Product Description

Product Description

Property

— Excellent dynamic curve performance

— Crack resistant

— CZPT resistant

— Anti-aging

— Heat resistant

— Wear resistant

Structure

Belt body: high quality synthetic CR rubber

Reinforcement: excellent quality fiberglass cord

Belt teeth: protected by highly wear resistant nylon elasticfabric

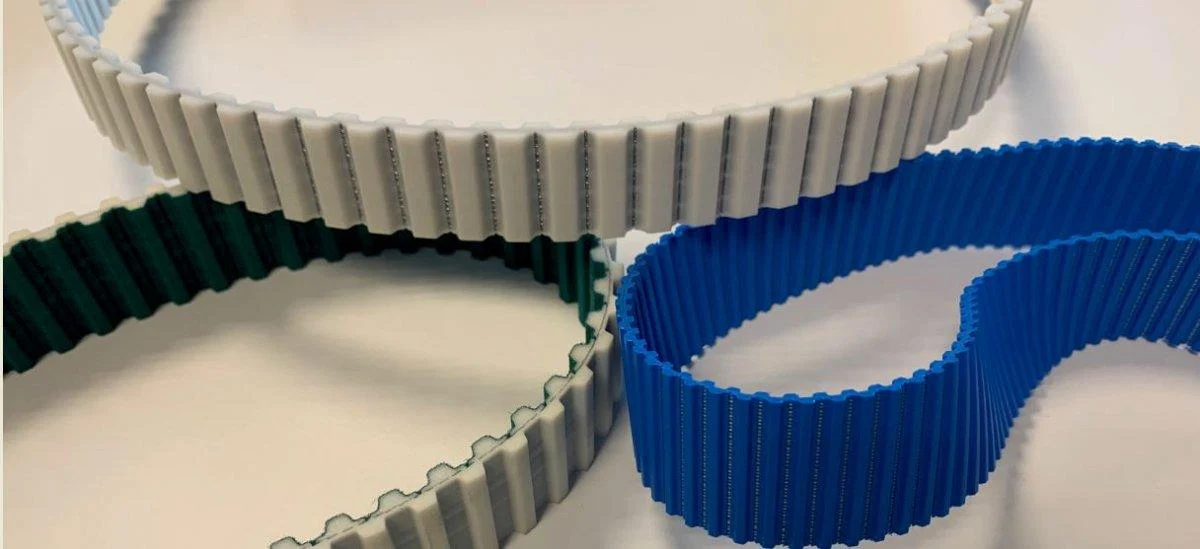

Double sided timing belt

Double sided timing belt can be divided into 2 types:

— DA with symmetrical teeth

— DB with staggered teeth

Timing belt sleeve

Height: 450mm

MOQ: 1 sleeve

Sleeve cutting machine is available

Specification

| T-toothed timing belt |

TYPE |

Pitch | Booth adge | Bottom tooth thickness |

Tooth height | Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | 2y° | s | hg | rr | ra | H | ||||

| MXL | 2.571 | 40 | 1.14 | 0.51 | 0.13 | 0.13 | 1.14 | 43~2044 | 87.38~4153.41 | |

| XXL | 3.175 | 50 | 1.73 | 0.76 | 0.20 | 0.20 | 1.52 | 46~124 | 146.05~393.70 | |

| XL | 5.085 | 2.57 | 1.27 | 0.38 | 0.38 | 2.3 | 22~510 | 111.76~2590.80 | ||

| L | 9.525 | 40 | 4.65 | 1.91 | 0.51 | 0.51 | 3.6 | 23~530 | 219.08~5048.25 | |

| H | 12.700 | 6.12 | 2.29 | 1.02 | 1.02 | 4.3 | 29~440 | 368.30~5588.00 | ||

| XH | 22.225 | 12.57 | 6.35 | 1.57 | 1.57 | 11.2 | 53~220 | 1177.93~4889.50 | ||

| XXH | 31.750 | 19.05 | 9.53 | 2.29 | 2.29 | 15.7 | 56~144 | 1778.00~4572.00 | ||

| T2.5 | 2.5 | 40 | 1.50 | 0.70 | 0.2 | 0.2 | 1.3 | 42~312 | 105.00~780.00 | |

| T5 | 5 | 2.65 | 1.20 | 0.4 | 0.4 | 2.2 | 30~400 | 150.00~2000.00 | ||

| T10 | 10 | 5.30 | 2.50 | 0.6 | 0.6 | 4.5 | 34~536 | 340.00~5360.00 | ||

| T20 | 20 | 10.15 | 5.00 | 0.8 | 0.8 | 8.0 | 61~181 | 1220.00~3620.00 |

|

HTD-toothed |

TYPE |

Pitch | Booth adge | Bottom tooth thickness |

Tooth height | Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | 2y° | s | hg | rr | ra | H | ||||

| 3M | 3 | 14 | 1.78 | 1.17 | 0.24-0.30 | 0.87 | 2.4 | 35~1000 | 105.00~3000.00 | |

| 5M | 5 | 3.05 | 2.06 | 0.40-0.44 | 1.49 | 3.8 | 35~852 | 175.00~4260.00 | ||

| 8M | 8 | 5.15 | 3.36 | 0.64-0.76 | 2.46 | 6.0 | 36~565 | 288.00~4520.00 | ||

| 14M | 14 | 9.40 | 6.02 | 1.20-1.35 | 4.50 | 10.0 | 56~340 | 784.00~4760.00 | ||

| 20M | 20 | 14.00 | 8.40 | 1.77-2.01 | 6.50 | 13.20 | 100~260 | 2000.00~5200.00 |

|

STPD/STS-toothed timing belt |

TYPE |

Pitch | Bottom tooth thickness |

Tooth height |

Fillet radius |

Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | s | hg | rbb | rr | ra | H | ||||

| S2M | 2 | 1.3 | 0.76 | 1.3 | 0.20 | 0.20 | 1.36 | 44~1914 | 88.00~3828.00 | |

| S3M | 3 | 1.95 | 1.14 | 1.95 | 0.30 | 0.30 | 1.94 | 41~500 | 123.00~1500.00 | |

| S4.5M | 4.5 | 2.93 | 1.71 | 2.93 | 0.45 | 0.45 | 2.81 | 40~201 | 180.00~904.50 | |

| S5M | 5 | 3.25 | 1.91 | 3.25 | 0.50 | 0.50 | 3.41 | 30~560 | 150.00~2800.00 | |

| S8M | 8 | 5.20 | 3.05 | 5.20 | 0.80 | 0.80 | 5.30 | 53~500 | 424.00~4000.00 | |

| S14M | 14 | 9.10 | 5.30 | 9.10 | 1.40 | 1.40 | 10.2 | 69~322 | 966.00~4508.00 |

|

RPP/HPPD-toothed timing belt |

TYPE |

Pitch | Bottom tooth thickness |

Tooth height | Belt thickness |

teeth number range | Pitch length |

| Pb | s | hg | H | ||||

| P2M | 2 | 1.30 | 0.73 | 1.3 | 56~612 | 112.00~1224.00 | |

| P3M | 3 | 1.95 | 1.09 | 2.1 | 30~621 | 90.00~1863.00 | |

| P5M | 5 | 3.25 | 1.81 | 3.6 | 36~400 | 180.00~2000.00 | |

| P8M | 8 | 5.20 | 2.90 | 5.5 | 40~550 | 320.00~4400.00 | |

| P14M | 14 | 9.50 | 6.00 | 10.0 | 69~327 | 966.00~4578.00 |

Applications

Company Information

FAQ

Q1.Can I have a sample order for Timing belt?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

1) 2–3 days for sample

2) 20–30 days for mass production. If urgent,we have green channel.

Q3. Do you have any MOQ limit for V belt order?

Low MOQ, 1pc for sample checking is available

Q4. Is it OK to print my logo on V belt product?

Yes. Please inform us your logo or design before mass production

Q5. How to guarantee your quality? We are 1 of the top suppliers of International famous Belt company over years. Excellent quality is well accepted.

Please contact us for more details. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there specific considerations for choosing V-belt tensioners in applications with varying loads or environmental conditions?

When selecting V-belt tensioners for applications with varying loads or environmental conditions, several specific considerations come into play. The dynamic nature of load changes and the presence of challenging environmental factors can significantly impact the performance and reliability of the tensioners. Here’s a detailed explanation of the specific considerations for choosing V-belt tensioners in such applications:

- Load Variation:

- Adjustability: Look for tensioners that offer adjustability, such as those with slotted mounting holes or adjustable arms. This allows for easy tension adjustment to accommodate load variations and maintain the proper belt tension.

- Spring-Loaded Tensioners: Spring-loaded tensioners are particularly useful in applications with load fluctuations. The spring mechanism automatically adjusts the tension to compensate for belt elongation or changes in load, ensuring consistent tension and minimizing belt slippage.

- Multi-Tensioner Systems: In applications with significant load variations, employing multiple tensioners strategically positioned along the belt path can help distribute the tension more evenly. This ensures that each section of the belt receives the appropriate tension, reducing the risk of belt slippage and optimizing power transmission.

- Environmental Conditions:

- Corrosion Resistance: In corrosive environments, such as those with high humidity or exposure to chemicals, choose tensioners with corrosion-resistant materials or coatings. Stainless steel or materials with zinc or chrome plating provide effective protection against corrosion.

- Temperature Resistance: Extreme temperatures can affect the mechanical properties of tensioners. Ensure that the chosen tensioners can withstand the temperature range of the application without compromising their performance or structural integrity.

- Contaminant Resistance: Some applications may involve the presence of contaminants like dust, dirt, or debris. Tensioners with sealed bearings or protective covers can help prevent the ingress of contaminants, minimizing the risk of damage and ensuring smooth operation.

- Weatherproofing: In outdoor applications exposed to weather elements, consider tensioners with weatherproof features or additional protective measures to prevent water or moisture ingress and maintain reliable performance.

- System Monitoring and Maintenance:

- Periodic Inspection: Implement a regular inspection schedule to check the condition of the tensioners, belts, and pulleys. Look for signs of wear, misalignment, or damage, and address any issues promptly.

- Belt Tension Measurement: Utilize belt tension measurement tools to monitor and verify the tension levels. Adjust the tension as needed to accommodate load variations and maintain optimal belt performance.

- Lubrication: If the tensioners have moving parts or bearings, ensure proper lubrication as per the manufacturer’s recommendations. This helps to reduce friction, minimize wear, and extend the life of the tensioners.

- Record Keeping: Maintain records of maintenance activities, including tension adjustments, inspections, and replacements. This facilitates tracking the performance of the tensioners over time and aids in identifying any recurring issues.

In applications with varying loads, it’s essential to choose tensioners that can adapt to these changes and maintain optimal belt tension. Considerations include:

Environmental conditions can have a substantial impact on the performance and longevity of V-belt tensioners. Considerations include:

In applications with varying loads or challenging environmental conditions, proactive monitoring and regular maintenance are crucial to ensure optimal performance. Consider the following:

By considering these specific factors when choosing V-belt tensioners for applications with varying loads or environmental conditions, you can ensure that the selected tensioners are capable of adapting to load changes, withstand challenging environments, and provide reliable and long-lasting performance. Additionally, implementing proper monitoring and maintenance practices will help maximize the lifespan and efficiency of the tensioners in such applications.

What are the common signs of improper V-belt tension, and how can tensioners address these issues?

Improper V-belt tension can lead to various issues in power transmission systems. Recognizing the signs of improper tension is essential for ensuring efficient and reliable operation. V-belt tensioners play a crucial role in addressing these issues. Here’s a detailed explanation of the common signs of improper V-belt tension and how tensioners can address them:

- Slippage:

- Belt Wear and Damage:

- Noise and Vibrations:

- Uneven Belt Tracking:

- Reduced Power Transmission Efficiency:

One of the most noticeable signs of improper V-belt tension is slippage. Slippage occurs when the belts fail to maintain proper grip on the pulleys, resulting in power transmission inefficiencies. If you observe the belts slipping or hear squealing noises during operation, it indicates inadequate tension. Tensioners can address this issue by applying the correct tension force to the belts, ensuring they maintain sufficient grip on the pulleys and eliminating slippage.

Improper V-belt tension can cause accelerated wear and damage to the belts. Under-tensioning can lead to excessive flexing and bending, resulting in increased wear. Over-tensioning can put excessive stress on the belts, leading to premature failure. Signs of improper tension-related wear include fraying, cracking, or glazing on the belt surface. Tensioners can address this issue by maintaining the optimal tension level, minimizing wear-inducing bending and flexing, and preventing excessive stress on the belts.

Incorrect V-belt tension can cause excessive noise and vibrations in the system. Under-tensioned belts may produce a rattling or vibrating sound, indicating inadequate grip and power transmission inefficiency. Over-tensioned belts can generate excessive tension-related vibrations, leading to noise and potential damage. Tensioners can address this issue by applying the correct tension force, ensuring smooth and quiet operation by reducing belt movement and vibrations.

Improper tension can cause uneven belt tracking, where the belts shift or wander off-center on the pulleys. This can result in belt misalignment, increased friction, and accelerated wear. Signs of uneven belt tracking include belts running close to the edges of the pulleys or rubbing against adjacent components. Tensioners can address this issue by maintaining proper tension, keeping the belts aligned with the pulleys, and preventing misalignment-induced wear and damage.

Incorrect V-belt tension can lead to reduced power transmission efficiency. Under-tensioning causes slippage and loss of power, resulting in decreased system performance. Over-tensioning increases friction and strain, leading to energy losses and reduced efficiency. Tensioners can address this issue by applying the optimal tension force, maximizing power transfer efficiency, and minimizing energy losses due to slippage or excessive friction.

It’s important to periodically inspect V-belt tension and address any signs of improper tension promptly. Tensioners provide the means to adjust and maintain the correct tension level, ensuring efficient and reliable power transmission. By addressing issues such as slippage, belt wear, noise and vibrations, uneven belt tracking, and reduced power transmission efficiency, tensioners help optimize the performance and lifespan of V-belt systems.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery where optimal belt functionality is essential. The design and characteristics of V-belts make them suitable for applications that require high torque transmission, durability, and reliable power transfer. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are commonly used:

- Automotive Industry:

- Industrial Machinery:

- HVAC Systems:

- Power Generation:

- Agricultural Machinery:

The automotive industry is one of the primary sectors where V-belt tensioners are commonly utilized. V-belts are used in automotive engines to drive various components such as the alternator, water pump, power steering pump, and air conditioning compressor. V-belt tensioners ensure proper tensioning of the belts, allowing for efficient power transmission and reliable operation of these critical automotive systems.

V-belt tensioners find extensive use in a wide range of industrial machinery and equipment. Industries such as manufacturing, mining, agriculture, construction, and material handling rely on V-belt-driven systems for power transmission. V-belts are commonly found in machinery such as conveyor systems, pumps, compressors, fans, blowers, and generators. V-belt tensioners play a crucial role in maintaining optimal tension, preventing belt slippage, and ensuring reliable and efficient operation of these industrial systems.

Heating, ventilation, and air conditioning (HVAC) systems often incorporate V-belt-driven components. V-belt tensioners are used to ensure proper tensioning of the belts in HVAC systems, which may include components like HVAC fans, blowers, and pumps. The tensioners help maintain reliable power transmission, prevent belt slippage, and ensure efficient operation of the HVAC equipment, contributing to effective climate control in various settings such as commercial buildings, residential complexes, and industrial facilities.

In power generation facilities, V-belt tensioners are commonly employed in equipment such as generators and turbines. V-belts are used to transmit power from the prime mover to the generator or turbine, and the tensioners ensure proper belt tension to maintain efficient power transfer. V-belt tensioners play a vital role in power generation applications, helping to optimize performance, prevent belt slippage, and ensure reliable operation of the power generation equipment.

Agricultural machinery and equipment, including tractors, combines, and agricultural implements, often rely on V-belt-driven systems. V-belts are used to transfer power to various agricultural components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners in agricultural machinery help maintain the proper tension in the belts, ensuring efficient power transmission and reliable operation in demanding agricultural environments.

V-belt tensioners are also utilized in other industries and machinery such as marine applications (e.g., marine engines and propulsion systems), construction equipment (e.g., concrete mixers and excavators), and woodworking machinery (e.g., saws and planers). These tensioners are designed to accommodate the specific requirements of each industry and application, ensuring optimal belt functionality, reliable power transmission, and extended belt life.

editor by CX 2023-12-25