Product Description

Company Profile

ZHangZhoug INJ transmission systems Co.,ltd located in HangZhou, ZHangZhoug province,was founded in 2003. We are a professional supplier of domestic and imported transmission belts. We have good experience and technology in stone\ceramic\wood\textiles\tobacco\logistics\firecrackers\medicine\glass\steel\automotive\electronics\beverages\spices\paper\printing\cable. Welcome all customers to contact us any time to investigate and negotiate.

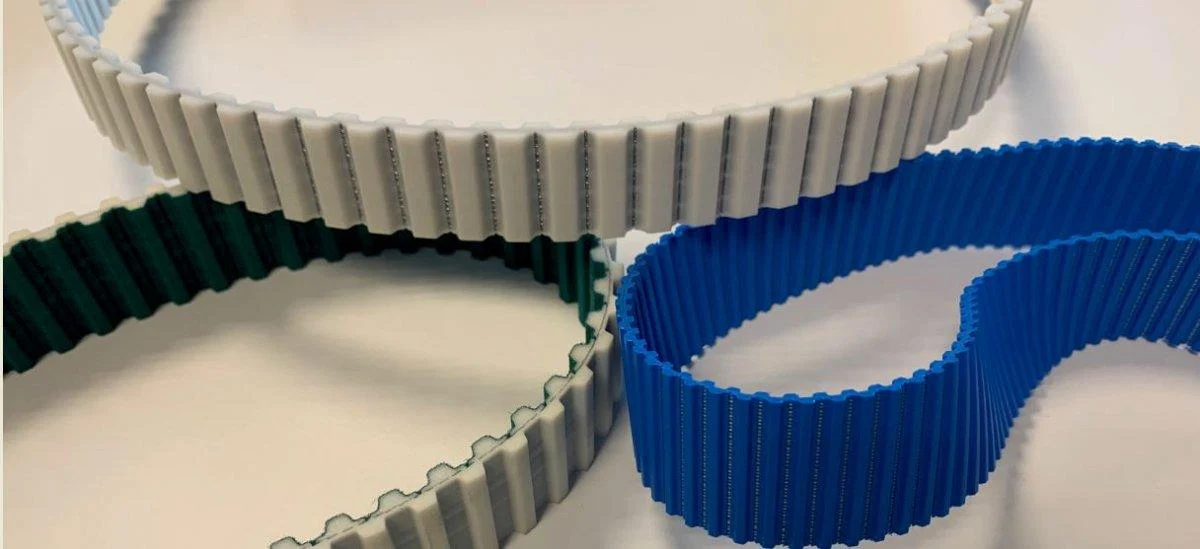

Raw Materials

Belt: High-quality neoprene (CR)as the main raw materials(imported from Japan)

Skeleton materials: Glass Fiber(imported from Janpan)

Tooth surface: Nylon 66 high

Product Features

*1: High-efficiency factor and extreme tensile strength

*2: Extraordinarily resistance on cold & heat (-40ºC-120ºC), oil and CZPT

*3: Excellent aging-resistance and abrasion-resistance

*4: Slip-free transmission and low noise

Product Description

Toothed wedge belts are widely used in the transmission system of flour mills. Its outer circle is a timing belt, and its inner circle is a multi-ribbed belt, which can eliminate the deviation of the pulley. It has excellent bending performance, low noise, accurate transmission ratio and efficiency. The characteristics of high power, high power, energy saving, no need for lubrication, will not cause lubrication pollution, so it is especially suitable for food, paper and textile machinery.

| TYPE | SUPPLY CHARACTERISTIC |

| MXL XXL XL L H XH XXHT 2.5 T5 T10 T20 AT5 AT10 AT 20 HTD:2M 3M 5M 8M 14M 20M STS:S2M S3M S4.5M S5M S8M S14M RPP:RP2M RP3M RP5M RP8M RP14M |

1. Company leading products with more than 4000 moulds. 2. Cutting or provide sleeve according to customer’s requirement. 3. Anti-static, oil, heat-resistant,low temperature resistance ect. |

Property of Timing Belt

| Test Item | Test Result |

| Tension strength (≥KN/25.4mm) | 0.59-10.8 (according to types) |

| Elongation (≤ % ) | 4.0 (all types) |

| Loading (KN/25.4mm) | 0.49-8.64 (according to types) |

Common Specifications and Models

| HTD5M | 350-HTD5M-25 | RPP5M | 420-RPP5M-25 | STD8M | 1552-STD8M-12PK |

| 400-HTD5M-25 | RPP8M | 1760-RPP8M-34PL | 1552-STD8M-14PK | ||

| 425-HTD5M-25 | 1200-RPP8M-24PK(85) | 1552-STD8M-16PK | |||

| HTD8M | 1080-HTD8M-24PK | 1200-RPP8M-28PK(100) | 1552-STD8M-16PK(56.96) | ||

| 1200-HTD8M-12PL | 1250-RPP8M-24PK(85) | 1552-STD8M-30PK | |||

| 1200-HTD8M-24PK | 1280-RPP8M-24PK(85) | 1552-STD8M-30PK(106.8) | |||

| 1200-HTD8M-24PK(85) | 1368-RPP8M-24PK(85) | 1552-STD8M-36PK | |||

| 1200-HTD8M-28PK(100) | 1368-RPP8M-48PK | 1552-STD8M-60PK | |||

| 1280-HTD8M-24PK(85) | 1400-RPP8M-28PK(100) | 1600-STD8M-12PK | |||

| 1368-HTD8M-24PK(85) | 1440-RPP8M-24PK(85) | 2400-STD8M-36PK | |||

| 1400-HTD8M-28PK(100) | 1440-RPP8M-28PK | 2800-STD8M-11PK | |||

| 1440-HTD8M-12PK | 1440-RPP8M-28PK(100) | DPL | DPL1760-28PL | ||

| 1440-HTD8M-24PK(85) | 1440-RPP8M-36PK | DPL1765-22PL | |||

| 1440-HTD8M-28PK | 1440-RPP8M-48PK | DPL1765-26PL | |||

| 1440-HTD8M-28PK(100) | 1520-RPP8M-28PK(100) | DPL1765-28PL | |||

| 1440-HTD8M-48PK | 1552-RPP8M-28PK | DPL1965-22PL | |||

| 1520-HTD8M-28PK(100) | 1600-RPP8M-24PK | DPL1965-26PL | |||

| 1552-HTD8M-30PK | 1600-RPP8M-24PK(85) | DA | DA-1400-STD14M-120 | ||

| 1600-HTD8M-12PK | 1760-RPP8M-12PK | DA-1400-HTD14M | |||

| 1600-HTD8M-24PK(85) | 1760-RPP8M-15PK | DA-1200-HTD8M | |||

| 1680-HTD8M-12PK | 1760-RPP8M-16PK | DA-1200-HTD8M-100 | |||

| 1760-HTD8M-12PK | 1760-RPP8M-18PK | DA-1400-HTD8M | |||

| 1760-HTD8M-21PK(75) | 1760-RPP8M-21PK(75) | DA-1400-HTD8M-100 | |||

| 1760-HTD8M-24PK(85) | 1760-RPP8M-24PK | DA-1440-HTD8M | |||

| 1760-HTD8M-28PK(100) | 1760-RPP8M-24PK(85) | DA-1600-HTD8M | |||

| 1760-HTD8M-36PK | 1760-RPP8M-26PL | DA-1600-HTD8M-100 | |||

| 1760-HTD8M-36PK(128) | 1760-RPP8M-28PK | DA-1680-HTD8M | |||

| 2000-HTD8M-12PK | 1760-RPP8M-28PK(100) | DA-1760-HTD8M | |||

| 2000-HTD8M-28PL(100) | 1760-RPP8M-36PK | DA-1760-HTD8M-100 | |||

| 2248-HTD8M-16PK | 1760-RPP8M-36PK(128) | DA-1920-HTD8M | |||

| 2800-HTD8M-16PK | 1760-RPP8M-48PK | DA-2000-HTD8M-100 | |||

| HTD10M | 1760-HTD10M-25PL | 2000-RPP8M-28PL(100) | DA-2000-HTD8M-150 | ||

| 1760-HTD10M-25PL(118) | RPP10M | 1760-RPP10M-17PL | DA-2000-HTD8M-80 | ||

| 1760-HTD10M-34PL | 1760-RPP10M-17PL(79.9) | DA-2400-HTD8M | |||

| 1760-HTD10M-34PL(160) | 1760-RPP10M-21PL | DA-2400-HTD8M-85 | |||

| 1880-HTD10M-34PL | 1760-RPP10M-25PL(118) | ||||

| HTD12M | 1740-HTD12M-34PL | 1760-RPP10M-26PL | |||

| 1740-HTD12M-34PL(160) | 1760-RPP10M-27PL | ||||

| 1848-HTD12M-34PL | 1760-RPP10M-30PL | ||||

| 1848-HTD12M-34PL(160) | 1760-RPP10M-34PL(159.8) | ||||

| 1884-HTD12M-34PL(160) | 1760-RPP10M-34PL(160) | ||||

| HTD14M | 1778-HTD14M-29PL | 1880-RPP10M-17PL | |||

| 1778-HTD14M-29PL(137) | 1880-RPP10M-34PL | ||||

| RPP12M | 1740-RPP12M-15PL | ||||

| 1740-RPP12M-17PL | |||||

| 1740-RPP12M-34PL | |||||

| 1740-RPP12M-34PL(160) | |||||

| 1764-RPP12M-28PL | |||||

| 1764-RPP12M-34PL | |||||

| 1848-RPP12M-34PL | |||||

| 1848-RPP12M-34PL(160) | |||||

| 1884-RPP12M-34PL | |||||

| 1884-RPP12M-34PL(160) | |||||

| RPP14M | 1778-RPP14M-29PL | ||||

| 1778-RPP14M-29PL(137) | |||||

Curvilinear Tooth Profile

| Gear code | Type | Pitch(mm) | Tooth height(mm) | Belt thickness(mm) |

| HTD | 3M | 3 | 1.22 | 2.40 |

| 5M | 5 | 2.06 | 3.80 | |

| 8M | 8 | 3.36 | 6.00 | |

| 14M | 14 | 6.02 | 10.00 | |

| 20M | 20 | 8.40 | 13.20 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 1.90 | |

| S4.5M | 4.5 | 1.71 | 2.81 | |

| S5M | 5 | 1.91 | 3.40 | |

| S8M | 8 | 3.05 | 5.30 | |

| S14M | 14 | 5.30 | 10.20 | |

| RPP/HPPD | P2M | 2 | 0.76 | 1.36 |

| P3M | 3 | 1.15 | 1.90 | |

| P5M | 5 | 1.95 | 3.50 | |

| P8M | 8 | 3.20 | 5.50 | |

| P14M | 14 | 6.00 | 10.0 |

Buyer Notice

1. The price is subject to the company’s actual quotation!

2. All products are strictly inspected by our company before shipment to ensure that they are shipped without problems.

3. The pictures are all taken in kind, but there will be slight chromatic aberration due to light and display, etc. Please understand.

4. Before placing an order or before purchasing, please consult the product model, specifications, etc. so that we can confirm whether the product you need is in stock.

1. Could you offer the sample for testing?

RE: If you need sample, pls contact us soon. about the sample charge, we can consult it.

2. How about the delivery date?

RE: The delivery date is depended on your quantity. Small order is about 5 days, big order 20 days.

3. Do you set the MOQ and give any discount?

RE:We do not set the MOQ. But the more you place, the more discount you will get.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | PU |

| Type: | Toothed Belt |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What role do materials and coatings play in the performance and longevity of V-belt tensioners?

Materials and coatings play a significant role in the performance and longevity of V-belt tensioners. The choice of materials and the application of appropriate coatings can greatly impact the durability, reliability, and overall effectiveness of the tensioners. Here’s a detailed explanation of the role materials and coatings play in the performance and longevity of V-belt tensioners:

- Material Selection:

- Coatings:

- Zinc or Chrome Plating: These coatings provide excellent corrosion resistance, protecting the tensioner from environmental factors, such as moisture and chemicals. They also enhance the aesthetic appearance of the tensioner.

- Powder Coating: Powder coating is a durable and long-lasting coating option that provides corrosion resistance and improved wear resistance. It can also offer a variety of color options to match specific design requirements.

- Teflon or PTFE Coating: Teflon or PTFE (Polytetrafluoroethylene) coatings offer low friction properties, reducing wear and extending the life of the tensioner. These coatings are particularly useful in applications where minimizing friction and energy losses are critical.

- Ceramic Coating: Ceramic coatings provide excellent hardness and wear resistance. They are often used in high-performance applications where the tensioner is subjected to severe wear and abrasive conditions.

- Benefits for Performance and Longevity:

- Increased Wear Resistance: High-quality materials and coatings can significantly improve the wear resistance of tensioners, reducing the rate of wear and extending their service life. This is particularly important in applications with high belt speeds, heavy loads, or abrasive environments.

- Enhanced Corrosion Protection: Coatings, such as zinc or chrome plating, provide effective corrosion protection, preventing rust and degradation of the tensioner in humid or corrosive environments.

- Reduced Friction: Coatings, such as Teflon or PTFE, reduce friction between the tensioner and the belt, minimizing heat generation and energy losses. This improves the efficiency of the V-belt system and reduces wear on both the tensioner and the belt.

- Improved Surface Hardness: Coatings, such as ceramic coatings, enhance the surface hardness of tensioners, making them more resistant to wear and abrasion. This results in longer-lasting tensioners that can withstand demanding operating conditions.

The selection of materials for V-belt tensioners is crucial as they need to withstand the demanding operating conditions encountered in V-belt systems. High-quality materials with excellent mechanical properties, such as strength, hardness, and wear resistance, are typically chosen. Common materials used for tensioners include metals, such as steel or cast iron, and advanced polymers, such as thermoplastics or thermosetting plastics.

Metal tensioners offer high strength and rigidity, making them suitable for heavy-duty applications with high tension loads. They are also resistant to temperature variations and provide stability under demanding conditions. Polymer tensioners, on the other hand, offer advantages such as lightweight, corrosion resistance, and reduced noise and vibration transmission. The choice between metal and polymer materials depends on the specific requirements of the V-belt system and the operating environment.

Coatings are often applied to the surfaces of V-belt tensioners to enhance their performance and extend their longevity. Coatings provide several benefits, such as improved wear resistance, corrosion protection, reduced friction, and enhanced surface hardness. Here are some commonly used coatings for V-belt tensioners:

The choice of materials and coatings in V-belt tensioners directly impacts their performance and longevity. Here are the key benefits they provide:

In summary, materials and coatings play a vital role in the performance and longevity of V-belt tensioners. The selection of high-quality materials and appropriate coatings ensures that tensioners can withstand the rigors of V-belt systems, resist wear and corrosion, reduce friction, and maintain their effectiveness over an extended service life. Considering the specific requirements of the application and the operating environment, manufacturers choose materials and coatings that optimize the performance and longevity of V-belt tensioners, ultimately contributing to the reliable operation of the V-belt system.

What are the common signs of improper V-belt tension, and how can tensioners address these issues?

Improper V-belt tension can lead to various issues in power transmission systems. Recognizing the signs of improper tension is essential for ensuring efficient and reliable operation. V-belt tensioners play a crucial role in addressing these issues. Here’s a detailed explanation of the common signs of improper V-belt tension and how tensioners can address them:

- Slippage:

- Belt Wear and Damage:

- Noise and Vibrations:

- Uneven Belt Tracking:

- Reduced Power Transmission Efficiency:

One of the most noticeable signs of improper V-belt tension is slippage. Slippage occurs when the belts fail to maintain proper grip on the pulleys, resulting in power transmission inefficiencies. If you observe the belts slipping or hear squealing noises during operation, it indicates inadequate tension. Tensioners can address this issue by applying the correct tension force to the belts, ensuring they maintain sufficient grip on the pulleys and eliminating slippage.

Improper V-belt tension can cause accelerated wear and damage to the belts. Under-tensioning can lead to excessive flexing and bending, resulting in increased wear. Over-tensioning can put excessive stress on the belts, leading to premature failure. Signs of improper tension-related wear include fraying, cracking, or glazing on the belt surface. Tensioners can address this issue by maintaining the optimal tension level, minimizing wear-inducing bending and flexing, and preventing excessive stress on the belts.

Incorrect V-belt tension can cause excessive noise and vibrations in the system. Under-tensioned belts may produce a rattling or vibrating sound, indicating inadequate grip and power transmission inefficiency. Over-tensioned belts can generate excessive tension-related vibrations, leading to noise and potential damage. Tensioners can address this issue by applying the correct tension force, ensuring smooth and quiet operation by reducing belt movement and vibrations.

Improper tension can cause uneven belt tracking, where the belts shift or wander off-center on the pulleys. This can result in belt misalignment, increased friction, and accelerated wear. Signs of uneven belt tracking include belts running close to the edges of the pulleys or rubbing against adjacent components. Tensioners can address this issue by maintaining proper tension, keeping the belts aligned with the pulleys, and preventing misalignment-induced wear and damage.

Incorrect V-belt tension can lead to reduced power transmission efficiency. Under-tensioning causes slippage and loss of power, resulting in decreased system performance. Over-tensioning increases friction and strain, leading to energy losses and reduced efficiency. Tensioners can address this issue by applying the optimal tension force, maximizing power transfer efficiency, and minimizing energy losses due to slippage or excessive friction.

It’s important to periodically inspect V-belt tension and address any signs of improper tension promptly. Tensioners provide the means to adjust and maintain the correct tension level, ensuring efficient and reliable power transmission. By addressing issues such as slippage, belt wear, noise and vibrations, uneven belt tracking, and reduced power transmission efficiency, tensioners help optimize the performance and lifespan of V-belt systems.

What is a V-belt tensioner, and how does it contribute to the performance of V-belt systems?

A V-belt tensioner is a mechanical device used to maintain the proper tension in V-belt systems and contribute to their overall performance. V-belts are commonly used in various applications, such as automotive engines, industrial machinery, and power transmission systems. Here’s a detailed explanation of what a V-belt tensioner is and how it enhances the performance of V-belt systems:

- Definition of a V-Belt Tensioner:

- Tension Control:

- Preventing Slippage:

- Load Distribution:

- Maintaining Belt Alignment:

A V-belt tensioner is a component designed to apply and maintain the correct tension in V-belts. It is typically a pulley or an assembly of pulleys mounted on an adjustable arm or spring-loaded mechanism. The tensioner is positioned in the belt path and exerts force on the belt to keep it properly tensioned. By controlling the tension, the V-belt tensioner ensures optimal power transmission, minimizes slippage, and promotes the longevity of the V-belt.

The primary function of a V-belt tensioner is to control the tension in the V-belt. It applies the appropriate force to maintain the desired tension, which is crucial for the efficient operation of the V-belt system. Proper tensioning prevents slippage between the belt and the pulleys, ensuring reliable power transmission and maximizing the performance of the system. The tensioner compensates for changes in belt length due to wear, thermal expansion, or other factors, allowing the V-belt to operate within its optimal tension range.

V-belt tensioners play a vital role in preventing slippage between the V-belt and the pulleys. Slippage can occur when the belt loses traction with the pulleys due to insufficient tension or excessive loads. The tensioner maintains the proper tension in the V-belt, keeping it tightly engaged with the pulleys. This prevents slippage, ensures efficient power transfer, and minimizes energy losses. By preventing slippage, the tensioner contributes to the overall performance and reliability of the V-belt system.

A V-belt tensioner helps distribute the load evenly across the V-belt and the pulleys. Even load distribution is essential to minimize localized stresses and prevent premature wear or failure of the belt. The tensioner applies tension across the entire width of the V-belt, promoting uniform contact with the pulleys and equal distribution of the load. This even load distribution enhances the lifespan of the V-belt, reduces the risk of belt damage, and ensures the reliable operation of the V-belt system.

Proper alignment of the V-belt with the pulleys is crucial for efficient power transmission and extended belt life. V-belt tensioners often incorporate features that help maintain belt alignment. These features can include guide rollers or pulley systems that guide the V-belt and prevent it from wandering or misaligning with the pulleys during operation. By ensuring correct belt alignment, the tensioner minimizes wear, reduces the risk of belt damage, and promotes the overall performance of the V-belt system.

In summary, a V-belt tensioner is a mechanical device that maintains proper tension in V-belt systems. It controls the tension in the V-belt, prevents slippage, promotes even load distribution, and helps maintain belt alignment. By performing these functions, the V-belt tensioner enhances the performance and reliability of V-belt systems in various applications. It ensures efficient power transmission, minimizes energy losses, and contributes to the longevity of the V-belt by preventing slippage, distributing the load evenly, and maintaining proper alignment.

editor by CX 2024-01-05

China OEM General Motors Transmission Belt Maker – Jiebao OEM Transmission Parts Fan Automotive Textile Garment Packaging Agricultural Machinery Std2m Timing Belt a wheel and axle simple machine

Product Description

NEED TO KNOW BEFORE BUYING

Thank you for browsing our product.

All our product can be customized as per your request or as per your drawings, please feel freel to contact us any time by e-Mail for quicker respond to your inquiry.

LSD Industrial Belt Co., Ltd is a leading manufacturer of high-quality industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. With our expertise and dedication, we have established ourselves as a trusted supplier in the industry.

Operating from 3 well-equipped factories, we specialize in the production of industrial conveyor belts, timing belts/car belts, and timing pulleys/sprockets. Each factory focuses on delivering exceptional quality products tailored to the specific requirements of our clients.

Our goal is to provide a one-stop shop for our clients in the transmission industry. By offering a comprehensive range of transmission components, we aim to streamline the procurement process and simplify supply chain management for our customers. From industrial belts to timing pulleys/sprockets, we ensure that our product portfolio covers all the essential transmission elements.

As a preferred supplier for renowned Asian manufacturers such as Media and Lesso, we take pride in our strong business partnerships. Located in HangZhou City, ZheJiang Province, we benefit from being in a business incubator known for fostering high-tech industrial chains.

Our commitment to CZPT extends beyond manufacturing. We have successfully exported our products to various regions, including the USA, Canada, Europe, UAE, Africa, and Asia. Our clients have consistently expressed high satisfaction with our products and after-sales service.

To ensure efficient service, we maintain a comprehensive inventory of commonly used items. This allows us to promptly fulfill small quantity orders without any complications.

At CZPT Industrial Belt Co., Ltd, we combine superior manufacturing capabilities, reliable supply chain management, and a customer-centric approach to deliver exceptional products and services to our valued clients worldwide. Our goal of being a one-stop shop in the transmission industry sets us apart, as we strive to provide a seamless experience for our customers, from initial inquiry to final delivery.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Toothed Belt |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the reliability and durability aspects of V-belt tensioners in ensuring consistent tension?

V-belt tensioners play a crucial role in ensuring consistent tension in V-belt systems. Reliability and durability are essential aspects of V-belt tensioners that contribute to their ability to maintain consistent tension over time. Here’s a detailed explanation of the reliability and durability aspects of V-belt tensioners in ensuring consistent tension:

- Construction Materials:

- Design and Engineering:

- Bearing Systems:

- Wear and Fatigue Resistance:

- Environmental Resistance:

The choice of construction materials significantly affects the reliability and durability of V-belt tensioners. High-quality materials with excellent strength, wear resistance, and corrosion resistance are essential for long-term performance. Common materials used in tensioner construction include robust metals, advanced polymers, and specialized alloys. These materials ensure that the tensioner can withstand the forces and operating conditions encountered in V-belt systems, such as high loads, belt tension, temperature variations, and exposure to contaminants.

The design and engineering of V-belt tensioners are critical factors in their reliability and durability. Tensioners should be designed to distribute loads evenly, minimize stress concentrations, and provide smooth operation. Advanced engineering techniques, such as finite element analysis, are employed to optimize the design and ensure structural integrity. Additionally, attention to detail in the design process helps to minimize potential failure points, improve load-carrying capacity, and enhance overall performance.

The bearing systems within V-belt tensioners are crucial for their reliable operation. High-quality bearings, such as ball bearings or roller bearings, are used to support the rotating components and withstand the radial and axial loads. Proper bearing selection, lubrication, and sealing mechanisms are essential to ensure smooth rotation, minimize friction, and prevent premature wear. Reliable bearing systems contribute to the consistent performance of the tensioner and help maintain the desired tension in the V-belt system.

V-belt tensioners are subjected to continuous cyclic loads and motion, which can lead to wear and fatigue over time. To ensure durability and reliability, tensioners are designed and constructed to resist wear and fatigue. This may involve the use of wear-resistant coatings, hardened surfaces, or specialized materials that can withstand repetitive loading without deformation or failure. By incorporating wear and fatigue-resistant features, tensioners can maintain their performance and tensioning capabilities over an extended service life.

V-belt tensioners often operate in diverse environmental conditions, including temperature extremes, humidity, dust, and chemical exposure. Reliable tensioners are designed to withstand these environmental factors and provide consistent tension regardless of the operating environment. Protective coatings, seals, and corrosion-resistant materials are employed to prevent damage from contaminants or chemical exposure. By ensuring environmental resistance, tensioners can maintain their functionality and performance, thereby ensuring consistent tension in V-belt systems.

In summary, the reliability and durability of V-belt tensioners are crucial aspects in ensuring consistent tension in V-belt systems. Construction materials, design and engineering, bearing systems, wear and fatigue resistance, and environmental resistance all contribute to the long-term performance and reliability of tensioners. By selecting high-quality tensioners that are designed and constructed to withstand the demands of V-belt applications, users can have confidence in the consistent tensioning capabilities of the tensioner, leading to reliable and efficient operation of the V-belt system.

Can you provide guidance on selecting and sizing V-belt tensioners for specific V-belt applications?

Yes, selecting and sizing V-belt tensioners for specific V-belt applications requires careful consideration of various factors. Here’s a detailed guidance on how to select and size V-belt tensioners:

- Understand the Application Requirements:

- Determine the Tensioning Force:

- Consider Belt Type and Size:

- Assess Space Constraints and Mounting Options:

- Consider Environmental Factors:

- Consult Manufacturer Specifications and Guidelines:

- Consider Maintenance and Serviceability:

- Consider Cost and Long-Term Value:

Begin by understanding the specific requirements of the V-belt application. Consider factors such as the power transmission requirements, load conditions, operating speed, and environmental conditions. This information will help determine the appropriate tension force and other specifications needed for the tensioner.

Calculate the required tensioning force for the V-belt system. The tensioning force depends on factors such as the power being transmitted, the coefficient of friction between the belt and pulleys, and the belt’s characteristics. Manufacturers typically provide tension force guidelines based on belt type and application. Ensure that the selected tensioner can provide the required tensioning force within the desired operating range.

Take into account the type and size of the V-belt being used. Different belt types, such as classical V-belts, narrow V-belts, or synchronous belts, have specific design and performance characteristics. The tensioner should be compatible with the chosen belt type and size. Consider factors such as belt width, profile dimensions, and load capacity when selecting the tensioner.

Evaluate the available space and mounting options in the application. The tensioner should be sized to fit within the available space and align properly with the pulleys. Consider factors such as the tensioner’s dimensions, mounting configurations (e.g., fixed, adjustable, spring-loaded), and accessibility for installation and maintenance.

Take into account the environmental conditions in which the V-belt system will operate. Factors such as temperature extremes, humidity, dust, and chemical exposure can impact the performance and longevity of the tensioner. Select a tensioner that is designed to withstand the specific environmental conditions of the application.

Refer to the manufacturer’s specifications and guidelines for the tensioner. Manufacturers often provide detailed information on tensioner selection, including tension force ranges, belt compatibility, operating limits, and installation instructions. Consult these resources to ensure the chosen tensioner meets the application requirements and aligns with industry standards.

Evaluate the tensioner’s maintenance and serviceability requirements. Consider factors such as the ease of tension adjustment, access for inspection and maintenance, and the availability of replacement parts. A tensioner that is easy to maintain and service can contribute to the longevity and reliability of the V-belt system.

Finally, consider the cost and long-term value of the tensioner. Evaluate factors such as the initial purchase cost, expected lifespan, and the overall value provided by the tensioner in terms of performance, reliability, and maintenance requirements. While it’s important to consider budget constraints, prioritize selecting a tensioner that meets the application requirements and offers long-term value rather than solely focusing on the upfront cost.

By following these guidelines and considering the specific requirements of the V-belt application, you can select and size V-belt tensioners that are well-suited for the intended use. Remember to consult manufacturers’ specifications and guidelines for detailed information and to ensure proper integration and optimal performance of the tensioner within the V-belt system.

How do V-belt tensioners differ from other types of belt tensioners in terms of design and application?

V-belt tensioners differ from other types of belt tensioners in terms of their design and application. While there are various types of belt tensioners used in different systems, V-belt tensioners are specifically designed to accommodate the unique characteristics and requirements of V-belt systems. Here’s a detailed explanation of how V-belt tensioners differ from other types of belt tensioners:

- Design:

- Application:

- Tensioning Mechanism:

- Belt Compatibility:

- System Performance:

V-belt tensioners are designed to work specifically with V-belt systems, which use trapezoidal-shaped belts and pulleys. The tensioner is typically a pulley or an assembly of pulleys mounted on an adjustable arm or a spring-loaded mechanism. The pulley(s) in a V-belt tensioner have a V-shaped groove that matches the profile of the V-belt, allowing the belt to fit securely and maintain proper tension. The design of V-belt tensioners takes into account the shape, geometry, and dimensions of V-belts, ensuring effective tensioning and reliable power transmission.

V-belt tensioners are primarily used in systems that utilize V-belts, such as automotive engines, industrial machinery, and power transmission systems. V-belts are commonly employed in applications where high torque transmission is required, and they are known for their efficiency, durability, and ability to handle heavy loads. V-belt tensioners are specifically designed to address the unique requirements of these V-belt systems. They provide the necessary tension to keep the V-belt properly tensioned, prevent slippage, distribute the load evenly, and maintain reliable power transmission.

The tensioning mechanism in V-belt tensioners differs from those used in other types of belt tensioners. V-belt tensioners often incorporate an adjustable arm or a spring-loaded mechanism to apply and maintain the appropriate tension in the V-belt. The tensioner compensates for changes in belt length due to wear, thermal expansion, or other factors, ensuring that the V-belt operates within its optimal tension range. The tensioning mechanism in V-belt tensioners allows for easy adjustment and precise control of the tension, accommodating the specific requirements of V-belt systems.

V-belt tensioners are designed to be compatible with V-belts, which have a trapezoidal cross-section. The V-shaped groove in the tensioner pulley matches the profile of the V-belt, allowing for proper belt engagement and tensioning. Other types of belt tensioners, such as flat belt tensioners or timing belt tensioners, have different designs to accommodate the specific characteristics of their respective belts. The compatibility between V-belt tensioners and V-belts ensures optimal performance, reliable power transmission, and longevity of the belt and the system.

The design and application of V-belt tensioners contribute to the overall performance of V-belt systems. V-belt tensioners help maintain proper tension, prevent slippage, distribute the load evenly, and promote efficient power transmission. These characteristics are crucial for V-belt systems that require reliable and high-torque power transfer. Other types of belt tensioners, designed for different belt systems, may have different features and functions that cater to the specific requirements of those systems. The design of V-belt tensioners is optimized to enhance the performance and longevity of V-belt systems in their intended applications.

In summary, V-belt tensioners differ from other types of belt tensioners in terms of their design and application. They are specifically designed to work with V-belt systems, featuring pulleys with V-shaped grooves to accommodate the trapezoidal-shaped V-belts. V-belt tensioners incorporate adjustable arms or spring-loaded mechanisms to provide and maintain the necessary tension in the V-belt. They are primarily used in applications that require V-belts, such as automotive engines and industrial machinery. The design and application of V-belt tensioners are optimized to ensure proper tensioning, prevent slippage, distribute the load evenly, and enhance the performance of V-belt systems.

editor by CX 2023-12-29

China Best Sales High Quality Htd2600-8m Timing Belt for Industrial Machine axle assembly

Product Description

Product Description

Property

— Excellent dynamic curve performance

— Crack resistant

— CZPT resistant

— Anti-aging

— Heat resistant

— Wear resistant

Structure

Belt body: high quality synthetic CR rubber

Reinforcement: excellent quality fiberglass cord

Belt teeth: protected by highly wear resistant nylon elasticfabric

Double sided timing belt

Double sided timing belt can be divided into 2 types:

— DA with symmetrical teeth

— DB with staggered teeth

Timing belt sleeve

Height: 450mm

MOQ: 1 sleeve

Sleeve cutting machine is available

Specification

| T-toothed timing belt |

TYPE |

Pitch | Booth adge | Bottom tooth thickness |

Tooth height | Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | 2y° | s | hg | rr | ra | H | ||||

| MXL | 2.571 | 40 | 1.14 | 0.51 | 0.13 | 0.13 | 1.14 | 43~2044 | 87.38~4153.41 | |

| XXL | 3.175 | 50 | 1.73 | 0.76 | 0.20 | 0.20 | 1.52 | 46~124 | 146.05~393.70 | |

| XL | 5.085 | 2.57 | 1.27 | 0.38 | 0.38 | 2.3 | 22~510 | 111.76~2590.80 | ||

| L | 9.525 | 40 | 4.65 | 1.91 | 0.51 | 0.51 | 3.6 | 23~530 | 219.08~5048.25 | |

| H | 12.700 | 6.12 | 2.29 | 1.02 | 1.02 | 4.3 | 29~440 | 368.30~5588.00 | ||

| XH | 22.225 | 12.57 | 6.35 | 1.57 | 1.57 | 11.2 | 53~220 | 1177.93~4889.50 | ||

| XXH | 31.750 | 19.05 | 9.53 | 2.29 | 2.29 | 15.7 | 56~144 | 1778.00~4572.00 | ||

| T2.5 | 2.5 | 40 | 1.50 | 0.70 | 0.2 | 0.2 | 1.3 | 42~312 | 105.00~780.00 | |

| T5 | 5 | 2.65 | 1.20 | 0.4 | 0.4 | 2.2 | 30~400 | 150.00~2000.00 | ||

| T10 | 10 | 5.30 | 2.50 | 0.6 | 0.6 | 4.5 | 34~536 | 340.00~5360.00 | ||

| T20 | 20 | 10.15 | 5.00 | 0.8 | 0.8 | 8.0 | 61~181 | 1220.00~3620.00 |

|

HTD-toothed |

TYPE |

Pitch | Booth adge | Bottom tooth thickness |

Tooth height | Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | 2y° | s | hg | rr | ra | H | ||||

| 3M | 3 | 14 | 1.78 | 1.17 | 0.24-0.30 | 0.87 | 2.4 | 35~1000 | 105.00~3000.00 | |

| 5M | 5 | 3.05 | 2.06 | 0.40-0.44 | 1.49 | 3.8 | 35~852 | 175.00~4260.00 | ||

| 8M | 8 | 5.15 | 3.36 | 0.64-0.76 | 2.46 | 6.0 | 36~565 | 288.00~4520.00 | ||

| 14M | 14 | 9.40 | 6.02 | 1.20-1.35 | 4.50 | 10.0 | 56~340 | 784.00~4760.00 | ||

| 20M | 20 | 14.00 | 8.40 | 1.77-2.01 | 6.50 | 13.20 | 100~260 | 2000.00~5200.00 |

|

STPD/STS-toothed timing belt |

TYPE |

Pitch | Bottom tooth thickness |

Tooth height |

Fillet radius |

Fillet | Tip | Belt thickness |

teeth number range | Pitch length |

| Pb | s | hg | rbb | rr | ra | H | ||||

| S2M | 2 | 1.3 | 0.76 | 1.3 | 0.20 | 0.20 | 1.36 | 44~1914 | 88.00~3828.00 | |

| S3M | 3 | 1.95 | 1.14 | 1.95 | 0.30 | 0.30 | 1.94 | 41~500 | 123.00~1500.00 | |

| S4.5M | 4.5 | 2.93 | 1.71 | 2.93 | 0.45 | 0.45 | 2.81 | 40~201 | 180.00~904.50 | |

| S5M | 5 | 3.25 | 1.91 | 3.25 | 0.50 | 0.50 | 3.41 | 30~560 | 150.00~2800.00 | |

| S8M | 8 | 5.20 | 3.05 | 5.20 | 0.80 | 0.80 | 5.30 | 53~500 | 424.00~4000.00 | |

| S14M | 14 | 9.10 | 5.30 | 9.10 | 1.40 | 1.40 | 10.2 | 69~322 | 966.00~4508.00 |

|

RPP/HPPD-toothed timing belt |

TYPE |

Pitch | Bottom tooth thickness |

Tooth height | Belt thickness |

teeth number range | Pitch length |

| Pb | s | hg | H | ||||

| P2M | 2 | 1.30 | 0.73 | 1.3 | 56~612 | 112.00~1224.00 | |

| P3M | 3 | 1.95 | 1.09 | 2.1 | 30~621 | 90.00~1863.00 | |

| P5M | 5 | 3.25 | 1.81 | 3.6 | 36~400 | 180.00~2000.00 | |

| P8M | 8 | 5.20 | 2.90 | 5.5 | 40~550 | 320.00~4400.00 | |

| P14M | 14 | 9.50 | 6.00 | 10.0 | 69~327 | 966.00~4578.00 |

Applications

Company Information

FAQ

Q1.Can I have a sample order for Timing belt?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

1) 2–3 days for sample

2) 20–30 days for mass production. If urgent,we have green channel.

Q3. Do you have any MOQ limit for V belt order?

Low MOQ, 1pc for sample checking is available

Q4. Is it OK to print my logo on V belt product?

Yes. Please inform us your logo or design before mass production

Q5. How to guarantee your quality? We are 1 of the top suppliers of International famous Belt company over years. Excellent quality is well accepted.

Please contact us for more details. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there specific considerations for choosing V-belt tensioners in applications with varying loads or environmental conditions?

When selecting V-belt tensioners for applications with varying loads or environmental conditions, several specific considerations come into play. The dynamic nature of load changes and the presence of challenging environmental factors can significantly impact the performance and reliability of the tensioners. Here’s a detailed explanation of the specific considerations for choosing V-belt tensioners in such applications:

- Load Variation:

- Adjustability: Look for tensioners that offer adjustability, such as those with slotted mounting holes or adjustable arms. This allows for easy tension adjustment to accommodate load variations and maintain the proper belt tension.

- Spring-Loaded Tensioners: Spring-loaded tensioners are particularly useful in applications with load fluctuations. The spring mechanism automatically adjusts the tension to compensate for belt elongation or changes in load, ensuring consistent tension and minimizing belt slippage.

- Multi-Tensioner Systems: In applications with significant load variations, employing multiple tensioners strategically positioned along the belt path can help distribute the tension more evenly. This ensures that each section of the belt receives the appropriate tension, reducing the risk of belt slippage and optimizing power transmission.

- Environmental Conditions:

- Corrosion Resistance: In corrosive environments, such as those with high humidity or exposure to chemicals, choose tensioners with corrosion-resistant materials or coatings. Stainless steel or materials with zinc or chrome plating provide effective protection against corrosion.

- Temperature Resistance: Extreme temperatures can affect the mechanical properties of tensioners. Ensure that the chosen tensioners can withstand the temperature range of the application without compromising their performance or structural integrity.

- Contaminant Resistance: Some applications may involve the presence of contaminants like dust, dirt, or debris. Tensioners with sealed bearings or protective covers can help prevent the ingress of contaminants, minimizing the risk of damage and ensuring smooth operation.

- Weatherproofing: In outdoor applications exposed to weather elements, consider tensioners with weatherproof features or additional protective measures to prevent water or moisture ingress and maintain reliable performance.

- System Monitoring and Maintenance:

- Periodic Inspection: Implement a regular inspection schedule to check the condition of the tensioners, belts, and pulleys. Look for signs of wear, misalignment, or damage, and address any issues promptly.

- Belt Tension Measurement: Utilize belt tension measurement tools to monitor and verify the tension levels. Adjust the tension as needed to accommodate load variations and maintain optimal belt performance.

- Lubrication: If the tensioners have moving parts or bearings, ensure proper lubrication as per the manufacturer’s recommendations. This helps to reduce friction, minimize wear, and extend the life of the tensioners.

- Record Keeping: Maintain records of maintenance activities, including tension adjustments, inspections, and replacements. This facilitates tracking the performance of the tensioners over time and aids in identifying any recurring issues.

In applications with varying loads, it’s essential to choose tensioners that can adapt to these changes and maintain optimal belt tension. Considerations include:

Environmental conditions can have a substantial impact on the performance and longevity of V-belt tensioners. Considerations include:

In applications with varying loads or challenging environmental conditions, proactive monitoring and regular maintenance are crucial to ensure optimal performance. Consider the following:

By considering these specific factors when choosing V-belt tensioners for applications with varying loads or environmental conditions, you can ensure that the selected tensioners are capable of adapting to load changes, withstand challenging environments, and provide reliable and long-lasting performance. Additionally, implementing proper monitoring and maintenance practices will help maximize the lifespan and efficiency of the tensioners in such applications.

What are the common signs of improper V-belt tension, and how can tensioners address these issues?

Improper V-belt tension can lead to various issues in power transmission systems. Recognizing the signs of improper tension is essential for ensuring efficient and reliable operation. V-belt tensioners play a crucial role in addressing these issues. Here’s a detailed explanation of the common signs of improper V-belt tension and how tensioners can address them:

- Slippage:

- Belt Wear and Damage:

- Noise and Vibrations:

- Uneven Belt Tracking:

- Reduced Power Transmission Efficiency:

One of the most noticeable signs of improper V-belt tension is slippage. Slippage occurs when the belts fail to maintain proper grip on the pulleys, resulting in power transmission inefficiencies. If you observe the belts slipping or hear squealing noises during operation, it indicates inadequate tension. Tensioners can address this issue by applying the correct tension force to the belts, ensuring they maintain sufficient grip on the pulleys and eliminating slippage.

Improper V-belt tension can cause accelerated wear and damage to the belts. Under-tensioning can lead to excessive flexing and bending, resulting in increased wear. Over-tensioning can put excessive stress on the belts, leading to premature failure. Signs of improper tension-related wear include fraying, cracking, or glazing on the belt surface. Tensioners can address this issue by maintaining the optimal tension level, minimizing wear-inducing bending and flexing, and preventing excessive stress on the belts.

Incorrect V-belt tension can cause excessive noise and vibrations in the system. Under-tensioned belts may produce a rattling or vibrating sound, indicating inadequate grip and power transmission inefficiency. Over-tensioned belts can generate excessive tension-related vibrations, leading to noise and potential damage. Tensioners can address this issue by applying the correct tension force, ensuring smooth and quiet operation by reducing belt movement and vibrations.

Improper tension can cause uneven belt tracking, where the belts shift or wander off-center on the pulleys. This can result in belt misalignment, increased friction, and accelerated wear. Signs of uneven belt tracking include belts running close to the edges of the pulleys or rubbing against adjacent components. Tensioners can address this issue by maintaining proper tension, keeping the belts aligned with the pulleys, and preventing misalignment-induced wear and damage.

Incorrect V-belt tension can lead to reduced power transmission efficiency. Under-tensioning causes slippage and loss of power, resulting in decreased system performance. Over-tensioning increases friction and strain, leading to energy losses and reduced efficiency. Tensioners can address this issue by applying the optimal tension force, maximizing power transfer efficiency, and minimizing energy losses due to slippage or excessive friction.

It’s important to periodically inspect V-belt tension and address any signs of improper tension promptly. Tensioners provide the means to adjust and maintain the correct tension level, ensuring efficient and reliable power transmission. By addressing issues such as slippage, belt wear, noise and vibrations, uneven belt tracking, and reduced power transmission efficiency, tensioners help optimize the performance and lifespan of V-belt systems.

In what industries and machinery are V-belt tensioners commonly used for optimal belt functionality?

V-belt tensioners are commonly used in various industries and machinery where optimal belt functionality is essential. The design and characteristics of V-belts make them suitable for applications that require high torque transmission, durability, and reliable power transfer. Here’s a detailed explanation of the industries and machinery where V-belt tensioners are commonly used:

- Automotive Industry:

- Industrial Machinery:

- HVAC Systems:

- Power Generation:

- Agricultural Machinery:

The automotive industry is one of the primary sectors where V-belt tensioners are commonly utilized. V-belts are used in automotive engines to drive various components such as the alternator, water pump, power steering pump, and air conditioning compressor. V-belt tensioners ensure proper tensioning of the belts, allowing for efficient power transmission and reliable operation of these critical automotive systems.

V-belt tensioners find extensive use in a wide range of industrial machinery and equipment. Industries such as manufacturing, mining, agriculture, construction, and material handling rely on V-belt-driven systems for power transmission. V-belts are commonly found in machinery such as conveyor systems, pumps, compressors, fans, blowers, and generators. V-belt tensioners play a crucial role in maintaining optimal tension, preventing belt slippage, and ensuring reliable and efficient operation of these industrial systems.

Heating, ventilation, and air conditioning (HVAC) systems often incorporate V-belt-driven components. V-belt tensioners are used to ensure proper tensioning of the belts in HVAC systems, which may include components like HVAC fans, blowers, and pumps. The tensioners help maintain reliable power transmission, prevent belt slippage, and ensure efficient operation of the HVAC equipment, contributing to effective climate control in various settings such as commercial buildings, residential complexes, and industrial facilities.

In power generation facilities, V-belt tensioners are commonly employed in equipment such as generators and turbines. V-belts are used to transmit power from the prime mover to the generator or turbine, and the tensioners ensure proper belt tension to maintain efficient power transfer. V-belt tensioners play a vital role in power generation applications, helping to optimize performance, prevent belt slippage, and ensure reliable operation of the power generation equipment.

Agricultural machinery and equipment, including tractors, combines, and agricultural implements, often rely on V-belt-driven systems. V-belts are used to transfer power to various agricultural components such as grain augers, hay balers, and irrigation pumps. V-belt tensioners in agricultural machinery help maintain the proper tension in the belts, ensuring efficient power transmission and reliable operation in demanding agricultural environments.

V-belt tensioners are also utilized in other industries and machinery such as marine applications (e.g., marine engines and propulsion systems), construction equipment (e.g., concrete mixers and excavators), and woodworking machinery (e.g., saws and planers). These tensioners are designed to accommodate the specific requirements of each industry and application, ensuring optimal belt functionality, reliable power transmission, and extended belt life.

editor by CX 2023-12-25

China Best Sales INJ – Mill Machine Belt Multiple V-Ribbed Belt And Timing Belt axle arm

Product Description

Company Profile

ZHangZhoug INJ transmission systems Co.,ltd located in HangZhou, ZHangZhoug province,was founded in 2003. We are a professional supplier of domestic and imported transmission belts. We have good experience and technology in stone\ceramic\wood\textiles\tobacco\logistics\firecrackers\medicine\glass\steel\automotive\electronics\beverages\spices\paper\printing\cable. Welcome all customers to contact us any time to investigate and negotiate.

Raw Materials

Belt: High-quality neoprene (CR)as the main raw materials( imported from Japan)

Skeleton materials: Glass Fiber(imported from Janpan)

Tooth surface: Nylon 66 high

Product Features

*1: High-efficiency factor and extreme tensile strength

*2: Extraordinarily resistance on cold & heat (-40ºC-120ºC), oil and ozone

*3: Excellent aging-resistance and abrasion-resistance

*4: Slip-free transmission and low noise

Product Description

| TYPE | SUPPLY CHARACTERISTIC |

| MXL XXL XL L H XH XXHT 2.5 T5 T10 T20 AT5 AT10 AT 20 HTD:2M 3M 5M 8M 14M 20M STS:S2M S3M S4.5M S5M S8M S14M RPP:RP2M RP3M RP5M RP8M RP14M |

1. Company leading products with more than 4000 moulds. 2. Cutting or provide sleeve according to customer’s requirement. 3. Anti-static, oil, heat-resistant,low temperature resistance ect. |

Property of Timing Belt

| Test Item | Test Result |

| Tension strength (≥KN/25.4mm) | 0.59-10.8 (according to types) |

| Elongation (≤ % ) | 4.0 (all types) |

| Loading (KN/25.4mm) | 0.49-8.64 (according to types) |

Trapezoidal Tooth Profile

Curvilinear Tooth Profile

Curvilinear Tooth Profile

| Gear code | Type | Pitch(mm) | Tooth height(mm) | Belt thickness(mm) |

| HTD | 3M | 3 | 1.22 | 2.40 |

| 5M | 5 | 2.06 | 3.80 | |

| 8M | 8 | 3.36 | 6.00 | |

| 14M | 14 | 6.02 | 10.00 | |

| 20M | 20 | 8.40 | 13.20 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 1.90 | |

| S4.5M | 4.5 | 1.71 | 2.81 | |

| S5M | 5 | 1.91 | 3.40 | |

| S8M | 8 | 3.05 | 5.30 | |

| S14M | 14 | 5.30 | 10.20 | |

| RPP/HPPD | P2M | 2 | 0.76 | 1.36 |

| P3M | 3 | 1.15 | 1.90 | |

| P5M | 5 | 1.95 | 3.50 | |

| P8M | 8 | 3.20 | 5.50 | |

| P14M | 14 | 6.00 | 10.0 |

T type Industrial Timing Belt

| Type | Pitch(mm) | Tooth height(mm) | Belt thickness(mm) | Angle ° |

| MXL | 2.032 | 0.51 | 1.14 | 40 |

| XXL | 3.175 | 0.76 | 1.52 | 50 |

| XL | 5.080 | 1.27 | 2.30 | 50 |

| L | 9.525 | 1.91 | 3.60 | 40 |

| H | 12.70 | 2.29 | 4.30 | 40 |

| XH | 22.225 | 6.35 | 11.20 | 40 |

| XXH | 31.750 | 9.53 | 15.70 | 40 |

| T2.5 | 2.5 | 0.7 | 1.30 | 40 |

| T5 | 5 | 1.2 | 2.20 | 40 |

| T10 | 10 | 2.50 | 4.50 | 40 |

| T20 | 20 | 5.00 | 8.00 | 40 |

| AT5 | 5 | 1.20 | 2.70 | 50 |

| AT10 | 10 | 2.50 | 5.00 | 50 |

| AT20 | 20 | 5.00 | 8.00 | 50 |

Buyer Notice

1. The price is subject to the company’s actual quotation!

2. All products are strictly inspected by our company before shipment to ensure that they are shipped without problems.

3. The pictures are all taken in kind, but there will be slight chromatic aberration due to light and display, etc. Please understand.

4. Before placing an order or before purchasing, please consult the product model, specifications, etc. so that we can confirm whether the product you need is in stock.

1. Could you offer the sample for testing?

RE: If you need sample, pls contact us soon. about the sample charge, we can consult it.

2. How about the delivery date?

RE: The delivery date is depended on your quantity. Small order is about 5 days, big order 20 days.

3. Do you set the MOQ and give any discount?

RE:We do not set the MOQ. But the more you place, the more discount you will get.

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery, Car |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Nylon |

| Type: | Toothed Belt |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What role do materials and coatings play in the performance and longevity of V-belt tensioners?

Materials and coatings play a significant role in the performance and longevity of V-belt tensioners. The choice of materials and the application of appropriate coatings can greatly impact the durability, reliability, and overall effectiveness of the tensioners. Here’s a detailed explanation of the role materials and coatings play in the performance and longevity of V-belt tensioners:

- Material Selection:

- Coatings:

- Zinc or Chrome Plating: These coatings provide excellent corrosion resistance, protecting the tensioner from environmental factors, such as moisture and chemicals. They also enhance the aesthetic appearance of the tensioner.

- Powder Coating: Powder coating is a durable and long-lasting coating option that provides corrosion resistance and improved wear resistance. It can also offer a variety of color options to match specific design requirements.

- Teflon or PTFE Coating: Teflon or PTFE (Polytetrafluoroethylene) coatings offer low friction properties, reducing wear and extending the life of the tensioner. These coatings are particularly useful in applications where minimizing friction and energy losses are critical.

- Ceramic Coating: Ceramic coatings provide excellent hardness and wear resistance. They are often used in high-performance applications where the tensioner is subjected to severe wear and abrasive conditions.

- Benefits for Performance and Longevity:

- Increased Wear Resistance: High-quality materials and coatings can significantly improve the wear resistance of tensioners, reducing the rate of wear and extending their service life. This is particularly important in applications with high belt speeds, heavy loads, or abrasive environments.

- Enhanced Corrosion Protection: Coatings, such as zinc or chrome plating, provide effective corrosion protection, preventing rust and degradation of the tensioner in humid or corrosive environments.

- Reduced Friction: Coatings, such as Teflon or PTFE, reduce friction between the tensioner and the belt, minimizing heat generation and energy losses. This improves the efficiency of the V-belt system and reduces wear on both the tensioner and the belt.

- Improved Surface Hardness: Coatings, such as ceramic coatings, enhance the surface hardness of tensioners, making them more resistant to wear and abrasion. This results in longer-lasting tensioners that can withstand demanding operating conditions.

The selection of materials for V-belt tensioners is crucial as they need to withstand the demanding operating conditions encountered in V-belt systems. High-quality materials with excellent mechanical properties, such as strength, hardness, and wear resistance, are typically chosen. Common materials used for tensioners include metals, such as steel or cast iron, and advanced polymers, such as thermoplastics or thermosetting plastics.

Metal tensioners offer high strength and rigidity, making them suitable for heavy-duty applications with high tension loads. They are also resistant to temperature variations and provide stability under demanding conditions. Polymer tensioners, on the other hand, offer advantages such as lightweight, corrosion resistance, and reduced noise and vibration transmission. The choice between metal and polymer materials depends on the specific requirements of the V-belt system and the operating environment.

Coatings are often applied to the surfaces of V-belt tensioners to enhance their performance and extend their longevity. Coatings provide several benefits, such as improved wear resistance, corrosion protection, reduced friction, and enhanced surface hardness. Here are some commonly used coatings for V-belt tensioners:

The choice of materials and coatings in V-belt tensioners directly impacts their performance and longevity. Here are the key benefits they provide:

In summary, materials and coatings play a vital role in the performance and longevity of V-belt tensioners. The selection of high-quality materials and appropriate coatings ensures that tensioners can withstand the rigors of V-belt systems, resist wear and corrosion, reduce friction, and maintain their effectiveness over an extended service life. Considering the specific requirements of the application and the operating environment, manufacturers choose materials and coatings that optimize the performance and longevity of V-belt tensioners, ultimately contributing to the reliable operation of the V-belt system.

How do V-belt tensioners contribute to reducing wear and increasing the efficiency of power transmission?

V-belt tensioners play a crucial role in reducing wear and increasing the efficiency of power transmission in V-belt systems. Their primary function is to maintain the proper tension in the V-belts, which has several benefits. Here’s a detailed explanation of how V-belt tensioners contribute to reducing wear and increasing power transmission efficiency:

- Preventing Slippage:

- Reducing Belt Wear:

- Minimizing Belt Stretching:

- Improving Belt Alignment:

- Optimizing Belt Engagement:

V-belt tensioners ensure that the V-belts maintain sufficient grip on the pulleys. Proper tensioning prevents slippage, especially under high loads or during sudden changes in speed or torque. Slippage not only reduces the efficiency of power transmission but also leads to accelerated wear of the belts and pulleys. By maintaining the correct tension, tensioners minimize slippage, ensuring efficient power transfer and reducing wear on the V-belts.

Optimal tensioning helps reduce wear on V-belts. When V-belts are under-tensioned, they can experience excessive bending and flexing, leading to increased wear. Over-tensioning, on the other hand, can put excessive stress on the belts, causing premature wear. V-belt tensioners ensure that the belts are properly tensioned, minimizing bending, flexing, and stress. This reduces wear on the belts, extends their lifespan, and improves overall system reliability.

Correct tensioning helps minimize stretching of V-belts. When V-belts are under-tensioned, they can elongate and lose their original shape. This stretching can lead to reduced contact area with the pulleys, resulting in decreased power transmission efficiency and increased wear. V-belt tensioners maintain the optimal tension level, minimizing stretching and ensuring that the belts remain in their designed shape. This promotes efficient power transmission and prolongs the lifespan of the V-belts.

V-belt tensioners contribute to proper belt alignment, which is crucial for efficient power transmission. When V-belts are under-tensioned or over-tensioned, they can become misaligned on the pulleys. Misalignment causes uneven belt wear, increased friction, and potential belt damage. Tensioners help maintain proper belt alignment by applying the correct tension force. This ensures that the belts remain aligned with the pulleys, reducing stress, minimizing wear, and improving power transmission efficiency.

Correct tensioning ensures optimal engagement of V-belts with the pulleys. When V-belts are properly tensioned, they maintain the desired depth of engagement in the pulley grooves. This maximizes the contact area between the belts and the pulleys, enhancing power transmission efficiency. Proper tensioning also helps prevent belt slip, which can occur when the belts are not properly engaged with the pulleys. By optimizing belt engagement, tensioners contribute to efficient power transmission and minimize wear on the V-belts.

In summary, V-belt tensioners are essential in reducing wear and increasing the efficiency of power transmission. They prevent slippage, reduce belt wear and stretching, improve belt alignment, and optimize belt engagement. By maintaining the correct tension in V-belt systems, tensioners minimize power losses, extend the lifespan of the belts, and enhance the overall efficiency and reliability of the power transmission system.

Can you explain the significance of proper tensioning in V-belt-driven machinery and equipment?

Proper tensioning plays a significant role in V-belt-driven machinery and equipment. It is crucial for ensuring efficient power transmission, preventing slippage, and maximizing the performance and reliability of the V-belt system. Here’s a detailed explanation of the significance of proper tensioning in V-belt-driven machinery and equipment:

- Efficient Power Transmission:

- Preventing Slippage:

- Extending Belt Life:

- Reducing Maintenance and Downtime:

- Enhancing System Reliability:

Proper tensioning is essential for efficient power transmission in V-belt-driven systems. When the V-belt is properly tensioned, it maintains a firm grip on the pulleys, allowing for effective transfer of rotational energy from the driving pulley to the driven components. The correct tension ensures that power is transmitted without slippage, minimizing energy losses and maximizing the system’s efficiency. By maintaining proper tension, V-belt-driven machinery and equipment can achieve optimal power transfer and operate at their intended speeds and performance levels.

One of the primary purposes of proper tensioning is to prevent slippage between the V-belt and the pulleys. Slippage can occur when the tension in the V-belt is inadequate or when the belt is subjected to excessive loads. Insufficient tension or overloading can cause the belt to lose traction with the pulleys, resulting in reduced power transmission, decreased efficiency, and potential damage to the belt and other system components. Proper tensioning ensures that the V-belt remains tightly engaged with the pulleys, preventing slippage and maintaining reliable power transmission.

Proper tensioning is essential for extending the life of the V-belt. When a V-belt is under excessive tension, it can experience accelerated wear and premature failure due to increased stress on the belt and the pulleys. On the other hand, insufficient tension can lead to belt vibration, excessive flexing, and localized wear, reducing the belt’s lifespan. By maintaining the correct tension, V-belt-driven machinery and equipment can minimize wear, distribute the load evenly across the belt and pulleys, and promote optimal belt life. Proper tensioning contributes to reducing maintenance costs and downtime associated with belt replacement.

Proper tensioning helps reduce maintenance requirements and downtime in V-belt-driven systems. When the V-belt is under the correct tension, it operates smoothly without slippage or excessive wear. This minimizes the need for frequent adjustments, re-tensioning, and belt replacements. By maintaining the proper tension, V-belt-driven machinery and equipment can operate reliably, with reduced risks of unexpected belt failures or performance issues. Proper tensioning contributes to increased system uptime, improved productivity, and reduced maintenance costs.

Proper tensioning enhances the overall reliability of V-belt-driven machinery and equipment. When the V-belt is correctly tensioned, it operates within its designed parameters, ensuring that the system components are subjected to the appropriate forces and loads. This reduces the risk of belt slippage, excessive wear, and premature component failure. By promoting reliable power transmission, minimizing the potential for system malfunctions, and extending the lifespan of the V-belt and other system components, proper tensioning contributes to the overall reliability and longevity of V-belt-driven machinery and equipment.

In summary, proper tensioning is of significant importance in V-belt-driven machinery and equipment. It ensures efficient power transmission, prevents slippage, extends the life of the V-belt, reduces maintenance requirements and downtime, and enhances the overall reliability of the system. By maintaining the correct tension, V-belt-driven machinery and equipment can achieve optimal performance, maximize energy efficiency, and minimize the risks of belt failure or system malfunctions.

editor by CX 2023-11-30

China OEM CZPT Machine Part V-Grooved Pulley (04508063) for (BF1013) engine pulley

Product Description

Company profile

As the main and big supplier & manufacturer of CZPT engine parts in China . we can provide parts for CZPT 912/913/914/1013/2012/2013/1011/2011/413/513/1015/226B series engines .

we have our own technology to develop and produce the CZPT fuel pump , coolant pump , shutdown device , 1011/2011 timing belt kit & oil pump .

High quality & larger inventory & competitive price are our advantages .

Parts List

Photos of our Products :

Photos of our others parts

Packages for shipping

| Certification: | ISO9001 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Iron |

| Type: | V-Grooved Pulley |

| Quality: | High Quality |

Calculate the ideal mechanical advantage of pulleys

The basic equations for pulleys can be found in this article. It will also cover the different types of pulleys, the ideal mechanical advantages of pulleys, and some common uses of pulley systems. Read on to learn more! After all, a pulley is a simple mechanical device that changes the direction of a force. Learn more about pulleys and their common uses in engineering.

pulley basic equation

Pulleys work the same way as gravity, so they should withstand similar forces. Newton’s laws of motion can be used to calculate the forces in a pulley system. The second law of motion applies to forces and accelerations. Similar to this is Newton’s third law, which states that the directions of forces are equal and opposite. The fourth law dictates the direction of force. The Fifth Law states that tension is in equilibrium with gravity.

A pulley is a simple mechanism that transmits force by changing direction. They are generally considered to have negligible mass and friction, but this is only an approximation. Pulleys have different uses, from sailboats to farms and large construction cranes. In fact, they are the most versatile mechanisms in any system. Some of their most common applications and equations are listed below.

For example, consider two masses m. Those of mass m will be connected by pulleys. The static friction coefficient of the left stop is ms1, and the static friction coefficient of the right stop is ms2. A no-slip equation will contain multiple inequalities. If the two blocks are considered to be connected by a pulley, the coefficient of kinetic friction is mk. In other words, the weight of each block carries the same mass, but in the opposite direction.

Types of pulleys

A pulley is a device used to pull and push objects. Pulley systems are ropes, cables, belts or chains. The “drive pulley” is attached to the shaft and moves the driven pulley. They are available in a variety of sizes, and the larger they are, the higher the speed of power transmission. Alternatively, use small pulleys for smaller applications.

Two-wheel pulleys have two mechanical advantages. The greater the mechanical advantage, the less force is required to move the object. More wheels lift more weight, but smaller pulleys require less force. In a two-wheel pulley system, the rope is wound around two axles and a fixed surface. As you pull on the rope, the shafts above slowly come together.

Compound pulleys have two or more rope segments that are pulled up on the load. The mechanical advantage of compound pulleys depends on the number of rope segments and how they are arranged. This type of pulley can increase the force by changing the direction of the rope segment. There are two main types of pulleys. Composite pulleys are most commonly used in construction. The ideal mechanical advantage of pulleys is 2 or more.

Construction pulleys are a basic type. They are usually attached to wheel rails and can be lifted to great heights. Combinations of axes are also common. Construction pulleys can be raised to great heights to access materials or equipment. When used in construction, these pulleys are usually made of heavy materials such as wood or metal. They are secured with ropes or chains.

The ideal mechanical advantage of pulleys

The pulley system is a highly complex system with high mechanical advantages. Use a single pulley system to reduce the force required to lift an object by cutting it in half. The mechanical advantage increases as you add more pulleys, such as six or seven. To calculate the mechanical advantage of a pulley system, you need to count the number of rope segments between the pulleys. If the free end of the rope is facing down, don’t count it. If it’s facing up, count. Once you have your number, add it up.

The required mechanical advantage of a pulley is the number of rope segments it has to pull the load. The more rope segments, the lower the force. Therefore, the more rope segments the pulley has, the lower the force. If the rope segments are four, then the ideal mechanical advantage is four. In this case, the composite pulley quadrupled the load force.

The ideal mechanical advantage of a pulley system is the sum of the mechanical force and the force required to lift the load at its output. Typically, a single pulley system uses two ropes, and the mechanical force required to lift the load is multiplied by the two ropes. For a multi-pulley system, the number of ropes will vary, but the total energy requirement will remain the same. The friction between the rope and pulley increases the force and energy required to lift the load, so the mechanical advantage diminishes over time.

Common uses of pulley systems

A pulley system is a simple mechanical device typically used to lift heavy objects. It consists of a rotating wheel attached to a fixed shaft and a rope attached to it. When the wheel moves, the force applied by the operator is multiplied by the speed of the pulley, and the force is multiplied by the weight of the object being lifted. Common uses for pulley systems include pulling, lifting, and moving heavy objects.

The oil and petroleum industries use pulley systems in a variety of applications. Most commonly, pulleys are used in drilling operations and they are installed on top of the rig to guide the cable. The cable itself is attached to two pulleys suspended in the derrick, where they provide mechanical energy to the cable. Using a pulley system in this application provides the force needed to move the cable safely and smoothly.

The main advantage of the pulley system is that it minimizes the force required to lift an object. The force used to lift the object is multiplied by the desired mechanical advantage. The more rope segments, the lower the force required. On the other hand, a compound pulley system can have many segments. Therefore, a compound pulley system can increase the force a worker can exert on an object.

Safety Precautions to Take When Working on Pulley Systems

There are many safety precautions that should be observed when working on a pulley system. The first is to wear proper protective gear. This includes hard hats that protect you from falling objects. Also, gloves may be required. You should limit the amount of movement in the penalty area, and you should also keep the area free of unnecessary people and objects. Also, remember to wear a hard hat when working on the pulley system.

Another important safety precaution when working on a pulley system is to check the Safe Working Load (SWL) of the pulley before attaching anything. This will help you understand the maximum weight the pulley can hold. Also, consider the angle and height of the pulley system. Always use safety anchors and always remember to wear a hat when working on a pulley system.

Safe use of chain hoists requires training and experience. It is important to read the manufacturer’s manual and follow all safety precautions. If you’re not sure, you can actually inspect the hoist and look for signs of damage or tampering. Look for certifications for sprocket sets and other lifting accessories. Look for the Safe Working Load (SWL) marking on the chain hoist.

Example of a pulley system

Pulley systems are often used to lift items. It allows you to reduce the effort to lift and move the load by applying force in one direction. Pulley systems can be built and modeled to fit any type of project. This resource focuses on pulley systems and is designed to support the new GCSEs in Engineering, Design and Technology. There are also many examples of pulley systems suitable for various applications.

In the study, participants who read easy text took longer to manipulate the pulley system than those who read challenging text. In general, this suggests that participants with prior scientific experience used their cognitive abilities more effectively. Additionally, students who read simple texts spent less time planning the pulley system and more time on other tasks. However, the study did show that the time required to plan the pulley system was similar between the two groups.