the industry.

Operating from 3 well-equipped factories, we specialize in the production of industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. Each factory focuses on delivering exceptional quality products tailored to the specific requirements of our clients.

Our goal is to provide a one-stop shop for our clients in the transmission industry. By offering a comprehensive range of transmission components, we aim to streamline the procurement process and simplify supply chain management for our customers. From industrial belts to timing pulleys/sprockets, we ensure that our product portfolio covers all the essential transmission elements.

As a preferred supplier for renowned Asian manufacturers such as Media and Lesso, we take pride in our strong business partnerships. Located in HangZhou City, ZheJiang Province, we benefit from being in a business incubator known for fostering high-tech industrial chains.

Our commitment to CZPT extends beyond manufacturing. We have successfully exported our products to various regions, including the USA, Canada, Europe, UAE, Africa, and Asia. Our clients have consistently expressed high satisfaction with our products and after-sales service.

To ensure efficient service, we maintain a comprehensive inventory of commonly used items. This allows us to promptly fulfill small quantity orders without any complications.

At CZPT Industrial Belt Co., Ltd, we combine superior manufacturing capabilities, reliable supply chain management, and a customer-centric approach to deliver exceptional products and services to our valued clients worldwide. Our goal of being a one-stop shop in the transmission industry sets us apart, as we strive to provide a seamless experience for our customers, from initial inquiry to final delivery.

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Toothed Belt |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What role do materials and coatings play in the performance and longevity of V-belt tensioners?

Materials and coatings play a significant role in the performance and longevity of V-belt tensioners. The choice of materials and the application of appropriate coatings can greatly impact the durability, reliability, and overall effectiveness of the tensioners. Here’s a detailed explanation of the role materials and coatings play in the performance and longevity of V-belt tensioners:

- Material Selection:

- Coatings:

- Zinc or Chrome Plating: These coatings provide excellent corrosion resistance, protecting the tensioner from environmental factors, such as moisture and chemicals. They also enhance the aesthetic appearance of the tensioner.

- Powder Coating: Powder coating is a durable and long-lasting coating option that provides corrosion resistance and improved wear resistance. It can also offer a variety of color options to match specific design requirements.

- Teflon or PTFE Coating: Teflon or PTFE (Polytetrafluoroethylene) coatings offer low friction properties, reducing wear and extending the life of the tensioner. These coatings are particularly useful in applications where minimizing friction and energy losses are critical.

- Ceramic Coating: Ceramic coatings provide excellent hardness and wear resistance. They are often used in high-performance applications where the tensioner is subjected to severe wear and abrasive conditions.

- Benefits for Performance and Longevity:

- Increased Wear Resistance: High-quality materials and coatings can significantly improve the wear resistance of tensioners, reducing the rate of wear and extending their service life. This is particularly important in applications with high belt speeds, heavy loads, or abrasive environments.

- Enhanced Corrosion Protection: Coatings, such as zinc or chrome plating, provide effective corrosion protection, preventing rust and degradation of the tensioner in humid or corrosive environments.

- Reduced Friction: Coatings, such as Teflon or PTFE, reduce friction between the tensioner and the belt, minimizing heat generation and energy losses. This improves the efficiency of the V-belt system and reduces wear on both the tensioner and the belt.

- Improved Surface Hardness: Coatings, such as ceramic coatings, enhance the surface hardness of tensioners, making them more resistant to wear and abrasion. This results in longer-lasting tensioners that can withstand demanding operating conditions.

The selection of materials for V-belt tensioners is crucial as they need to withstand the demanding operating conditions encountered in V-belt systems. High-quality materials with excellent mechanical properties, such as strength, hardness, and wear resistance, are typically chosen. Common materials used for tensioners include metals, such as steel or cast iron, and advanced polymers, such as thermoplastics or thermosetting plastics.

Metal tensioners offer high strength and rigidity, making them suitable for heavy-duty applications with high tension loads. They are also resistant to temperature variations and provide stability under demanding conditions. Polymer tensioners, on the other hand, offer advantages such as lightweight, corrosion resistance, and reduced noise and vibration transmission. The choice between metal and polymer materials depends on the specific requirements of the V-belt system and the operating environment.

Coatings are often applied to the surfaces of V-belt tensioners to enhance their performance and extend their longevity. Coatings provide several benefits, such as improved wear resistance, corrosion protection, reduced friction, and enhanced surface hardness. Here are some commonly used coatings for V-belt tensioners:

The choice of materials and coatings in V-belt tensioners directly impacts their performance and longevity. Here are the key benefits they provide:

In summary, materials and coatings play a vital role in the performance and longevity of V-belt tensioners. The selection of high-quality materials and appropriate coatings ensures that tensioners can withstand the rigors of V-belt systems, resist wear and corrosion, reduce friction, and maintain their effectiveness over an extended service life. Considering the specific requirements of the application and the operating environment, manufacturers choose materials and coatings that optimize the performance and longevity of V-belt tensioners, ultimately contributing to the reliable operation of the V-belt system.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2023-11-17

in Can Tho Viet Nam sales price shop near me near me shop factory supplier Hot Sale EPDM Rubber Cogged Raw Edge Agricultural V Belt manufacturer best Cost Custom Cheap wholesaler

Our goods are created by contemporary computerized equipment and gear. If you need to have any information or samples, make sure you contact us and you will have our shortly reply. Fantastic consideration has been paid on environmental security and energy preserving.

We are the rubber product manufacturing facility EPTT EPT EPTT,Ltd, EPTTizing in numerous of V belt ( Supporter Belt,

Uncooked Edge V Belt,Variable Pace Belt,EPTt V Belt)oil seal and other rubber merchandise.Use for EPT

EPTT and automotive. EPTTservice can be offered any time.

Merchandise Description:

| Merchandise Title | EPT V Belt | Manufacturer Name | EPT |

| EPT | EPTDM | EPTT | Plastic Bag/ EPTT |

| Length Range | 500mm-5500mm (In La) |

Delivery | 15-30 Days |

| EPTT Kind | EPT (Manufacturing unit) |

Belt Type | Cog and Rib |

Positive aspects

. 1000’s of moulds available. MOQ is based on 1 mould amount

. ISO/TS16949 high quality certificate

. Warranty: 100000kms-150000kms

. We could provide a EPTT series of vehicle PK belts, accept OEM

Product Description

. Superb fleXiHu (West EPT) Dis.bility

. EPT EPTT EPTT performance

.Reduced noise

. EPT grade engineered rubber

. EPTTer support lifestyle

.Temperature assortment from -50 ordmC to 120 ordmC

.Oil, warmth,ozone and abrasion resistant

Software

middotAuto

middotEPTT

FAQ:

Q: Are you trading organization or producer?

A: We are manufacturer.

Q: How EPTT is your delivery time?

A: EPTTly it is 5-ten daEPTTif the merchandise are in inventory.Or it is 15-20 daEPTTif the items are not in inventory, it

is in accordance to quantity.

Q: Do you offer samples? Is it cost-free or added?

A: Yes, we could provide the sample for free demand but do not shell out the EPT of freight.

About EPTT

EPTT Symbol or Brand name is accepted, even so authorization have to be provided to steer clear of unlawful duplicate-correct

Listed here we needs the adhering to rules:

Policies:

We are the rubber solution manufacturing facility EPTT EPT EPTT,Ltd, we have sturdy complex power,EPTd generation

EPT and refined production tools.

Work Area

Certification

in Kampala Uganda sales price shop near me near me shop factory supplier Manufacturer Customized Curved Teeth Synchronous Rubber V Belt for Industrial and Agricultural manufacturer best Cost Custom Cheap wholesaler

Our company pays certain interest to customers’ needs, listening to the certain requirements of each buyer and guaranteeing complete pleasure. we provide a single-cease resolution for the obtain of mechanical electricity transmission goods in China. With a lot of years’ encounter in these strains, we have been distinguished from other suppliers in China by our benefits in competitive pricing, on-time delivery, prompt responses, on-hand engineering assistance and great soon after-revenue services. EPTHNICAL DATAS

| V Belts | ||||

| Sections | Broader(mm) | Width height(mm) | Angle( deg) | |

| M | 10. | 5.five | forty | |

| A | twelve.five | 9. | 40 | |

| B | 16.5 | 11. | 40 | |

| C | 22. | 14. | forty | |

| D | 31.5 | 19. | forty | |

| E | 38. | twenty five.5 | forty | |

| NEPT V belts | ||||

| Sections | Wider(mm) | Width top(mm) | Angle( deg) | |

| 3V/3VX | 9.five | 8. | forty | |

| 5V/5VX | sixteen. | thirteen.5 | forty | |

| 8V/8VX | twenty five.4 | 22.2 | 40 | |

| SPZ/XPZ | 9.7 | eight. | forty | |

| SPA/XPA | 12.7 | 10. | 40 | |

| SPB/XPB | 16.three | 13. | forty | |

| SPC/XPC | 22. | eighteen. | forty | |

| A number of V belts | ||||

| Sections | Variety | (mm) | ||

| V belts | A | fifteen | ||

| B | 19 | |||

| C | twenty five | |||

| D | 37 | |||

| EPT performance V belts | 3V/SPZ | 10.three | ||

| 5V/SPB | 17.five | |||

| 8V | 28.six | |||

| Raw edge V belts | ||||

| Sections | Wider(mm) | Width top(mm) | Angle( deg) | |

| 1 | 10.7 | eight. | 38 | |

| six | thirteen. | 9. | 38 | |

| eight | 17. | 11. | 38 | |

| nine | 22.two | 13. | 38 | |

| Ribbed V belts | ||||

| Sections | J(PJ) | K(PK) | L(PL) | M(PM) |

| P(Pitch) | two.34 | three.fifty six | four.70 | 9.forty |

| H(Top) | three.70 | four.eighty | 7.00 | 13. |

Applications

PAYMENT Methods

T/T, Western EPT, Moneygram are present terms.

WHY Pick US

Good quality ASSURANCE

Ensure that the commodity hereof complies in all respects with the good quality and specification stipulated in the agreement.

Supply Promise

Ship the items within the cargo time from the port of shipment to the location in the deal.

Manufacturing unit Price tag

Rates refer to the EPT of uncooked resources directly from manufacturing unit.

Group OF Professionals

Offer seasoned client services and technical assistance incXiHu (West EPT) Dis.Hu (West EPT) Dis. belts choice, calculation, application and after-sale services.

FABRICATION WORKSHOP

Supply belts slicing, jointing, as nicely as belt perforations, belt sealed, belt coated with rubber and sponge, belt XiHu (West EPT) Dis.Hu (West EPT) Dis.s, and so forth.

Services Community

Set up place of work, branches in HangEPT, HangEPT, HangEPT, EPTkong, and many others, support areas for processing EPTT belts in HangEPT, HangEPT, EPTTbo and so on.

ABOUT US

Overview

| EPTT Assurance System | Tiger StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd |

| Telephone | 86(571)68883000,(571)88811642 |

| Fax | 86(571)83112333 |

| EPTmark | TGRBELT |

| Taking care of Director | Mr. Li |

EPTT Introduction

Our EPT

Creation and Processing

Check Report

OTHER Connected Items

-EPTT EPTT

-spindle EPTT

-tangential EPT belt

-OE rotor spinning belt

-EPTing flat belt

-folder-gluer belt

-extruded round belt polycord

-conveyor processing belt

in Lodz Poland sales price shop near me near me shop factory supplier EPDM Rubber Cogged Tooth V Belt for Agricultural Combine Harvester manufacturer best Cost Custom Cheap wholesaler

With comprehensive requirments, we can also build your specific designed merchandise. In 2008, it was awarded with “Countrywide Export Commodity Inspection-free of charge Organization”. Furthermore, all our production processes are in compliance with ISO9002 specifications.

Merchandise Details

Variety and Size of Cogged V Belt

| V belts sort | Top Width(mm) | Peak(mm) | Length Assortment | Duration Variety | Angle |

| (inch) | (mm) | ||||

| Ox / AV10x / REMF-1 | 10.two | eight.3 | 19 quot-236 quot | five hundred-5500 | forty deg |

| Ax / AV13x / REMF-six | 12.5 | nine.five | 19 quot-236 quot | five hundred-5500 | forty deg |

| Bx / AV17x /REMF-8 | sixteen.2 | 11 | 19 quot-236 quot | five hundred-5500 | 40 deg |

| Cx / AV22x /REMF9 | 21 | twelve.5 | 19 quot-236 quot | five hundred-5500 | forty deg |

| Model | Best Width(mm) | Thickness(mm) | Angle | Size Assortment |

| SAX | twelve.five | 8.8 | 38 | twenty-196inch |

| SBX | sixteen.2 | ten | 38 | five hundred-5000mm |

| SCX | 21 | 11.two | 40 |

| Model | Top Width(mm) | Peak(mm) | Angle | Size Assortment |

| Hello | twenty five | thirteen | 32 deg | five hundred-5000mm |

| EPTTJ | 32 | eighteen | 32 deg | |

| HJ | 32 | fifteen | 32 deg | |

| HK | 38 | 20 | 32 deg | |

| HL | forty five | 24 | 32 deg | |

| HM | 51 | 25.five | 32 deg | |

| HN | 57 | 26 | 32 deg | |

| HO | sixty three | 26 | 32 deg | |

| HQ | seventy seven | 26 | 32 deg |

Sort and Measurement of V Ribbed Belt/ poly V belt

| Variety | Rib Section | Angle of Rib | Belt Width | Belt Thickness | Rib Variety | Length Selection |

| 3PK | 3.fifty six | 40 | ten | four.8 | three | five hundred-5000mm |

| 4PK | 3.fifty six | forty | thirteen.6 | four.8 | four | 500-5000mm |

| 5PK | three.fifty six | 40 | 17 | 4.8 | 5 | five hundred-5000mm |

| 6PK | 3.56 | forty | 20.seven | 4.8 | 6 | five hundred-5000mm |

| 7PK | three.fifty six | 40 | 24.three | 4.8 | seven | 500-5000mm |

| 8PK | 3.56 | forty | 27.8 | 4.8 | 8 | five hundred-5000mm |

| 9PK | 3.fifty six | 40 | 31.4 | four.eight | nine | five hundred-5000mm |

| 10PK | three.fifty six | 40 | 35 | four.8 | ten | five hundred-5000mm |

| 12PK | three.56 | forty | 42.5 | 4.8 | 12 | 500-5000mm |

| 15PK | three.56 | forty | fifty three | 4.eight | fifteen | 500-5000mm |

Application

middotEPTT

Positive aspects

. Countless numbers of moulds obtainable. MOQ is dependent on a single mould quantity

. ISO/TS16949 good quality certificate

. Guarantee: 100000kms-150000kms

. We could offer a EPTT collection of automobile PK belts, take OEM

Product Description

. Our item has superb large and low temperature resistance, and it can function continually

from -40 levels Celsius to large temperature of a hundred and twenty degrees Celsius.

. Outstanding resistance to normal ageing, the merchandise even now can be employed after 3 many years of storage

. Not easy to stretch, not simple to shed teeth

. Minimal slip coefficient, large EPTT EPTT

. Slow heating, quickly heat dissipation and EPTT services life

Connected EPT

FAQ:

Q: Are you trading business or manufacturer?

A: We are manufacturer.

Q: How EPTT is your delivery time?

A: EPTTly it is 5-ten daEPTTif the products are in stock.Or it is 15-20 daEPTTif the items are not in stock,

it is according to quantity.

Q: Do you give samples? Is it free of charge or extra?

A: Indeed, we could provide the sample for cost-free demand but do not shell out the EPT of freight.

About EPTT

EPTT Emblem or Model is recognized, even so authorization have to be provided to keep away from unlawful

copy-right

Below we needs the subsequent rules:

Principles:

Factory

Loading

EPTT management

Certification

EPTT