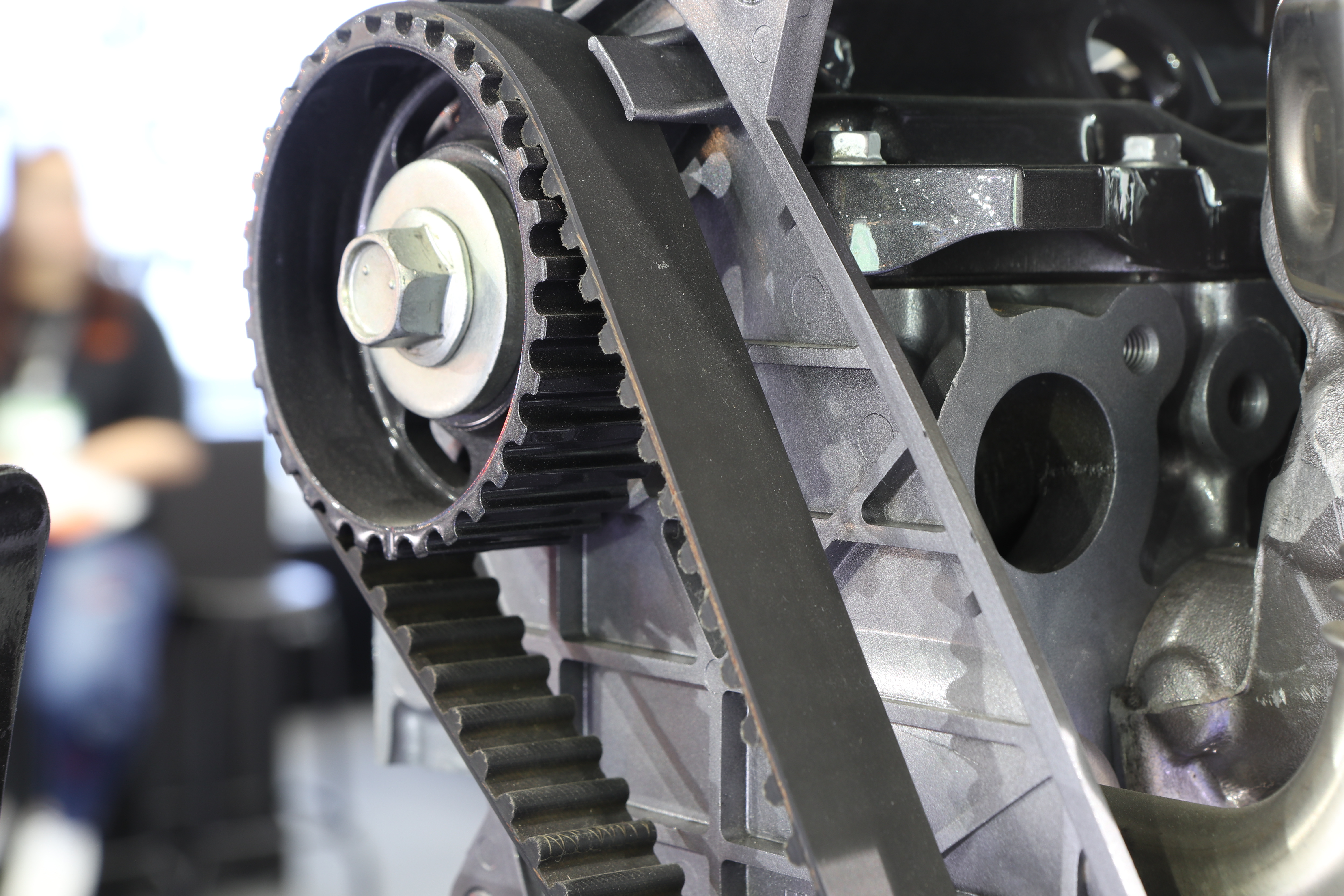

Product Description

We are China’s leading manufacturer and exporter of timing pulleys and timing pulley rods, with more than 20 years of export experience in the field of power transmission components

1. Material: C45 steel, aluminum, brass, Cat Iron, nylon, POM, etc.

2. Surface treatment: black oxidation, phosphating, anodic oxidation, nickel plating, zinc plating, etc.

3. Tooth shape: H, XH, XXH; L, XL, MXL; T2.5, T5, T10, T20;

HTD/STD 3M, 5M, 8M, 14M; AT5, AT10, AT20; 3MR, 5MR; S5M, S8M; RPP5, RPP8, etc.

4. Hole: pilot hole, taper hole.

5. Equipment: gear hobbing machine, drilling machine, machining center, CNC machine tool, milling machine, gear shaper, grinder, etc.

6. Tolerance: According to customer requirements.

7. OEM and ODM orders are also welcome.

So far, our timing belt pulleys have been exported to Europe, North America, Southeast Asia and the Middle East markets, etc., and have established long-term cooperative relations. We guarantee to provide high-quality products at very competitive prices in China. In addition, we can provide services such as product customization, process optimization, quality control and logistics.

Company Profile

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

Related Products

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering : Machine Tools, Foundry Equipments, Conveyors, Compressors, Painting systems etc.

2. Pharmaceuticals & Food Processing : Pulp Mill Blowers, Conveyor in warehouse, Agitators, Grain, Boiler, Bakery Machine, Labeling Machine, Robots etc.

3. Agriculture Industries : Cultivator, Rice Winnower Tractor, Harvester, Harvester, Rice Planter etc

4. Textile Mills : Looms, Spinning, Wrappers, High-speed auto looms, Processing machine, Twister, Carding machine. Ruler calendar machine high speed winder etc.

5. Printing Machinery : News paper press, Rotary machine, Screen Printer Machine, Linotype machine offset printer etc.

6. Paper Industries : Chipper roll grinder, Cut off saw, Edgers, Flotation cell and chips saws etc.

7. Building Construction Machinery : Buffers, Elevator Floor polisher mixing machine, vibrator, Hoists, Crusher etc.

8.Office Equipments : Typewriter, Plotters, Camera, Money drive, Money Sorting machine, Data storage equipment etc.

9.Glass and plastic Industries : Conveyor, Carton Sealers, Grinders, Creeper paper manufacturing machine, Lintec backing etc.

10.Home Appliances : Vacuum cleaner, Laundry machine, iceream machine, Sewing Machine, Kitchen equipments etc.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Food Machinery, Agricultural Machinery |

| Surface Treatment: | Anodize, Black Oxide, Phosphate and Galvanizat |

| Material: | Aluminum, Steel, Cast Iron |

| Color: | Any Color |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the reliability and durability aspects of V-belt tensioners in ensuring consistent tension?

V-belt tensioners play a crucial role in ensuring consistent tension in V-belt systems. Reliability and durability are essential aspects of V-belt tensioners that contribute to their ability to maintain consistent tension over time. Here’s a detailed explanation of the reliability and durability aspects of V-belt tensioners in ensuring consistent tension:

- Construction Materials:

- Design and Engineering:

- Bearing Systems:

- Wear and Fatigue Resistance:

- Environmental Resistance:

The choice of construction materials significantly affects the reliability and durability of V-belt tensioners. High-quality materials with excellent strength, wear resistance, and corrosion resistance are essential for long-term performance. Common materials used in tensioner construction include robust metals, advanced polymers, and specialized alloys. These materials ensure that the tensioner can withstand the forces and operating conditions encountered in V-belt systems, such as high loads, belt tension, temperature variations, and exposure to contaminants.

The design and engineering of V-belt tensioners are critical factors in their reliability and durability. Tensioners should be designed to distribute loads evenly, minimize stress concentrations, and provide smooth operation. Advanced engineering techniques, such as finite element analysis, are employed to optimize the design and ensure structural integrity. Additionally, attention to detail in the design process helps to minimize potential failure points, improve load-carrying capacity, and enhance overall performance.

The bearing systems within V-belt tensioners are crucial for their reliable operation. High-quality bearings, such as ball bearings or roller bearings, are used to support the rotating components and withstand the radial and axial loads. Proper bearing selection, lubrication, and sealing mechanisms are essential to ensure smooth rotation, minimize friction, and prevent premature wear. Reliable bearing systems contribute to the consistent performance of the tensioner and help maintain the desired tension in the V-belt system.

V-belt tensioners are subjected to continuous cyclic loads and motion, which can lead to wear and fatigue over time. To ensure durability and reliability, tensioners are designed and constructed to resist wear and fatigue. This may involve the use of wear-resistant coatings, hardened surfaces, or specialized materials that can withstand repetitive loading without deformation or failure. By incorporating wear and fatigue-resistant features, tensioners can maintain their performance and tensioning capabilities over an extended service life.

V-belt tensioners often operate in diverse environmental conditions, including temperature extremes, humidity, dust, and chemical exposure. Reliable tensioners are designed to withstand these environmental factors and provide consistent tension regardless of the operating environment. Protective coatings, seals, and corrosion-resistant materials are employed to prevent damage from contaminants or chemical exposure. By ensuring environmental resistance, tensioners can maintain their functionality and performance, thereby ensuring consistent tension in V-belt systems.

In summary, the reliability and durability of V-belt tensioners are crucial aspects in ensuring consistent tension in V-belt systems. Construction materials, design and engineering, bearing systems, wear and fatigue resistance, and environmental resistance all contribute to the long-term performance and reliability of tensioners. By selecting high-quality tensioners that are designed and constructed to withstand the demands of V-belt applications, users can have confidence in the consistent tensioning capabilities of the tensioner, leading to reliable and efficient operation of the V-belt system.

Can you provide guidance on selecting and sizing V-belt tensioners for specific V-belt applications?

Yes, selecting and sizing V-belt tensioners for specific V-belt applications requires careful consideration of various factors. Here’s a detailed guidance on how to select and size V-belt tensioners:

- Understand the Application Requirements:

- Determine the Tensioning Force:

- Consider Belt Type and Size:

- Assess Space Constraints and Mounting Options:

- Consider Environmental Factors:

- Consult Manufacturer Specifications and Guidelines:

- Consider Maintenance and Serviceability:

- Consider Cost and Long-Term Value:

Begin by understanding the specific requirements of the V-belt application. Consider factors such as the power transmission requirements, load conditions, operating speed, and environmental conditions. This information will help determine the appropriate tension force and other specifications needed for the tensioner.

Calculate the required tensioning force for the V-belt system. The tensioning force depends on factors such as the power being transmitted, the coefficient of friction between the belt and pulleys, and the belt’s characteristics. Manufacturers typically provide tension force guidelines based on belt type and application. Ensure that the selected tensioner can provide the required tensioning force within the desired operating range.

Take into account the type and size of the V-belt being used. Different belt types, such as classical V-belts, narrow V-belts, or synchronous belts, have specific design and performance characteristics. The tensioner should be compatible with the chosen belt type and size. Consider factors such as belt width, profile dimensions, and load capacity when selecting the tensioner.

Evaluate the available space and mounting options in the application. The tensioner should be sized to fit within the available space and align properly with the pulleys. Consider factors such as the tensioner’s dimensions, mounting configurations (e.g., fixed, adjustable, spring-loaded), and accessibility for installation and maintenance.

Take into account the environmental conditions in which the V-belt system will operate. Factors such as temperature extremes, humidity, dust, and chemical exposure can impact the performance and longevity of the tensioner. Select a tensioner that is designed to withstand the specific environmental conditions of the application.

Refer to the manufacturer’s specifications and guidelines for the tensioner. Manufacturers often provide detailed information on tensioner selection, including tension force ranges, belt compatibility, operating limits, and installation instructions. Consult these resources to ensure the chosen tensioner meets the application requirements and aligns with industry standards.

Evaluate the tensioner’s maintenance and serviceability requirements. Consider factors such as the ease of tension adjustment, access for inspection and maintenance, and the availability of replacement parts. A tensioner that is easy to maintain and service can contribute to the longevity and reliability of the V-belt system.

Finally, consider the cost and long-term value of the tensioner. Evaluate factors such as the initial purchase cost, expected lifespan, and the overall value provided by the tensioner in terms of performance, reliability, and maintenance requirements. While it’s important to consider budget constraints, prioritize selecting a tensioner that meets the application requirements and offers long-term value rather than solely focusing on the upfront cost.

By following these guidelines and considering the specific requirements of the V-belt application, you can select and size V-belt tensioners that are well-suited for the intended use. Remember to consult manufacturers’ specifications and guidelines for detailed information and to ensure proper integration and optimal performance of the tensioner within the V-belt system.

Can you describe the various types of V-belt tensioners, such as spring-loaded or automatic tensioners?

There are several types of V-belt tensioners available, each designed to provide and maintain the proper tension in V-belt systems. Two commonly used types of V-belt tensioners are spring-loaded tensioners and automatic tensioners. Here’s a detailed description of each type:

- Spring-Loaded Tensioners:

- Automatic Tensioners:

Spring-loaded tensioners, also known as mechanical tensioners, utilize a spring mechanism to apply and maintain the tension in the V-belt. These tensioners consist of a pulley or a set of pulleys mounted on an adjustable arm. The arm is attached to a spring that exerts a pre-determined force on the pulley(s), creating the necessary tension in the V-belt.

Spring-loaded tensioners are designed to compensate for variations in belt length due to factors such as wear, temperature changes, or component movement. As the V-belt stretches or wears over time, the spring-loaded tensioner automatically adjusts the tension to keep the belt within the optimal operating range. This type of tensioner allows for manual adjustment as well, by using the adjustable arm to fine-tune the tension if necessary.

Spring-loaded tensioners are commonly used in a variety of applications, including automotive engines, industrial machinery, and HVAC systems. They are relatively simple in design, cost-effective, and provide reliable tensioning for V-belt systems.

Automatic tensioners, also known as self-adjusting tensioners, are designed to continuously monitor and adjust the tension in V-belt systems automatically. These tensioners incorporate a combination of mechanical and hydraulic or pneumatic components to achieve automatic tensioning.

Automatic tensioners typically include a pulley or a set of pulleys mounted on an arm or a housing. The tensioner assembly is equipped with a mechanism that senses the tension of the V-belt and adjusts the position of the pulley(s) accordingly. This mechanism can be hydraulic, pneumatic, or a combination of both. It senses the belt tension through load sensors, position sensors, or other means, and actuates the tensioner to maintain the optimum tension.

Automatic tensioners offer the advantage of continuous and precise tension control, ensuring that the V-belt operates within the optimal tension range at all times. They are commonly used in applications where maintaining consistent and accurate tension is critical, such as high-speed machinery, heavy-duty industrial equipment, and precision systems.

Both spring-loaded tensioners and automatic tensioners serve the purpose of maintaining proper tension in V-belt systems. The choice between the two depends on the specific requirements of the application, including the desired level of tension control, the operating conditions, and the budget constraints. Manufacturers and engineers consider factors such as belt load, speed, environmental conditions, and system dynamics when selecting the appropriate type of V-belt tensioner for optimal belt functionality.

editor by CX 2023-12-27

China high quality U Groove Plastic Pulley Bearing (ML-AU013) with Best Sales

Product Description

Product Description

1. Item No.: as shown in the picture.

2. Material: steel/zinc/aluminum/plastic bracket + ball bearing / needle bearing wheel

3. For some models, the height of the roller is adjustable.

4. Color of the wheel: red, green, white, orange, etc.

5. Application: sliding door and window, binds, rolling shutters, furniture, conveyor belt, etc.

6. Normal packing: poly bag + outer carton

About us

Our factory is specialized in manufacturing non-standard bearing, plastic and metal pulley, bracket pulley, roller, door and window fittings, etc. Relying on a series of advanced processing equipments, skilled workers, strict inspection system, and organized management, we are able to provide good-quality products with competitive price.

Product Categories

Contact Us:

HangZhou CZPT Pulley Manufacture Co., Ltd.

WEB: http://nbminli /

ADDRESS: No.9 CZPT Road, CZPT Industrial Zone, Xihu (West Lake) Dis. District, HangZhou, China

FAQ

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a quotaion in the shortest time?

A: When you send us an enquiry, please try to provide more details, such as product size, photo or drawing, order quantity, etc.

Q: How to start an OEM project with your company?

A: Please send us your designed drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange sample production once received your deposit .

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. Nomally our company MOQ is 10000pc , but it can be much more or less depending on different product types. Therefore, we recommend you to tell us your required quantity first.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. The lead time varies from 30 to 90 days.’

Why choose us

1. Professional experience: almost 20 years’ expenience in non-standard bearings, rollers, pulleys, and other plastic accessories for door and window.

2. Popular over the world: over 20 market countries.

3. Advantage: good quality with competitive price.

4. OEM offered: technical drawings, samples or photos are needed.

For more information, please visit http://nbminli /

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small (28-55mm) |

| Material: | Bearing Steel |

| Load Direction: | Radial Bearing |

| Separated: | Separated |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Overview of Different Types of Pulleys

A pulley is a wheel mounted on a shaft or shaft. Its purpose is to facilitate the movement or change of direction of the cable or taut rope, and to transmit power between the cable and the shaft. Pulleys are typically used for lifting, winding or forklift applications. If you are building your own pulley system, the following design and installation considerations should be followed. This article will give you an overview of the different types of pulleys.

Pulley System Mechanics

There are many different ways to utilize the mechanism of the pulley system. The most basic pulley system consists of a fixed wheel and a support frame. Both components are connected by ropes or cables used to support the load. A pulley system is effective when the force required to lift the load is less than the weight of the object being lifted.

One way to use a pulley system is to suspend a block with a mass of 0.80 kg on a fixed pulley. Then another person can hang a bucket weighing up to 40kg. The weight of the bucket is transferred to the fixed pulley. The rope is attached to the pulley by a loop or sling. The rope will spin and pull on the barrel or block.

The pulley system is also an important tool for lifting heavy objects. Pulleys are often used in construction equipment to make lifting heavy objects easier. Gun tackles, yard tackles, and stationary tackle systems are common examples of these devices. They use the mechanical advantage of the design to guide the force that lifts the object. If you want to learn more about pulley systems, visit Vedantu. This website will provide you with a full description of the mechanism and its application.

Types of pulleys

Many different types of pulleys are used to lift heavy objects. They change the direction of the force and are an integral part of the cable system. Therefore, pulleys can move large and heavy objects more easily. However, before buying a pulley, you should have an idea of the benefits it brings. Below are some of the most common uses for pulleys.

Conical Pulley: Consists of several small conical pulleys connected to each other. The larger base of one pulley is used to guide the force. Round pulleys are used in the same way as step pulleys. They are widely used in industry and can be purchased at any hardware store. Pulleys are a huge investment, and the benefits they provide far outweigh the cost.

Movable Pulls: These are similar to their names, but work by allowing objects to move with the pull. Their movable parts are attached to the object to be lifted. They are also ideal for lifting heavy loads and can be found in utility elevators and construction cranes. They are also used in many other industries. They can also be made of wood, plastic or metal. The type of pulley you use depends on its intended use.

Mechanical Advantages of Pulley Systems

A pulley system is a simple machine that reduces the effort required to lift heavy loads. This mechanical advantage is proportional to the number of loops. For example, if you have a single rope loop, you must apply equal force to lift the weight. When you add another rope loop, you can lift heavier weights just by applying the same force. Therefore, a pulley system is an excellent way to use gravity to your advantage.

Mechanical advantage is a measure of the effectiveness of a pulley system. This ratio of force to work is called the mechanical advantage. In other words, if the rope system has a large mechanical advantage, it means that it requires less force to lift heavier loads. This advantage is usually measured in kilograms and is the same for all pulley systems. In general, the greater the mechanical advantage, the less effort is required to lift the load.

The mechanical advantage of a pulley system is that a single movable pulley requires half the force to lift an object than a single fixed pulley. Assuming frictionless bearings, the MA of a single pulley system is 2, similar to the MA of a single lever. A single pulley travels twice as much as it takes to move heavy objects manually.

Considerations when designing and installing a pulley system

The capacity of the pulley depends on the type and diameter of the cable. Besides its diameter, its sheath should also support it well. The basic function of the pulley is also important. However, most people tend to ignore the pulley selection process, resulting in ineffective load-pull capabilities. To avoid such problems, different parameters must be carefully considered during design and installation.

During the design and installation of the pulley system, the ratio of the cable diameter to the largest pulley diameter must be considered. Those who work in the industrial sector will have an idea of this ratio. The greater the D:d ratio, the greater the capacity of the cable to withstand the load. The best way to ensure secure design is to take the right information and use it to design a system that is both robust and secure.

When designing a pulley system, it is important to remember that the pulley needs to have enough power to operate safely. In addition to horsepower, the belt should have sufficient elongation to absorb shock loads. If the elongation of the belt is very small, it is very likely that the teeth will be sheared or broken, causing serious damage to the system. Extensive belt sag should be compensated for by offsetting the driven pulley. Finally, the frame supporting the pulley should be rigid. Otherwise, the non-rigid frame will cause center distance and tooth skipping changes.

Add more pulleys to the system

Adding more pulleys to the spool might have some effect. The friction between the rope and the pulley increases with the number of pulleys, which in practice limits the number of spools. The best solution is to combine the pulleys into one housing. If the load is small enough, adding a few pulleys probably won’t make a difference.

Using multiple pulleys allows a single load to be lifted with half the force required. The longer the rope, the greater the mechanical advantage. In fact, a spool can withstand a load of 100 N. Additionally, adding more pulleys quadrupled the mechanical advantage. In this case, a single 100 N load would require a force of 25 Newtons.

When the rope is used, it stretches as the weight of the object increases. This will make the rope longer, increasing its length and increasing the distance over which the load can be lifted. Eventually, the rope will break and the lifted object will fall. Then you will have to buy a new rope. It may seem like an expensive proposition, but it pays off in the long run.

cast iron pulley

Cast iron pulleys are the most popular choice among industrial users. They are made of solid cast iron and usually cost very little. Their rims are held in place by a mesh that extends from a central boss. They also have spokes and arms that hold them in place. These pulleys are ideal for a variety of applications including fan belts, compressors and conveyors.

V-groove drive pulleys are ideal for general purpose pulleys. It has an inner diameter of one inch and is commonly used in feeders and ventilation curtain systems. Its steel straps prevent rust and ensure it meets or exceeds industry standards. 3-1/2″ cast iron pulleys are also available. In addition to the V-groove drive pulley, there are similar pulleys for power transmission. The V-groove drive pulley is powder coated for added durability.

The cross section of the arm is elliptical, with the long axis twice as long as the short axis. The radius of the arm is equal to the diameter of the pulley. The thickness of the arm is a key factor to consider when purchasing a pulley. If you’re not sure which material you need, you can always consider wooden or steel pulleys. They are lighter and have a higher coefficient of friction than metal pulleys.

timing pulley

Plastic timing pulleys have many advantages over steel timing pulleys. On the one hand, they are lightweight and corrosion resistant, making them ideal for applications that do not require high torque and tensile strength. Another benefit is their resistance to high temperatures. Plastic timing pulleys are ideal for applications involving flammable gases, solvents or particles. They can last for many years. For more information on the different types of plastic timing pulleys.

Vertical shaft drives require flanged timing pulleys. For large span drives, at least one of these pulleys must be flanged. The flange provides a secure connection to the shaft and prevents ratcheting of the timing belt. Finally, HTD timing belt teeth prevent timing belt ratcheting. These teeth need a large enough space to be seated. However, they can also cause a backlash. These pulleys are not suitable for applications where positional accuracy is critical.

Timing belt systems are designed to avoid such problems. The drive shaft and the driven shaft are aligned with each other. The pulleys are located on different planes and are connected by pitch lines. The pitch line of the timing pulley coincides with the pitch line of the belt. These pulleys are also easier to implement and maintain. It is better to use a synchronous system because the resulting gear system emits less noise than other systems.

editor by CX

2023-07-12

China Professional Magnetic Pulley for Belt Conveyor Price pulley block

Product Description

Magnetic pulley for belt conveyor price

1. it an transport different weight goods, cartons, bags and other small pieces.

2. the material of conveyor belt is metal( such as stainless), thus the strength is strong, scalability

small, not easy deformation, easy maintenance, health, and can use in corrosion or bad environment sexual strong, long service life, and wide application.

3.It is applicable to food, non-staple food,frozen aquatic products processing production lines,packing conveyor line and electronic parts of heating, baking, and also suitable for pharmaceutical, daily-life

chemical and other industries.

Main Features:

Frame structure: stationary type, Mobile type

Texture of belt: rubber belt, plastic belt,steel core belt, PVC belt, PU belt etc.

Adopt corrosion resistant belt to convey reletive corrosive stuff, such as oil proof belt, anti-acid belt, alkali resisting belt.

4. Major Technical Parameters:

We can customize the equipment according to your needs

5. Our service

1. Our engineers can work separately according to the requirements of design for clients of the equipment. and send a customer confirmation to help customers to save costs.

2. During the manufacture of the equipment, we photograph product production progress, and sent to the customer to track the progress.

3. The goods hair go, we will send the original documents for the customer (such as packing list, bill, CO, Form E, Form A, Form F, Form M, B/L etc.)

4. We can provide customers with free English foundation drawing, installation drawings, manuals, maintenance manuals and parts drawings.

5. We can send our engineers to installation and debugging overseas, and free training of operators and maintenance workers.

6. We have a set of After sales service system, A ID will be sent to each customer, they can log in this system that view all information to buy equipment and parts by it. We provide 24-hour online consultation.

Electromagnetic Dry Powder Iron Separator /The Iron-Removing Magnetic Separation Equipment in Gypsum Powder Producti Lines

2. Characteristics

Main Features of belt conveyor system

The portable inclined belt conveyor has a simple structure, convenient maintenance, beautiful appearance, and reliable operation. rubber belt conveyor is widely used in the assembly and transportation of parts in electronics, home appliances, food, automobiles, motorcycles, and other industries.

1. The main conveying forms are strip table, independent table, unilateral table, bilateral table, and non-table table.

2. The forms of pvc belt conveyor drive are motor-driven conveying form.

3. The common width of the belt is: customized according to customer requirements.

4. The materials of conveyor belt are rubber belt, PVC belt, canvas belt, food belt, etc.

5. Conveyor belts include conveyor belts with baffles, belt boards, flat belts, and non-slip belts.

6. The size of the worktable is determined by the user.food grade belt conveyor

7. The work surface includes a fireproof board, ordinary rubber, antistatic rubber lamp.

8. The wire body support includes stainless steel, aluminum profile, carbon steel spraying, etc.

9. The conveying speed is generally: according to the needs of the user, the speed is adjusted or fixed.

10. Speed regulation includes frequency conversion, electromagnetic speed regulation, electronic speed regulation, mechanical speed regulation, etc.

11. Belt frame materials are carbon steel, stainless steel, aluminum profile

3. Related products

4. Certification

Quality is our life. Innovation is our power. In order to guarantee the quality of products and improve the environment, CZPT takes the lead to pass through the GB/T19001-ISO9001:2000 quality management system verification, ISO14001-2004 environmental management system verification and GB/T28001-2001 Occupational Health and Safety Management System verification. CZPT has fully controlled the entire process of manufacturing and development of 9 categories of products, and has formed a comprehensive, complete set of product R&D, manufacturing, test base.

5. Our Company

FAQ

Q1: What is the iron removing rate of your Magnetic Separators?

A: ABOVE 99%.

Q2: How about your delivery date?

A: 25-35 days.

Q3: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q4: What is the usual payment method?

A: T/T, Paypal, L/C, VISA, e-Checking,Western Union.

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q6: How can I get the quotation IN TIME?

A: For a timely and responsible quotation, please inform us more details as following:

1. What kind of material you are going to deal with?

2. What is the size of the materials?

3. What is the width of the conveying belt?

| Usage: | Mine |

|---|---|

| Type: | Magnetic Separator |

| Installation: | Horizontal |

| Current: | DC |

| Cooling Method: | Forced Air-Cooled |

| Automation: | Automatic |

| Customization: |

Available

| Customized Request |

|---|

How to use the pulley system

Using a pulley system is a great way to move things around your home, but how do you use a pulley system? Let’s look at the basic equations that describe a pulley system, the types of pulleys, and some safety considerations when using pulleys. Here are some examples. Don’t worry, you’ll find all the information you need in one place!

Basic equations of pulley systems

The pulley system consists of pulleys and chords. When the weight of the load is pulled through the rope, it slides through the groove and ends up on the other side. When the weight moves, the applied force must travel nx distance. The distance is in meters. If there are four pulleys, the distance the rope will travel will be 2×24. If there are n pulleys, the distance traveled by the weight will be 2n – 1.

The mechanical advantage of the pulley system increases with distance. The greater the distance over which the force is applied, the greater the leverage of the system. For example, if a set of pulleys is used to lift the load, one should be attached to the load and the other to the stand. The load itself does not move. Therefore, the distance between the blocks must be shortened, and the length of the line circulating between the pulleys must be shortened.

Another way to think about the acceleration of a pulley system is to think of ropes and ropes as massless and frictionless. Assuming the rope and pulley are massless, they should have the same magnitude and direction of motion. However, in this case the quality of the string is a variable that is not overdone. Therefore, the tension vector on the block is labeled with the same variable name as the pulley.

The calculation of the pulley system is relatively simple. Five mechanical advantages of the pulley system can be found. This is because the number of ropes supporting the load is equal to the force exerted on the ropes. When the ropes all move in the same direction, they have two mechanical advantages. Alternatively, you can use a combination of movable and fixed pulleys to reduce the force.

When calculating forces in a pulley system, you can use Newton’s laws of motion. Newton’s second law deals with acceleration and force. The fourth law tells us that tension and gravity are in equilibrium. This is useful if you need to lift heavy objects. The laws of motion help with calculations and can help you better understand pulley systems.

Types of pulleys

Different types of pulleys are commonly used for various purposes, including lifting. Some pulleys are flexible, which means they can move freely around a central axis and can change the direction of force. Some are fixed, such as hinges, and are usually used for heavier loads. Others are movable, such as coiled ropes. Whatever the purpose, pulleys are very useful in raising and lowering objects.

Pulleys are common in many different applications, from elevators and cargo lift systems to lights and curtains. They are also used in sewing machine motors and sliding doors. Garage and patio doors are often equipped with pulleys. Rock climbers use a pulley system to climb rocks safely. These pulley systems have different types of pinions that allow them to balance weight and force direction.

The most common type of pulley is the pulley pulley system. The pulley system utilizes mechanical advantages to lift weight. Archimedes is thought to have discovered the pulley around 250 BC. in ancient Sicily. Mesopotamians also used pulleys, they used ropes to lift water and windmills. Pulley systems can even be found at Stonehenge.

Another type of pulley is called a compound pulley. It consists of a set of parallel pulleys that increase the force required to move large objects. This type is most commonly used in rock climbing and sailing, while composite pulleys can also be found in theater curtains. If you’re wondering the difference between these two types of pulleys, here’s a quick overview:

Mechanical Advantages of Pulley Systems

Pulley systems offer significant mechanical advantages. The ability of the system to reduce the effort required to lift weights increases with the number of rope loops. This advantage is proportional to the number of loops in the system. If the rope had only one loop, then a single weight would require the same amount of force to pull. But by adding extra cycles, the force required will be reduced.

The pulley system has the advantage of changing the direction of the force. This makes it easier to move heavy objects. They come in both fixed and mobile. Pulleys are used in many engineering applications because they can be combined with other mechanisms. If you want to know what a pulley can do, read on! Here are some examples. Therefore, you will understand how they are used in engineering.

Single-acting pulleys do not change direction, but compound pulleys do. Their mechanical advantage is six. The compound pulley system consists of a movable pulley and a fixed pulley. The mechanical advantage of the pulley system increases as the number of movable wheels decreases. So if you have two wheels, you need twice as much force to lift the same weight because you need a movable pulley.

The mechanical advantage of a pulley system can be maximized by adding more pulleys or rope lengths. For example, if you have a single pulley system, the mechanical advantage is one of the smallest. By using two or three pulleys, up to five times the mechanical advantage can be achieved. You can also gain up to ten times the mechanical advantage by using multiple pulley systems.

The use of a single movable pulley system also adds to the mechanical advantage of the pulley system. In this case, you don’t have to change the direction of the force to lift the weight. In contrast, a movable pulley system requires you to move the rope farther to generate the same force. Using a compound pulley system allows you to lift heavy loads with ease.

Safety Issues When Using Pulley Systems

Pulleys have an incredibly unique structure, consisting of a disc with a groove in the middle and a shaft running through it. A rope or cord is attached to one end of a pulley that turns when force is applied. The other end of the rope is attached to the load. This mechanical advantage means that it is much easier to pull an object using the pulley system than to lift the same object by hand.

Although pulley systems are a common part of many manufacturing processes, some employers do not train their workers to use them properly or install protection to prevent injury. It is important to wear proper PPE and follow standard laboratory safety practices during pulley system activities. Make sure any support structures are strong enough to handle the weight and weight of the rope or rope. If you do fall, be sure to contact your employer immediately.

editor by CX

2023-07-11

China OEM CZPT Machine Part V-Grooved Pulley (04508063) for (BF1013) engine pulley

Product Description

Company profile

As the main and big supplier & manufacturer of CZPT engine parts in China . we can provide parts for CZPT 912/913/914/1013/2012/2013/1011/2011/413/513/1015/226B series engines .

we have our own technology to develop and produce the CZPT fuel pump , coolant pump , shutdown device , 1011/2011 timing belt kit & oil pump .

High quality & larger inventory & competitive price are our advantages .

Parts List

Photos of our Products :

Photos of our others parts

Packages for shipping

| Certification: | ISO9001 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Iron |

| Type: | V-Grooved Pulley |

| Quality: | High Quality |

Calculate the ideal mechanical advantage of pulleys

The basic equations for pulleys can be found in this article. It will also cover the different types of pulleys, the ideal mechanical advantages of pulleys, and some common uses of pulley systems. Read on to learn more! After all, a pulley is a simple mechanical device that changes the direction of a force. Learn more about pulleys and their common uses in engineering.

pulley basic equation

Pulleys work the same way as gravity, so they should withstand similar forces. Newton’s laws of motion can be used to calculate the forces in a pulley system. The second law of motion applies to forces and accelerations. Similar to this is Newton’s third law, which states that the directions of forces are equal and opposite. The fourth law dictates the direction of force. The Fifth Law states that tension is in equilibrium with gravity.

A pulley is a simple mechanism that transmits force by changing direction. They are generally considered to have negligible mass and friction, but this is only an approximation. Pulleys have different uses, from sailboats to farms and large construction cranes. In fact, they are the most versatile mechanisms in any system. Some of their most common applications and equations are listed below.

For example, consider two masses m. Those of mass m will be connected by pulleys. The static friction coefficient of the left stop is ms1, and the static friction coefficient of the right stop is ms2. A no-slip equation will contain multiple inequalities. If the two blocks are considered to be connected by a pulley, the coefficient of kinetic friction is mk. In other words, the weight of each block carries the same mass, but in the opposite direction.

Types of pulleys

A pulley is a device used to pull and push objects. Pulley systems are ropes, cables, belts or chains. The “drive pulley” is attached to the shaft and moves the driven pulley. They are available in a variety of sizes, and the larger they are, the higher the speed of power transmission. Alternatively, use small pulleys for smaller applications.

Two-wheel pulleys have two mechanical advantages. The greater the mechanical advantage, the less force is required to move the object. More wheels lift more weight, but smaller pulleys require less force. In a two-wheel pulley system, the rope is wound around two axles and a fixed surface. As you pull on the rope, the shafts above slowly come together.

Compound pulleys have two or more rope segments that are pulled up on the load. The mechanical advantage of compound pulleys depends on the number of rope segments and how they are arranged. This type of pulley can increase the force by changing the direction of the rope segment. There are two main types of pulleys. Composite pulleys are most commonly used in construction. The ideal mechanical advantage of pulleys is 2 or more.

Construction pulleys are a basic type. They are usually attached to wheel rails and can be lifted to great heights. Combinations of axes are also common. Construction pulleys can be raised to great heights to access materials or equipment. When used in construction, these pulleys are usually made of heavy materials such as wood or metal. They are secured with ropes or chains.

The ideal mechanical advantage of pulleys

The pulley system is a highly complex system with high mechanical advantages. Use a single pulley system to reduce the force required to lift an object by cutting it in half. The mechanical advantage increases as you add more pulleys, such as six or seven. To calculate the mechanical advantage of a pulley system, you need to count the number of rope segments between the pulleys. If the free end of the rope is facing down, don’t count it. If it’s facing up, count. Once you have your number, add it up.

The required mechanical advantage of a pulley is the number of rope segments it has to pull the load. The more rope segments, the lower the force. Therefore, the more rope segments the pulley has, the lower the force. If the rope segments are four, then the ideal mechanical advantage is four. In this case, the composite pulley quadrupled the load force.

The ideal mechanical advantage of a pulley system is the sum of the mechanical force and the force required to lift the load at its output. Typically, a single pulley system uses two ropes, and the mechanical force required to lift the load is multiplied by the two ropes. For a multi-pulley system, the number of ropes will vary, but the total energy requirement will remain the same. The friction between the rope and pulley increases the force and energy required to lift the load, so the mechanical advantage diminishes over time.

Common uses of pulley systems

A pulley system is a simple mechanical device typically used to lift heavy objects. It consists of a rotating wheel attached to a fixed shaft and a rope attached to it. When the wheel moves, the force applied by the operator is multiplied by the speed of the pulley, and the force is multiplied by the weight of the object being lifted. Common uses for pulley systems include pulling, lifting, and moving heavy objects.

The oil and petroleum industries use pulley systems in a variety of applications. Most commonly, pulleys are used in drilling operations and they are installed on top of the rig to guide the cable. The cable itself is attached to two pulleys suspended in the derrick, where they provide mechanical energy to the cable. Using a pulley system in this application provides the force needed to move the cable safely and smoothly.

The main advantage of the pulley system is that it minimizes the force required to lift an object. The force used to lift the object is multiplied by the desired mechanical advantage. The more rope segments, the lower the force required. On the other hand, a compound pulley system can have many segments. Therefore, a compound pulley system can increase the force a worker can exert on an object.

Safety Precautions to Take When Working on Pulley Systems

There are many safety precautions that should be observed when working on a pulley system. The first is to wear proper protective gear. This includes hard hats that protect you from falling objects. Also, gloves may be required. You should limit the amount of movement in the penalty area, and you should also keep the area free of unnecessary people and objects. Also, remember to wear a hard hat when working on the pulley system.

Another important safety precaution when working on a pulley system is to check the Safe Working Load (SWL) of the pulley before attaching anything. This will help you understand the maximum weight the pulley can hold. Also, consider the angle and height of the pulley system. Always use safety anchors and always remember to wear a hat when working on a pulley system.

Safe use of chain hoists requires training and experience. It is important to read the manufacturer’s manual and follow all safety precautions. If you’re not sure, you can actually inspect the hoist and look for signs of damage or tampering. Look for certifications for sprocket sets and other lifting accessories. Look for the Safe Working Load (SWL) marking on the chain hoist.

Example of a pulley system

Pulley systems are often used to lift items. It allows you to reduce the effort to lift and move the load by applying force in one direction. Pulley systems can be built and modeled to fit any type of project. This resource focuses on pulley systems and is designed to support the new GCSEs in Engineering, Design and Technology. There are also many examples of pulley systems suitable for various applications.

In the study, participants who read easy text took longer to manipulate the pulley system than those who read challenging text. In general, this suggests that participants with prior scientific experience used their cognitive abilities more effectively. Additionally, students who read simple texts spent less time planning the pulley system and more time on other tasks. However, the study did show that the time required to plan the pulley system was similar between the two groups.

In everyday life, pulley systems are used to lift various objects. Flagpoles are one of many pulley systems used to raise and lower flagpoles. They can also be used to raise and lower garage doors. Likewise, rock climbers use pulleys to help them ascend and descend. The pulley system can also be used to extend the ladder.

editor by CX

2023-07-07

China Professional Factory Price Aluminum Gt2 Timing Belt Pulley for Transmission Machine pulley block

Product Description

NEED TO KNOW BEFORE BUYING

This product is a customized product, please order the size you need or you have industrial drawings to consult customer service staff before placing an order, welcome to inquire

| Pulley Sizes: | Customizable |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Industrial Assembly Line |

| Delivery Time: | 7-10days |

| Customization: |

Available

| Customized Request |

|---|

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations

There are several safety considerations to consider when using pulleys. The first is Secure Workload (SWL). This value is a general guideline for the maximum weight a pulley can safely handle. It varies according to the height and angle of the pulley. Besides SWL, there are some other factors to consider. Consider each one before deciding on the pulley that best suits your needs.

Another safety consideration is the weight of the load. Since the highs of the pulley are higher than the lows, it doubles in weight. The weight of the high point should not exceed 4 kN. The safety factor is calculated by multiplying the strength of the pulley by the weight of the load. Secondary COD has a safety factor of 10:1 and bulletproof primary anchors should be used with pulleys.

If using a chain hoist, you must be trained in the appropriate type of lifting. It is important not to hang on the top hooks of the structure, nor to overload or rig the hooks with multiple slings. You should also avoid corroded or damaged chains, as they can cause the crane to jam or overload. A worn chain can even cause the load to drop.

Components of a pulley system

Proper design of the pulley system can increase the life of the cables and pulleys. Larger diameter cables should be selected as they are more durable than smaller diameter cables. The cables should also be supported in the pulley grooves. The pulley must be designed to be compatible with the cable and its lubrication should be optimal. Proper lubrication of cables and pulleys will ensure maximum durability and longevity.

The first type of pulley is called a fast pulley. These pulleys are used for quick start and stop of the machine. These pulleys are usually mounted in pairs on the countershaft of the machine. One pulley is tightly mounted on the machine shaft, while the other pulley is fitted with a free-spinning mechanism. When the machine is running, the belt is mounted on the tensioner pulley, and when it is stopped, the belt slides on the independent pulley.

Composite pulley sets reduce the overall effort required by reducing the size of the pulley. These are usually attributed to Archimedes. Flat pulleys are often used in flat belt driven transmission systems. These are used in high-speed, low-power applications. Flat pulley idlers are also used on the back of traditional V-belts.

editor by CX

2023-06-13

China high quality Low Noise High Precision Single Row Type U Red Size 5.8*20.5*8.2*18.2mm Pulley wholesaler

Product Description

Detailed Photos

Product Description

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CZPT was dedicated in research, development and manufacture of bearings. Now, CZPT has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller’s outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they’re made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click “Contact supplier” to contact us, or “Call us” with any questions that you may have.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Casting |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to use the pulley system

Using a pulley system is a great way to move things around your home, but how do you use a pulley system? Let’s look at the basic equations that describe a pulley system, the types of pulleys, and some safety considerations when using pulleys. Here are some examples. Don’t worry, you’ll find all the information you need in one place!

Basic equations of pulley systems

The pulley system consists of pulleys and chords. When the weight of the load is pulled through the rope, it slides through the groove and ends up on the other side. When the weight moves, the applied force must travel nx distance. The distance is in meters. If there are four pulleys, the distance the rope will travel will be 2×24. If there are n pulleys, the distance traveled by the weight will be 2n – 1.

The mechanical advantage of the pulley system increases with distance. The greater the distance over which the force is applied, the greater the leverage of the system. For example, if a set of pulleys is used to lift the load, one should be attached to the load and the other to the stand. The load itself does not move. Therefore, the distance between the blocks must be shortened, and the length of the line circulating between the pulleys must be shortened.

Another way to think about the acceleration of a pulley system is to think of ropes and ropes as massless and frictionless. Assuming the rope and pulley are massless, they should have the same magnitude and direction of motion. However, in this case the quality of the string is a variable that is not overdone. Therefore, the tension vector on the block is labeled with the same variable name as the pulley.

The calculation of the pulley system is relatively simple. Five mechanical advantages of the pulley system can be found. This is because the number of ropes supporting the load is equal to the force exerted on the ropes. When the ropes all move in the same direction, they have two mechanical advantages. Alternatively, you can use a combination of movable and fixed pulleys to reduce the force.

When calculating forces in a pulley system, you can use Newton’s laws of motion. Newton’s second law deals with acceleration and force. The fourth law tells us that tension and gravity are in equilibrium. This is useful if you need to lift heavy objects. The laws of motion help with calculations and can help you better understand pulley systems.

Types of pulleys

Different types of pulleys are commonly used for various purposes, including lifting. Some pulleys are flexible, which means they can move freely around a central axis and can change the direction of force. Some are fixed, such as hinges, and are usually used for heavier loads. Others are movable, such as coiled ropes. Whatever the purpose, pulleys are very useful in raising and lowering objects.

Pulleys are common in many different applications, from elevators and cargo lift systems to lights and curtains. They are also used in sewing machine motors and sliding doors. Garage and patio doors are often equipped with pulleys. Rock climbers use a pulley system to climb rocks safely. These pulley systems have different types of pinions that allow them to balance weight and force direction.

The most common type of pulley is the pulley pulley system. The pulley system utilizes mechanical advantages to lift weight. Archimedes is thought to have discovered the pulley around 250 BC. in ancient Sicily. Mesopotamians also used pulleys, they used ropes to lift water and windmills. Pulley systems can even be found at Stonehenge.

Another type of pulley is called a compound pulley. It consists of a set of parallel pulleys that increase the force required to move large objects. This type is most commonly used in rock climbing and sailing, while composite pulleys can also be found in theater curtains. If you’re wondering the difference between these two types of pulleys, here’s a quick overview:

Mechanical Advantages of Pulley Systems

Pulley systems offer significant mechanical advantages. The ability of the system to reduce the effort required to lift weights increases with the number of rope loops. This advantage is proportional to the number of loops in the system. If the rope had only one loop, then a single weight would require the same amount of force to pull. But by adding extra cycles, the force required will be reduced.

The pulley system has the advantage of changing the direction of the force. This makes it easier to move heavy objects. They come in both fixed and mobile. Pulleys are used in many engineering applications because they can be combined with other mechanisms. If you want to know what a pulley can do, read on! Here are some examples. Therefore, you will understand how they are used in engineering.

Single-acting pulleys do not change direction, but compound pulleys do. Their mechanical advantage is six. The compound pulley system consists of a movable pulley and a fixed pulley. The mechanical advantage of the pulley system increases as the number of movable wheels decreases. So if you have two wheels, you need twice as much force to lift the same weight because you need a movable pulley.

The mechanical advantage of a pulley system can be maximized by adding more pulleys or rope lengths. For example, if you have a single pulley system, the mechanical advantage is one of the smallest. By using two or three pulleys, up to five times the mechanical advantage can be achieved. You can also gain up to ten times the mechanical advantage by using multiple pulley systems.

The use of a single movable pulley system also adds to the mechanical advantage of the pulley system. In this case, you don’t have to change the direction of the force to lift the weight. In contrast, a movable pulley system requires you to move the rope farther to generate the same force. Using a compound pulley system allows you to lift heavy loads with ease.

Safety Issues When Using Pulley Systems

Pulleys have an incredibly unique structure, consisting of a disc with a groove in the middle and a shaft running through it. A rope or cord is attached to one end of a pulley that turns when force is applied. The other end of the rope is attached to the load. This mechanical advantage means that it is much easier to pull an object using the pulley system than to lift the same object by hand.

Although pulley systems are a common part of many manufacturing processes, some employers do not train their workers to use them properly or install protection to prevent injury. It is important to wear proper PPE and follow standard laboratory safety practices during pulley system activities. Make sure any support structures are strong enough to handle the weight and weight of the rope or rope. If you do fall, be sure to contact your employer immediately.

editor by CX

2023-06-12

China best Black Color Flexible Made in China Ceramic Height Adjustment Pulley Block alternator pulley

Product Description

Product Description

| Item No. | HL01 |

| Product Size | 58MM*145MM |

| Rated Voltage&Current | / |

| Life Span | 100,000 times/2-year warranty |

| Material | Porcelain |

| Color | White, black, brown, grey, etc. (various colors are optional for the porcelain housing) |

| Suitable for | Living room/Bedroom/Dining room/Corridor |

| Packing Style | Inner box + shipping box |

| OEM/ODM | Always be welcomed |

Detailed Photos

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated|

|

|---|

| Warranty: | 3 Years |

|---|---|

| Type: | Wire Rope Sling |

| Material: | Porcelain |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

The Mechanical Advantage of a Pulley

A pulley is an important tool for many tasks. The advantage that it offers over a hand-held mechanism is its mechanical advantage. In this article, we’ll discuss the types of pulleys and their applications. We’ll also look at the types of compound pulleys. And, of course, there’s a little bit about the mechanical advantage of a pulley. This article will help you decide whether this tool is right for your needs.

Mechanical advantage of a pulley

A pulley has a mechanical advantage over a lever because it is able to produce more force over longer distances. The mechanical advantage of a pulley sounds brilliant and could produce energy. But what exactly is this mechanical advantage? Let’s take a look. First, consider how a pulley works. A rope supports a 100kg mass, which requires 500 newtons of force to lift. If the rope supports a 100kg mass, two sections of rope can support that load. Using a pulley, you can lift the same weight with half the force.

A pulley’s ideal mechanical advantage is the ratio of the force applied to the total length of the rope. The larger the radius, the greater the mechanical advantage. A pulley made up of four rope segments has an ideal mechanical advantage of four. Therefore, a four-segment pulley would multiply the force applied by four. As the numbers on the rope segments are smaller than the total length of the rope, it would be better to use a compound pulley.

The mechanical advantage of a pulley can be calculated by using the T-method. The first step in calculating the mechanical advantage of a pulley is defining the force you need to lift. Then, divide that force by two to calculate the amount of force you need to lift the load. Once you know this amount, you can design a pulley to meet your needs. That way, you can achieve the perfect balance between the two types of pulleys.

Types of pulleys

The main function of the pulley is to change the direction of the force. The mechanical advantages of a single pulley are two. Ideally, two pulleys should have two or more mechanical advantages. The mechanical advantage of compound pulleys can be increased to two or more. The number of pulleys that make up the composite pulley will determine the mechanical advantage. Certain types of pulleys are combined in one housing.

A stepped pulley is a set of pulleys with stepped surfaces. Each face is anchored to the mid-axis in an ordered sequence. This design gives these pulleys their name. They are used to increase and decrease the speed of the driven pulley. Step pulleys are usually used in pairs. They can be straight or stepped, but usually come in pairs.

The three main types of pulleys are pulleys, rope pulleys, and chain pulleys. Pulley Pulley systems use mechanics to lift and lower heavy objects. The Greek historian Plutarch credits the invention of the pulley to Archimedes of ancient Sicily. The Mesopotamians used rope pulleys to lift water around 1500 BC, and Stonehenge is said to have been built using a rope pulley system.

Application of pulley system

The advantages of using a pulley system are numerous. The ability to lift heavy objects is a good example. The pulley system makes it easy for people to lift blocks and other large objects. It can be used in many different applications, from utility elevators to construction cranes. In addition, it is widely used on sailing boats. If you want to learn more about the benefits of a pulley system, keep reading!

You can use the pulley system to water flowers or water plants. Some of them even lowered the pot to make cleaning easier. Pendant lights are another great place to install a pulley system. Climbing and fishing are just some of the activities that utilize the pulley. They are great for fishing and gardening. And since they are so versatile, you can use the pulley system anywhere.

To get the most out of your pulley system, you must choose a product that has all of the above attributes. A high-quality pulley must have a large pulley diameter and be made of sturdy materials. The cables must also be properly supported in the pulleys to ensure a long service life for your investment. A good cable should have minimal cracks and be lubricated. These factors are the most important considerations when choosing a pulley system for your needs.

composite pulley

Composite pulley systems combine two or more movable pulleys. These systems maximize the force to move the weight and can also change direction so they can be used to lift weights. Composite pulley systems can be as simple or as complex as your needs. For example, a pulley pulley system uses multiple pulleys on each axis. This method is often used for hoisting building materials.

A compound pulley system has two or more rope segments, each of which is pulled up on a load. It can increase lift by making objects move faster. These systems are common on large sailboats and construction sites. Composite pulleys are also available for larger boats. Due to their versatility, they are versatile tools for construction sites and large sailboats. If you have their app, you should consider buying one.

The main advantage of composite pulleys is their versatility. You can use them to lift weights or use them to save energy. Composite pulleys are especially useful for lifting heavy objects. For example, you can tie a paper clip to the end of the rope and pull it up. The flag is then lifted into the air with the help of compound pulleys. Composite pulleys are a great invention and they are often used in construction.

security considerations